GarageBuild

New Member

- Joined

- Feb 6, 2018

- Location

- Dallas TX

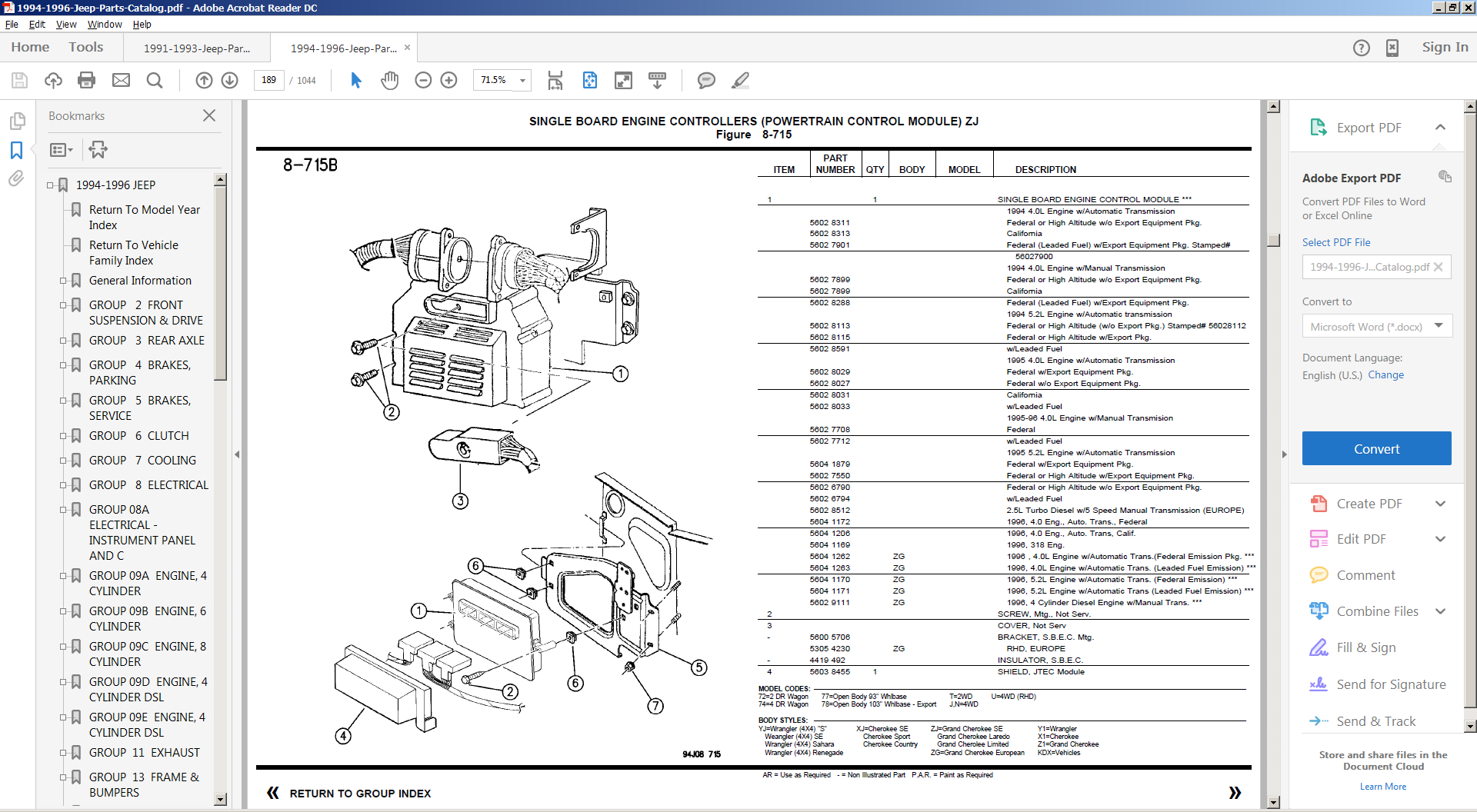

That part is very easy. There's wiring diagrams online. The hard part is the coding experience (which I somewhat lack). Would love to have another hand on the project! We're very close to getting the stock ECU to flash. Late 94 and 95's are flashable. Like A_kelley mentions, if the case has screws, it is not flashable, if it has snaps, it is.

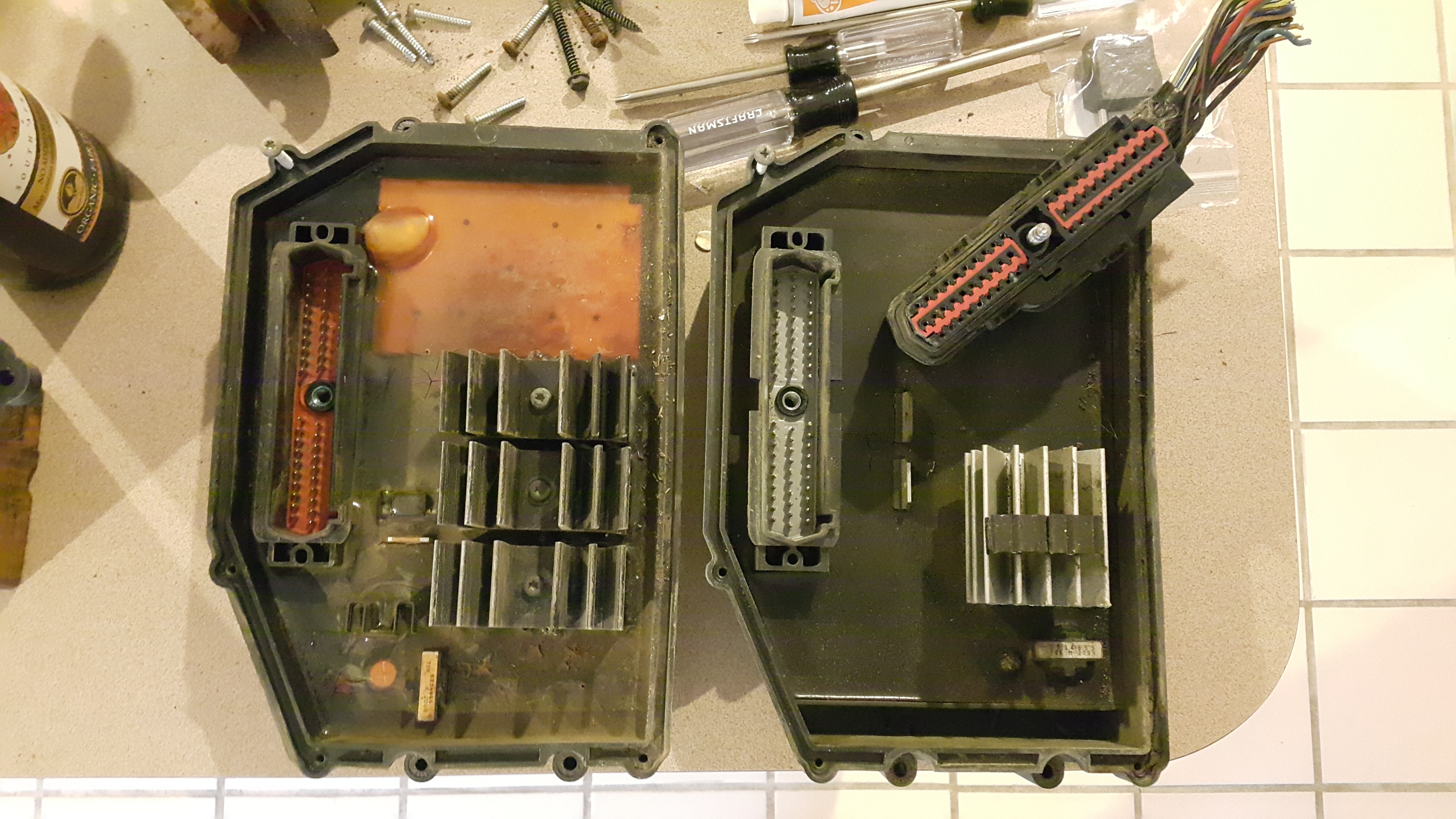

I went to two pick-n-pull yards. Including the ones I have, I now have 5 ECUs:

1. (pictured left.) Mopar R6026790 "remanufactured" PCM for 1995. (It has torx screws.)

2. (pictured right.) 56028113 Federal or High Altitude (w/o Export Pkg.) Stamped# 56028112 for 1994 (this looks like 56028011 on the inside)

3. Original 56028011 for my V8 1993 (not installed)

4. 56028026 for a 1995 4.0 (got this just for kicks)

5. mopar performance ECU P5249518 (installed in vehicle)

Which are useful for boosting my V8?

Which are not compatible 95 vs 93?

Which can I dump the flash memory from?

Is the 95 4.0 ECU useful for reflashing as a V8 or is the board physically different?

Great insight as always!

Great insight as always!