Mac5005

Well-Known Member

- Joined

- Oct 19, 2005

- Location

- Rocky Mount

what is your opinion of the Aspect units?? I am sorta on the fence. We use them for Stick welding as well. Definitely different..... I am a old school transformer welder except for all these bells and whistles that can make everyone look like a pro when applied correctly.

I would rather have my old squarewave 350 transformer machine for such a smooth arc on dc- but choosing between the inverter stuff,

I definitely prefer the aspect over the dynasty. Any day, easy choice.

Biggest things I’ve noticed is that the aspect high freq start is HOTTTT compared to older stuff. So tiny low amp starts are tedious.

As far as the dynasty350s we have, no two machines weld the same, despite having identical settings and setups on them. I’d hate to be buying one machine, and get a “bad” one. Several issues with them inside of 3 years that required major service.

All the aspects weld identical. I definitely prefer them. I like their DC- arc much better than the dynasty, but still 2nd to a transformer machine.

Ac, I like the aspect better than the dynasty.

I actually like the everlast AC arc better than the dynasty also.

And I don’t feel like trying to find/access the dynasty hidden settings. Screw that noise.

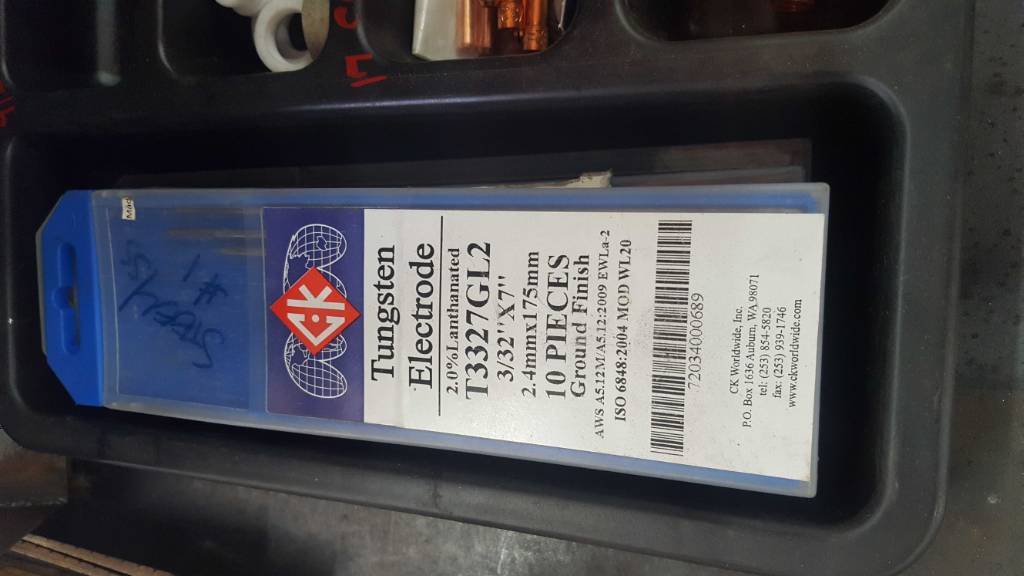

I hate all the Uber small collets and collet bodies and cups though. The threads are too small they just don’t last, I miss the larger size stuff for 90% of the work. The last 10% requires the small torch with a stubby stem cap for something silly.

Too often the collet body/stem threads are junk before their time.

I do like the quick connect fittings on the aspect over the Miller standard threaded stuff.