Tacoma747

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Winston-Salem

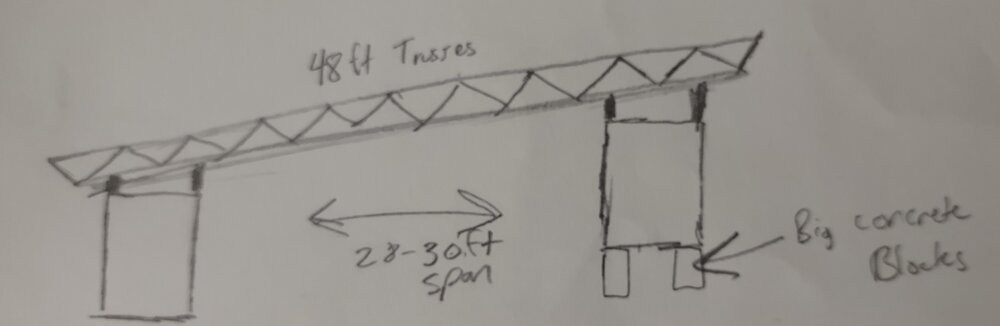

So I am no engineer, and this will not be permitted so it doesn't really need to be engineered, but I am putting two 40' containers at my land with a roof over the top of them. I found some 2' tall 48' long steel trusses. For you guys that might be structural engineers, does this look like it would be sufficient? I will have to weld pockets for the purlins to the tops of the trusses, that or attach the roofing metal horizontally and don't have purlins, but that obviously makes rain/snow not come off as easily. The drawing is obviously not to scale, but the upper container will likely sit 5+ feet higher than the bottom container. The span between the containers will be 28-30 feet, and I am hoping to do a clear span. The containers will be anchored to 2'x2'x6' concrete blocks at each corner. They are 40' containers and I can get 6 trusses, so they would be spaced every 8ft.

Thanks for any advice.

Thanks for any advice.