RubiconBear

Well-Known Member

- Joined

- May 31, 2012

I don't mind the tire noises. The tire wear is kind of a deterrent, but the tires were put on in May, so not many miles. Will I see a ton of wear in 3-5K in a year though?

Ok, I think I will move away from the Track Lok. Now, True Trac ($$$) or Spool ($)? It will be driven 3-5K miles a year. Some in the winter, but not too much. 99 tj 3-3.5" unknown lift 33-12.50 MTs. Thoughts? I know the spool is a little crazy, but dang it's cheap. I know selectable tends to be the best choice, but too much $$$.

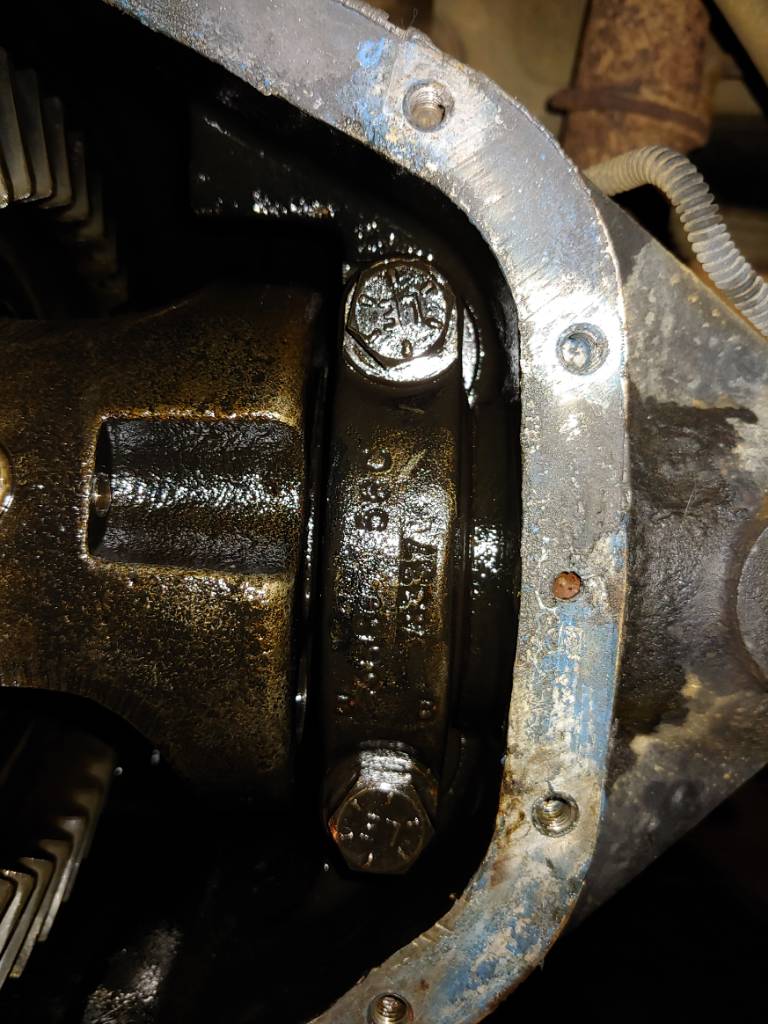

It'll be an S also, just turned 90*Oh yeah, looking at the last pics I posted I can see the "S" on the driver side. I can almost make something out on the passenger side. I'll look when I clean it off to see. Pretty cool.

Sent from my LM-G710VM using Tapatalk

I'm guessing the vertical "S" should match up with the other vertical "S" right? I just realized, while test fitting the carrier, that they were switched (vertical with horizontal). As stated earlier, the PO had been in the rear diff before.It'll be an S also, just turned 90*