You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JKUR, My last Build...

- Thread starter 89wrangler

- Start date

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

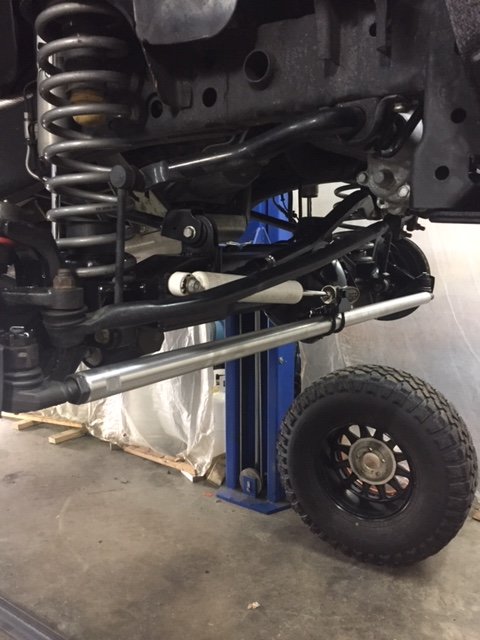

Little update.

Rear gears installed

Front going in

Rock crusher covers and rear tubes welded up

One tie rod stuff waiting on “another” aluminum tie rod

With 37’s and method beadlocks. Going to change ring color.

Rear gears installed

Front going in

Rock crusher covers and rear tubes welded up

One tie rod stuff waiting on “another” aluminum tie rod

With 37’s and method beadlocks. Going to change ring color.

- Joined

- Mar 20, 2005

- Location

- Morganton NC

Looking good Steve!

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

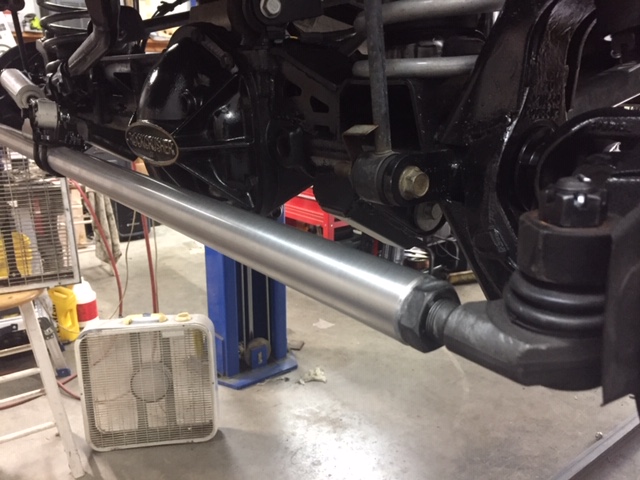

Got a little more done yesterday. Install the 1 ton TRE's and 1 1/2 alum. tie rod.

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

Had some parts show up today I ordered yesterday. What a sweet deal! So why not install them!

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

Got around to changing the ring color this weekend and swapped out the wheel sensors as well. The original ones in the wheels would not communicate with my system. What a Pain In The Ass to change those little bastards working blind through a gap in tire barely the size of your hand! On top of that, smashed finger, bruised wrist, snapped 6 grade 8 bolts torquing to 20 ft lbs. The job required way more Gin than than I was prepared for.

rings removed

Now to try and get that wheel sensor out. My first method failed me as the crow bar holding tire apart would slip and the tire would smash the shit out of whatever was in the gap. Having right wrist clamped in the tire while trying to re-position crow bar with left hand to get it out, with what felt like someone standing on it, is no fun. Finally got some wood blocks.

spare. not sure why the grade 8 bolts were snapping off.

finished product

Got the aluminum tie rod and parts for over the knuckle on the way as well as well as the rear control arm skids from Barnes

rings removed

Now to try and get that wheel sensor out. My first method failed me as the crow bar holding tire apart would slip and the tire would smash the shit out of whatever was in the gap. Having right wrist clamped in the tire while trying to re-position crow bar with left hand to get it out, with what felt like someone standing on it, is no fun. Finally got some wood blocks.

spare. not sure why the grade 8 bolts were snapping off.

finished product

Got the aluminum tie rod and parts for over the knuckle on the way as well as well as the rear control arm skids from Barnes

Last edited:

mcutler

Well-Known Member

- Joined

- Apr 17, 2010

- Location

- mt.airy nc

Looking good Steve, be nice having you back in the trenches

Sent from my SM-G892A using Tapatalk

Sent from my SM-G892A using Tapatalk

mcutler

Well-Known Member

- Joined

- Apr 17, 2010

- Location

- mt.airy nc

Btw, I've got two used 37 nitto trail grapplers, about 80 % if you need some to have around.

Sent from my SM-G892A using Tapatalk

Sent from my SM-G892A using Tapatalk

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

Got rear lower control arm skids welded on this past weekend. Hope to install the rear bumper/tire carrier and aluminum drag link this weekend.

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

Got the rear bumper, tire carrier installed and back up camera transferred over to the new set up. I forgot to put my thumb over the license plate so I nothing terrible happens.

Also got the aluminum drag ling and one ton tre's installed

Also got the aluminum drag ling and one ton tre's installed

- Joined

- Mar 20, 2005

- Location

- Morganton NC

Looks good Steve!

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

Tube doors touched up

1/2 Door skins painted

Still have to wet sand and buff.

1/2 Door skins painted

Still have to wet sand and buff.

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

Got the 1/2 doors done in time for the Dixie Run.Worked out great. Mirrors showed up 10 minutes before we left. At $30 a pair, good for trail, suck for highway driving though. gonna have to see if i can tighten them up.

.

.

jyaks

Too many kids for a TJ

- Joined

- Sep 3, 2008

- Location

- Archer Lodge

Those half doors look great

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

The next chapter.

Shock porn ( for me at least)

Shock porn ( for me at least)

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

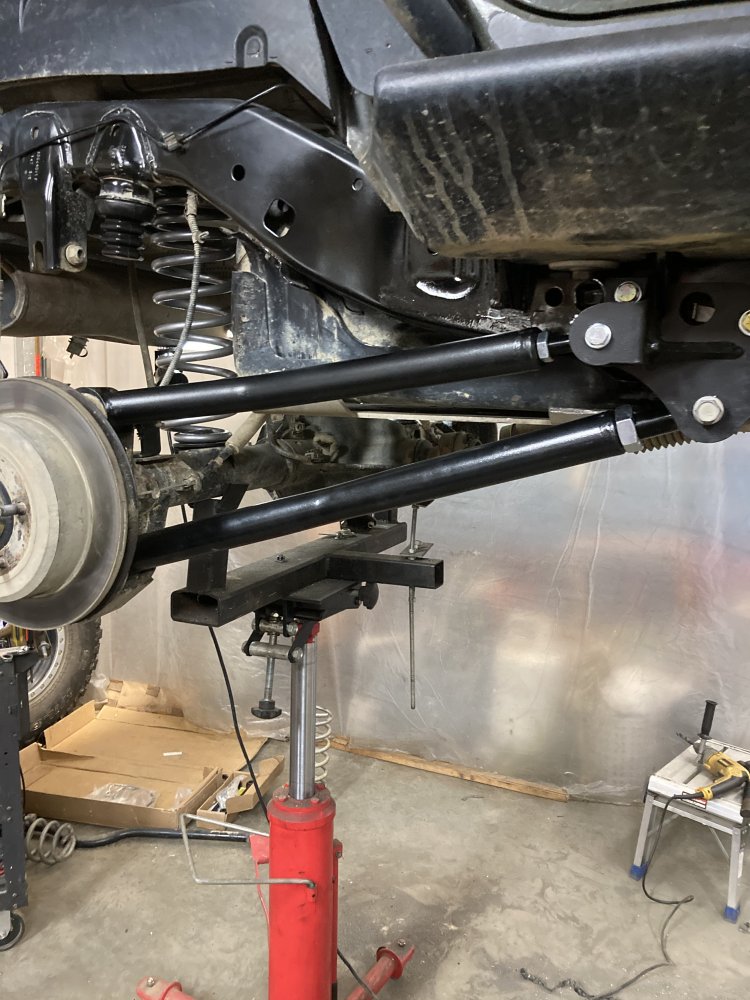

Time to add some long arm stuff to the mix working on the front. Spent 2 hours trying to skid plates off which should have been a 15 minute job. Damn those counter sunk hex head bolts that will not be returning to service this go around

Anyway, the goods for front

removed track bar, shocks drive shaft, springs, bump stops

The next no fun at all part is removing the stock control arm brackets

This is where my little injury happened. Was using Saws all on upper bracket and everything was going real smooth, was almost all the way through when the blade hit the bracket, kicked back like a mule. Faster than the blink of an eye, the saw slammed into the corner of the 1/4 steel frame holding the front axle. Oh and my hand happen to be holding that saw, which ended with me driving to the urgent care to get stitched up.

So next day I am back at it with 1 1/2 hands, get brackets cut off and ground welds off of frame and painted

Anyway, the goods for front

removed track bar, shocks drive shaft, springs, bump stops

The next no fun at all part is removing the stock control arm brackets

This is where my little injury happened. Was using Saws all on upper bracket and everything was going real smooth, was almost all the way through when the blade hit the bracket, kicked back like a mule. Faster than the blink of an eye, the saw slammed into the corner of the 1/4 steel frame holding the front axle. Oh and my hand happen to be holding that saw, which ended with me driving to the urgent care to get stitched up.

So next day I am back at it with 1 1/2 hands, get brackets cut off and ground welds off of frame and painted

Last edited:

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

Had to move the exhaust back about 1 3/4 to make sure cross over pipe would clear front drive shaft.

Then installed the new control arm brackets and upper and lower control arms

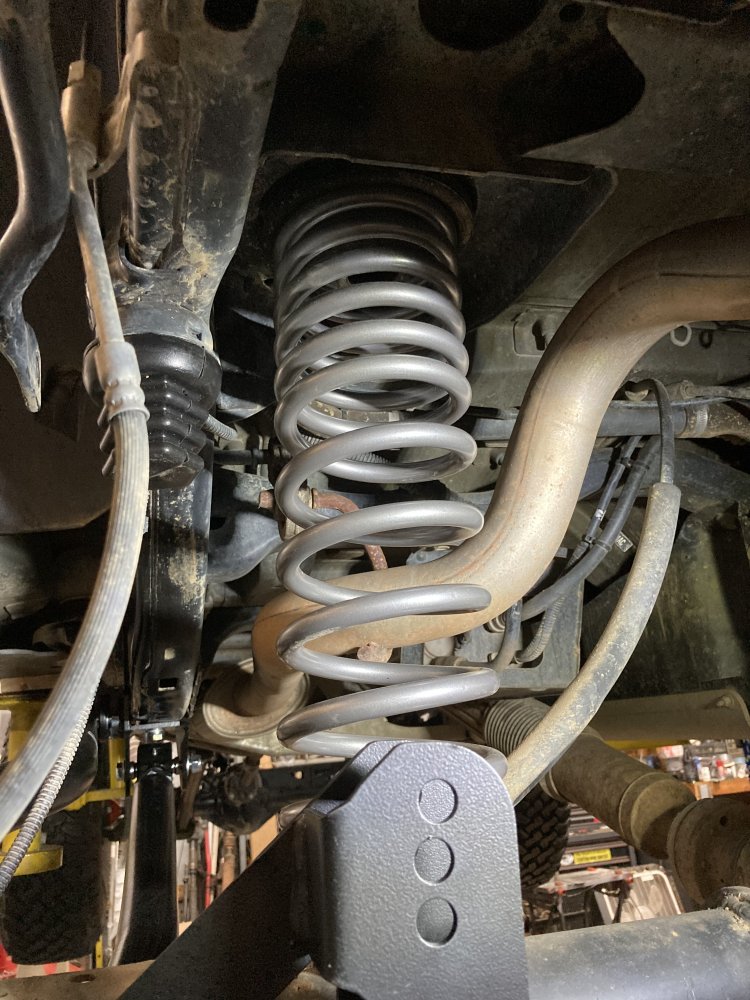

next was the metalcloak bump stops, coil springs and ss extended brake lines and shocks

Hopefully more tomorrow

Then installed the new control arm brackets and upper and lower control arms

next was the metalcloak bump stops, coil springs and ss extended brake lines and shocks

Hopefully more tomorrow

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

Got a little bit more done this evening started with the inner fenders. Must say they fit really nice

hooked up drive shaft and got sway bar links ready to hook up and snugged up control arm bolts. Happy with the extra travel.

Starting on rear tomorrow. Should go easier than the front....I hope

hooked up drive shaft and got sway bar links ready to hook up and snugged up control arm bolts. Happy with the extra travel.

Starting on rear tomorrow. Should go easier than the front....I hope

- Joined

- Mar 20, 2005

- Location

- Hendersonville, NC

I have some classy stickers you need on that tool box.

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

I will say that these parts do not play well with a full Artec skid plate system. Having to make modifications to make it all work together.

rear parts

this means cutting of more brackets. Being extra careful I might add.

then have to cut and notch skid plate in order the fit brackets

Finally some arms and coil springs

along with some metalcloak bumps on the rear

shock comparison of old vs new

SS brake lines and shocks installed

Once it was on the ground, had to adjust the rear pinon angle some, adjusted the track bars, torqued all the control arm bolts and had to center the steering wheel back up.

The test drive went exceptionally well. Ride was better and handling was even better than it was. Very pleased.

next will be installing the rear cromo axles.

rear parts

this means cutting of more brackets. Being extra careful I might add.

then have to cut and notch skid plate in order the fit brackets

Finally some arms and coil springs

along with some metalcloak bumps on the rear

shock comparison of old vs new

SS brake lines and shocks installed

Once it was on the ground, had to adjust the rear pinon angle some, adjusted the track bars, torqued all the control arm bolts and had to center the steering wheel back up.

The test drive went exceptionally well. Ride was better and handling was even better than it was. Very pleased.

next will be installing the rear cromo axles.

Last edited:

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

Something finally went easy. Installed new backing plate seals and bearings on the Cromo shafts, removed stock ones and put in new ones. About an hour and done. Went ahead and drained diffs an going to dump in some new tomorrow. Then reinstall the skids. Next will be the PSC hydro assist. Not really looking forward to that either..  I think old age is really catching up with me haha!

I think old age is really catching up with me haha!

Out with the stock shafts. ( will keep for spares)

Old and new

Spares

all done

I think old age is really catching up with me haha!

I think old age is really catching up with me haha!Out with the stock shafts. ( will keep for spares)

Old and new

Spares

all done

- Joined

- Mar 20, 2005

- Location

- Morganton NC

looking good Steve, next year, one tons LOL

89wrangler

Not a new member

- Joined

- Oct 22, 2005

- Location

- Bostic,NC

Haha! That ain‘t gonna happen unless I play the lottery and win. And if that is the case, someone else will be installing them.looking good Steve, next year, one tons LOL