- Joined

- Mar 20, 2005

- Location

- Morganton NC

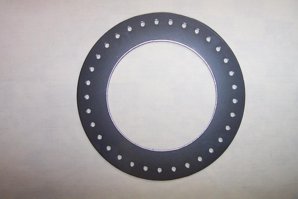

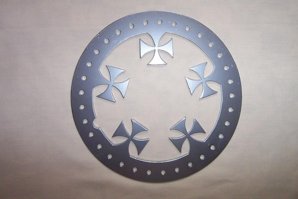

Aluminum? in a 17" 32bolt.

A possibility. As of now just working with steel. Will have to get some aluminum and see what we can work out. The biggest issue I have seen with the aluminum is that because of the lower melt, the slag tends to burn back into the work peice. This may be preventable with adjustments. Not sure. When I have an answer, I will let you know

Thanks

(not that Rich is stoopid, just that there's no Thumbs up smilie).

(not that Rich is stoopid, just that there's no Thumbs up smilie).