StretchASU

Well-Known Member

- Joined

- Oct 17, 2006

- Location

- Creedmoor, NC/Claudville, VA

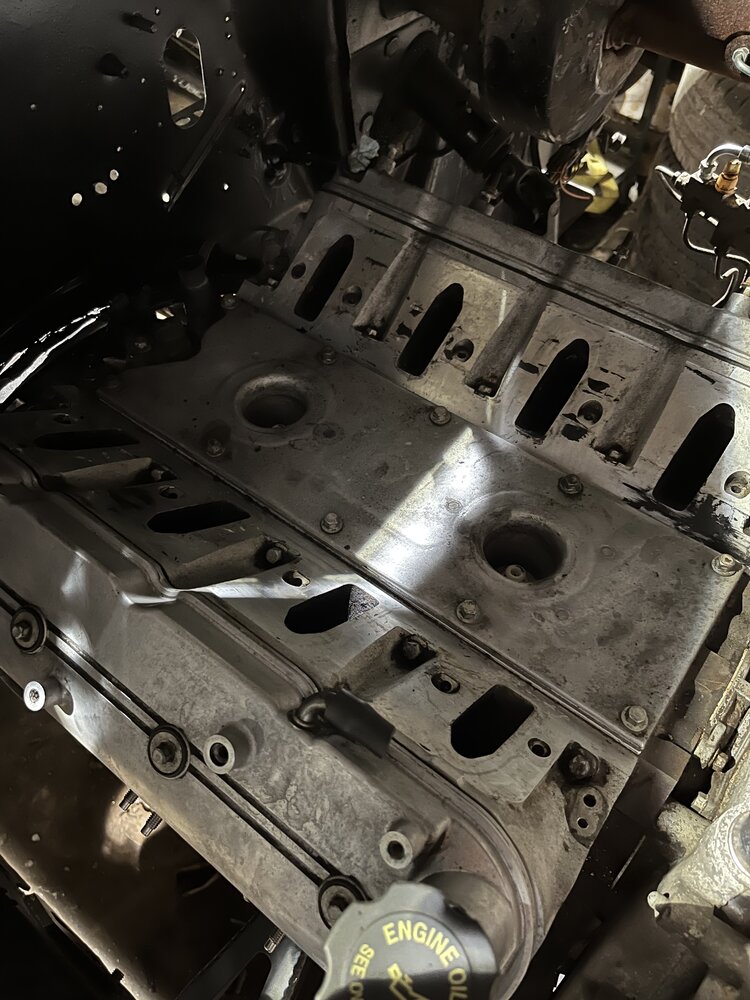

Got the chance to work in the shop tonight since I’m working nearby today and tomorrow. I still need a tank of gas for the welder so I started putting the top side of the engine back together now that I don’t need to pull it again.

The plug ends of the knock sensors had broken when I took things apart and the harness was pretty crusty. Replaced those, their harness and seals for the valley cover. The steam port lines were pretty rough too so I decided to try out the Motion Raceworks kit that I had sitting in the toolbox for the wife’s Camaro.

The plug ends of the knock sensors had broken when I took things apart and the harness was pretty crusty. Replaced those, their harness and seals for the valley cover. The steam port lines were pretty rough too so I decided to try out the Motion Raceworks kit that I had sitting in the toolbox for the wife’s Camaro.