Buffy

Well-Known Member

- Joined

- Jan 31, 2010

- Location

- Burlington, NC

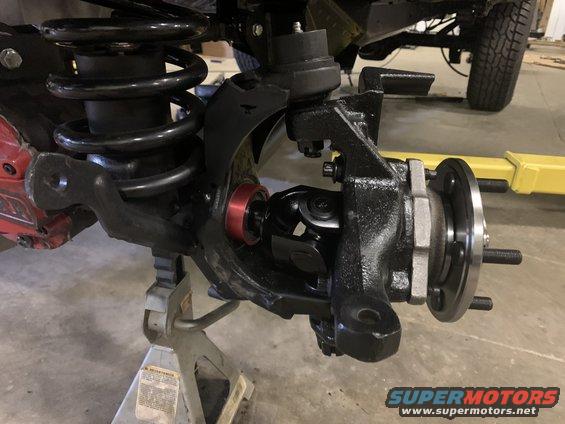

One of the upper control arm bushings needed replacing so I decided to "church it up" as Mr. Treadway says and sprung for the Iron Rock upper control arm bushings. They aren't kidding when they say they are precision machined. Thee things look like jewelry, for your axle. A bit of a pain to get them installed and assembled. Word of advice, if you plan on getting these spring for their install tool. I don't know how you could install them without it and not damage the machined body.

You have to install the body first and then assemble the internals afterwards. Here are all the pieces.

Here is a view of the two sides ready to be pressed in. Passenger side was a snap driver side was a fight!

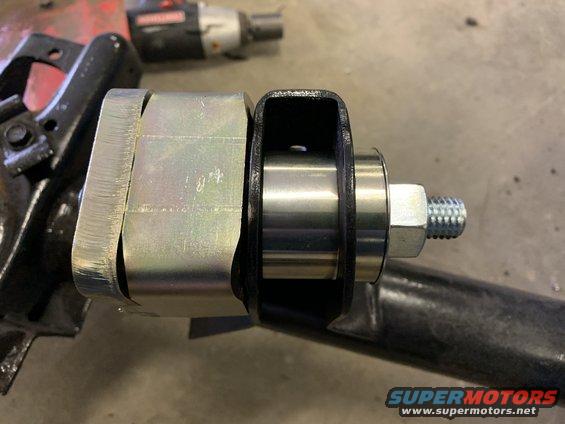

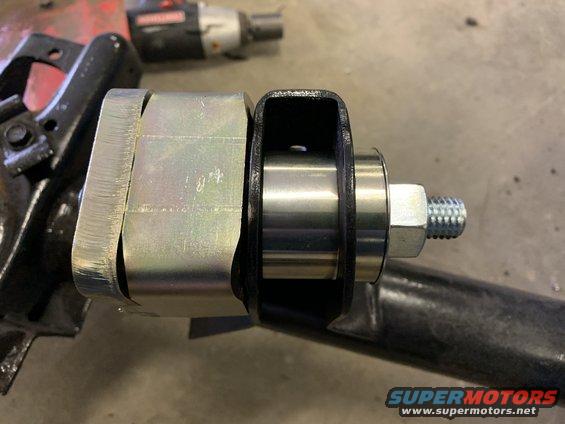

All in and assembled. There are 8 very fine threaded and tiny screws that hold everything together. Then you have to torque them all to 20 inch pounds. I was sweating bullets trying to get to that torque setting. I was expecting the screws to snap or stripping the heads off but alas I made!!

Overall I am impressed with the quality of these bushings. If they perform half as good as they look I am set.

You have to install the body first and then assemble the internals afterwards. Here are all the pieces.

Here is a view of the two sides ready to be pressed in. Passenger side was a snap driver side was a fight!

All in and assembled. There are 8 very fine threaded and tiny screws that hold everything together. Then you have to torque them all to 20 inch pounds. I was sweating bullets trying to get to that torque setting. I was expecting the screws to snap or stripping the heads off but alas I made!!

Overall I am impressed with the quality of these bushings. If they perform half as good as they look I am set.