I started with some CAD work, but didn't get much farther than that. Big thanks to Ross @Hudson1 for being willing to 3D print the parts for me to try.

Biggest challenge from what i recall was fitting a stub and brakes. The 99-04 bearings would be easier to use, and could likely work by redrilling the knuckle and using the SD stubs. I havent messed with brakes, but honestly think that would be easy once the rest is solved.

I was running under the assumption of being able to use the stub shaft for the kingpin axle, and using factory length components so that spares are easy/cheaper. The 05+ stub is the one I wanted, but couldnt find the dimensions or drawing of one to try. Also, not sure how much value the 05+ stub is without the 1550 ujoint. I believe it would require machining of the knuckle, making them weaker, and wouldnt leave much options for brakes. If someone can get me the dimensions, or has a shaft they are willing to send me, I would be glad to give it another round.

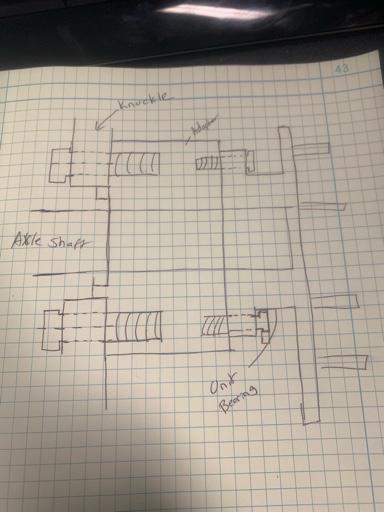

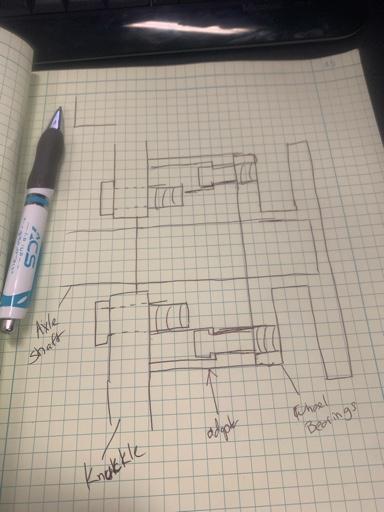

Here are some pics:

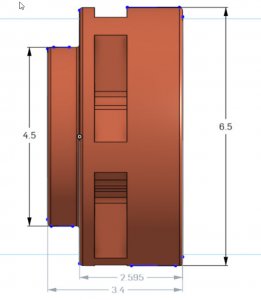

This 1st set was what i ended with, to keep the WMS more narrow, but requires a custom slug or stub also.

Here is the 1 version, that would didn't need the custom stub/slug: You can see how much longer it is.

Here is the version for the 99-04:

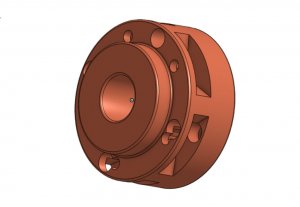

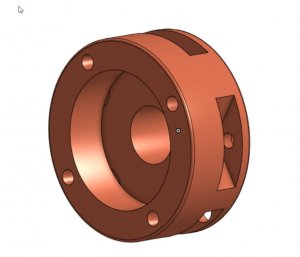

Not that most here would find it interesting, but I also drew up an adapter to bolt a 05+ bearing on the end of a 9" or any axle using a Set-20 bearing.

At the end of the day, the adapter would likely cost more to machine than anyone would want to pay. Pricing a blank to cut it from was more than i wanted to spend, before the lathe work. I think someone could make it multiple parts that weld together, for cheaper, I just haven't had the time to investigate. Once I knew the dimensions of the different components, the CAD work wasn't challenging.

Also, if you swap your kingpin axle to slip-on rotors, removing the hub as an assembly becomes almost as easy as a unit bearing.