- Joined

- Mar 20, 2005

- Location

- Morganton NC

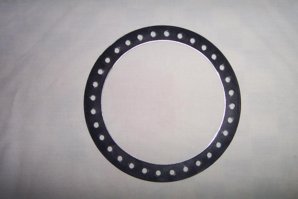

A friend of mine and I are thinking about going into the 4X4 production of different things, one of them being weld on bead lock kits.

A few questions:

I assume most kits are drilled for the 32 holes using a drill index. Any idea of where to get one, and what would be the cost. It would need to be able to go anywhere from 16" to 21" for the variety of sizes.

Again, I am assuming that you do need a indexing head to be able to make all of the rings interchangeable.

2. What is most preferred

a. drilled holes?

b. tapered holes for flush mounted Allen bolts?

c. Nutserts or use nylock nuts?

d. Would you prefer bare steel for outer ring, or would you prefer it to

be powder coated?

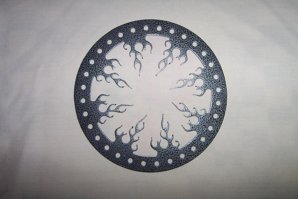

3. We are open to ideas of any and all items you would like in the pre-fabed dept. Weld on tabs gussets and so on from plain Jane to fancy spider webs and such

Thanks

Chip

A few questions:

I assume most kits are drilled for the 32 holes using a drill index. Any idea of where to get one, and what would be the cost. It would need to be able to go anywhere from 16" to 21" for the variety of sizes.

Again, I am assuming that you do need a indexing head to be able to make all of the rings interchangeable.

2. What is most preferred

a. drilled holes?

b. tapered holes for flush mounted Allen bolts?

c. Nutserts or use nylock nuts?

d. Would you prefer bare steel for outer ring, or would you prefer it to

be powder coated?

3. We are open to ideas of any and all items you would like in the pre-fabed dept. Weld on tabs gussets and so on from plain Jane to fancy spider webs and such

Thanks

Chip