Van-go

Not an old man

- Joined

- Dec 11, 2014

- Location

- Greensboro

Before I took a trip to Harlan I wanted to get my Winch working right. It was very intermittent if it would work at all.

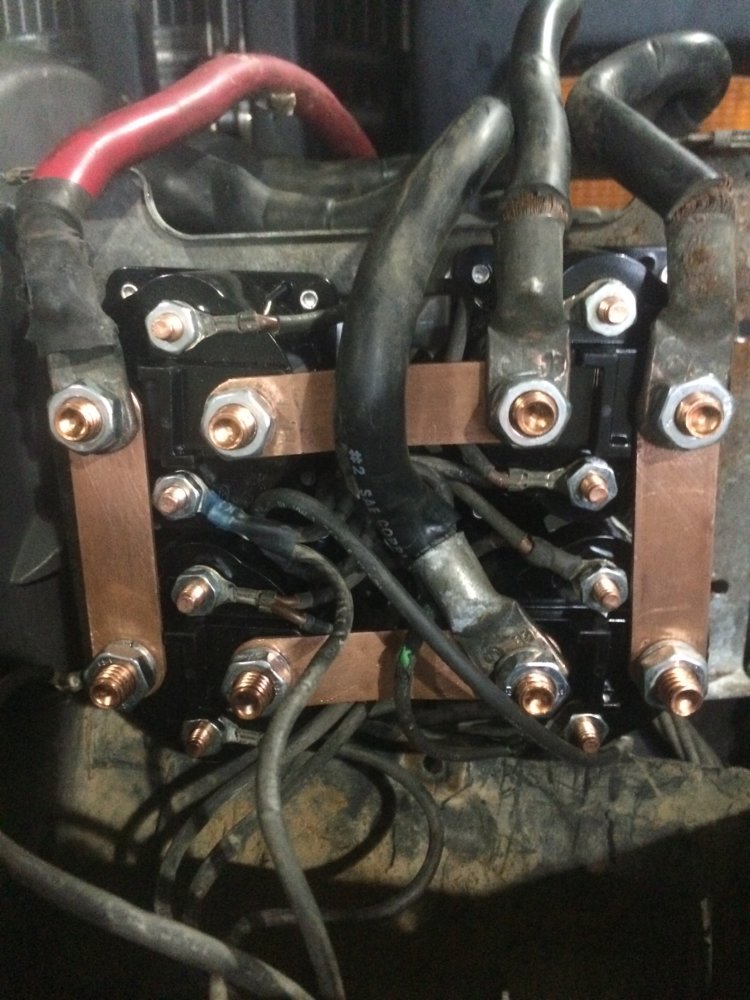

I replaced all 4 Solenoids and installed an Optima battery to help get the m12000 going...

I cleaned everything up and replaced all solenoids. It worked great.... for one pull at Harlan.

I took it apart at camp the next day and 3 of the 4 of the solenoids had gone bad.

I guess I learned my lesson with DB Electrical solenoids...

I threw 2 of the old warn ones in and it reels in now, but you have to free spool it out.

I am trying to trade the winch for a lighter one, preferably with the Albright or Warn Contactor style solenoid.

It's something like $240 for a contactor pack and new remote from Warn... Trying to avoid that.

I replaced all 4 Solenoids and installed an Optima battery to help get the m12000 going...

I cleaned everything up and replaced all solenoids. It worked great.... for one pull at Harlan.

I took it apart at camp the next day and 3 of the 4 of the solenoids had gone bad.

I guess I learned my lesson with DB Electrical solenoids...

I threw 2 of the old warn ones in and it reels in now, but you have to free spool it out.

I am trying to trade the winch for a lighter one, preferably with the Albright or Warn Contactor style solenoid.

It's something like $240 for a contactor pack and new remote from Warn... Trying to avoid that.

and the red jeep's motor blew later that night... that was a long tow out and back to camp.

and the red jeep's motor blew later that night... that was a long tow out and back to camp.