MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

I think the packaging around the CV doesn't matter at all, because you're not going to have enough steer angle with the monoball in that orientation. Might be marginal at normal ride height, but then you have compound angles in bump and droop that might not get you where you want to be. I'm going to play the "there is a reason why front ball joints are oriented like that" card.

Why is tapping not an option? That's pretty common to do for a steered upright like that, with a retaining tab/plate/bracket whatever to capture the bolt head to prevent it from turning and falling out. Make sure that whatever orientation you use that the monoball is mounted in double-shear, which is normally just a machined pocket to capture the monoball on both sides. I'm not sure if you need as tall of a misaligntment stack as you think you need, depending on what type of clearance you have around the monoball.

I'm gonna try to rotate the outboard uni-ball cups somewhat horizontal with the earth. The extreme angle is 28.75 degrees on that lower outboard joint at droop. If I can get it to work, I'll probably end up changing the misalignment stack height to 3.5 inches throughout the entire car.

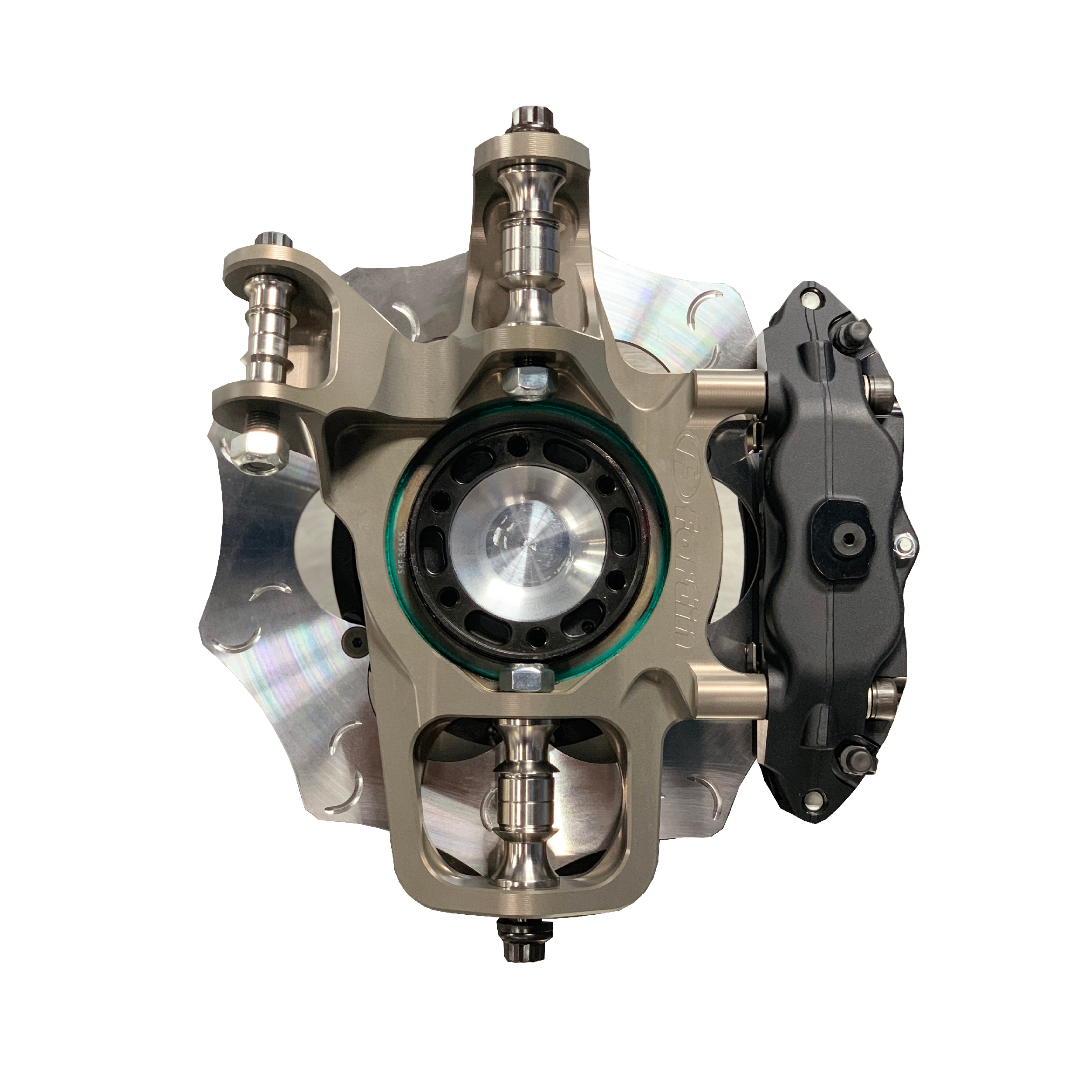

Portal IFS uprights. From same companies mentioned above, who also sell bulkheads, and can also provide a-arms...

I guess one could argue that I've either spent 2 weeks, or 6 months on this lower control arm. I know Dan Dubose isn't going to want any of this Motobilt stuff coming off his laser machine looking like cheese factory. I feel like I put a lot of effort into it, and you guys helped make it. Thanks.

I guess one could argue that I've either spent 2 weeks, or 6 months on this lower control arm. I know Dan Dubose isn't going to want any of this Motobilt stuff coming off his laser machine looking like cheese factory. I feel like I put a lot of effort into it, and you guys helped make it. Thanks.I would recommend either not cutting out these windows, or at least making them an X or other triagular based form. The amount you have weakened it is exponentially greater than the weight you are saving.

View attachment 332828

I’m no train driver, but you are missing some material where the amount of greatest load is cantilevered. I foresee bent control arms in the future.

Revision needed or push the rear LCA rear some more to eliminate the cantilevered load.

Your material need in that plane stops at the first shock mount. This combined with HAZ from assembly is a poor recipe.

That would be a major improvement. If it were me, I'd also move the windows away from the weld joints a good bit more. Maybe do 2 larger windows instead of 4. But I also don't think the weight savings is worth it in that area and would just leave it solid.Maybe I'll replace the columns in those windows with hollow rotated squares.

A Milwaukee M18 fuel compact impact with 12.0 battery could probably do it 500 times.Shoot, crucial things I have to go over. I almost forgot to integrate a hole or two in the control arm to lift a flat tire off the ground with a jack. This particular screw jack requires the use of 3/4 inch socket.

Maybe there are some mechanics on here that can recommend the right battery powered impact gun to outfit on the car. I'll have to plan on mounting this jack, and the impact on the car so the driver will be prepared to pull off the track and change a flat tire.

I'm not sure if I like the fact that the nut on this Jack requires a 3/4 inch socket. I'd like to use the same socket to change the wheel and operate the screw Jack. Maybe I can take it apart and modify the screw to make it use a larger hex.

I wonder how many tires one of those nice 1/2 inch battery impacts can change on one charge and jack the car up a number of times.

View attachment 332862

The bent weld tab you're referring to with nothing under it is axle recess.

Nope, not that one. The one in front of that.

That piece has the sole purpose of keeping the floor from acquiring a huge dent in the bottom of it, but it doubles as reinforcement for the front.

Nope, not that one. The one in front of that.

Also, you should put a radius at the "V" between the two inboard legs, even if it's just a generous fillet in the top and bottom skin and not the bent plate pieces.. Else, the skins are going to crack there.

Okay, makes sense. I'd still move the weld tabs to the left and right of the unsupported area on top. If you're going to have a weld tab, make it do work. Else you're just adding a buckling point. Remember that if you're stressing the skin of the control arm to make a torsion box, you don't want to add unnecessary features that could add local stress.

You're doing a cool design, it just needs to be thought through a little more.

A Milwaukee M18 fuel compact impact with 12.0 battery could probably do it 500 times.

So I feel like what your trying to get across is I need to get rid of these centrally stationed weld tabs, and make some on the east and west sides of it. Then I need to make sure I gusset both interlocking intersections.

View attachment 332896

Seems overkill. How much torque is required for this jack?

The highlighted one closest to the viewer is the one that needs to be tweaked. If you visualize the load paths based on the pockets in the plate, putting a weld tab on either side (instead of the middle) makes sense. Think about it like the nodes of a truss.

The other one you have highlighted looks fine. It's sort-of the inverted version of the first one, so a tab in the middle makes sense for load paths, because the tab is at the node.

I don't want to hyper-focus on that one small detail, it was just something that jumped out at me.

Seems overkill. How much torque is required for this jack?

Now onto introducing a tube hole for the jack, and forming the gussets that we're after to ensure we knock out this twisting concern.

Now onto introducing a tube hole for the jack, and forming the gussets that we're after to ensure we knock out this twisting concern.