hunterdan

Well-Known Member

- Joined

- Apr 13, 2009

- Location

- Morganton,NC

Your scaring me...just kidding thanks for the info.I worked at a machine shop years ago. Headwork was what I did the most of. All engines have a cut off as to how much can be machined off of them. Before I ever surfaced one, I used a dial indicator to check it to see how much would have to machined off to square and clear up the surface. This was for heads that were being gone through and or owner wanted it checked due to a blown head gasket. Race engines were a whole other story. "If" the reman person of your head did as I did, then there should be no problem with just replacing the head with a quality head gasket. If the cut till it cleared, tat may be an issue. Not sure about the AMC 258, but some engines you can get thicker head gaskets to compensate for more being cut off that should have been. About the only way to check to see if too much has been cut off, is to cc the heads combustion chamber.

Will doI used a felpro stock style head gasket. It's still working so I guess it's a good one. Most important thing is to follow that torque sequence and put liquid ptfe on the front drivers side head bolt threads.

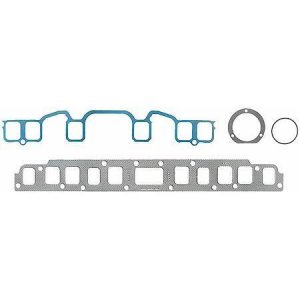

I was wondering about gasket. Gasket that I removed was a thick soft silver type.Oh and use the good felpro gasket for the intake and exhaust with a good coat of copper spray on the paper side.

Yep, I was looking at those. The kit was about $80. I'm just going to get one in my rods range for $8-10.use a push rod length checking tool to verify.

I would also be sure to drain the lifters in case any are stuck, simple to take apart and drain. Be sure to rotate the engine assembly when you prime the oil pump to get all the air out.

Don't know about draining lifters. You mean drain oil? I will be rotating the engine as I set TDC on intake stroke - - (Is that right) for each set of rockers and torquing