How about a 3d Printed functional hand?

Seniors at the local science and math academy HS do a capstone project. The young lady I'm mentoring this year is making a hand with force feedback on the fingers to adapt grip strength to different objects... then control via EMG.

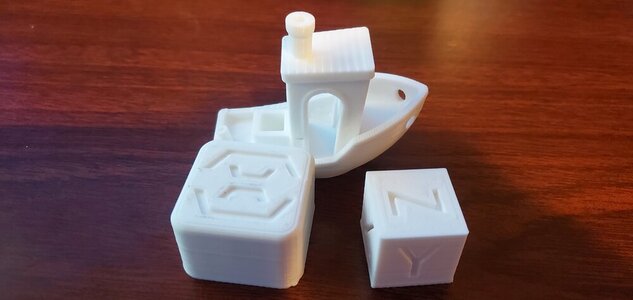

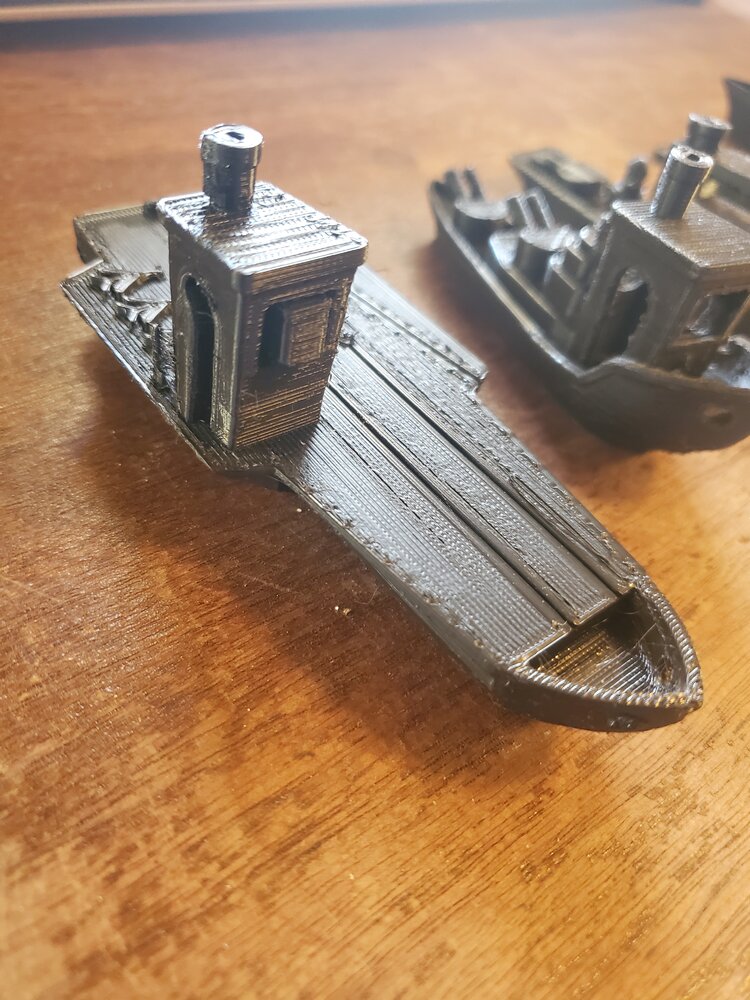

This is the hand structure she designed, I printed.

View attachment 368748

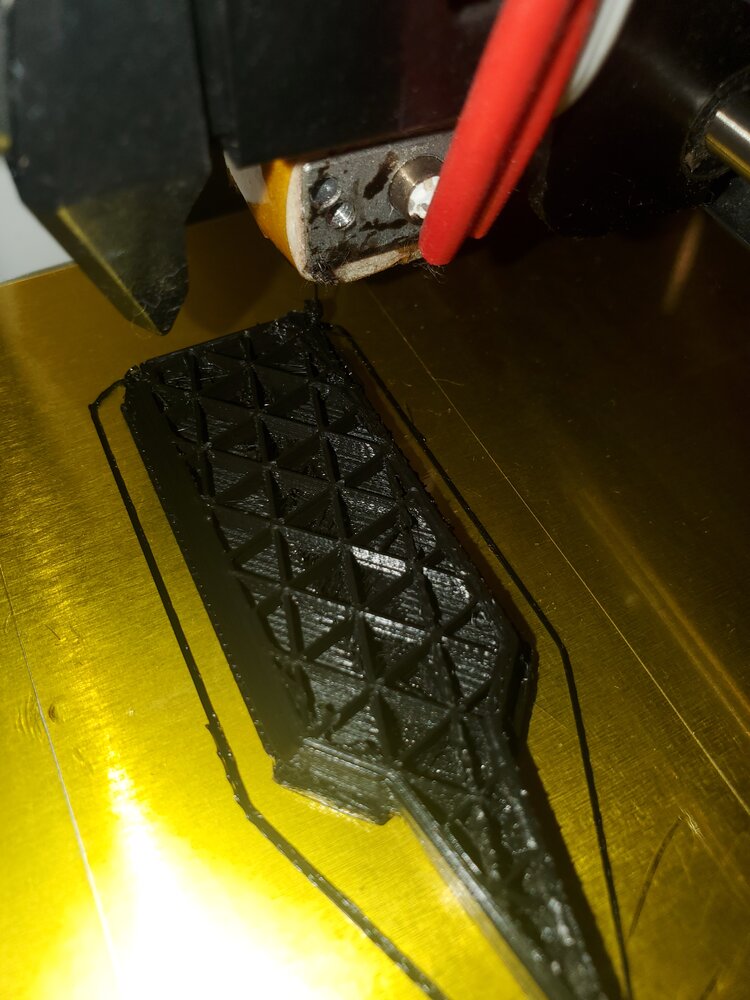

The black is TPU so it's flexible, white is ABS. All one print with a dual nozzle machine. The stringy parts on the thumb are supports to be cut off.

Strings will run through the fingers to servos in the white "wrist" to pull them like tendons, bend at the thin joints.

I'll post more as it develops.

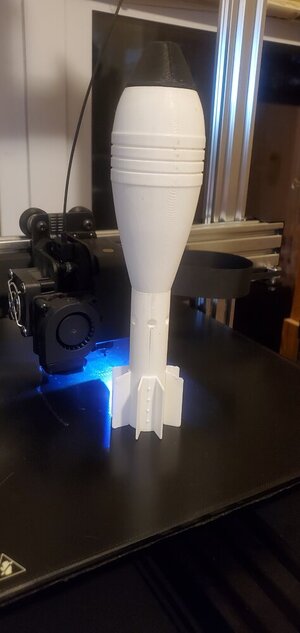

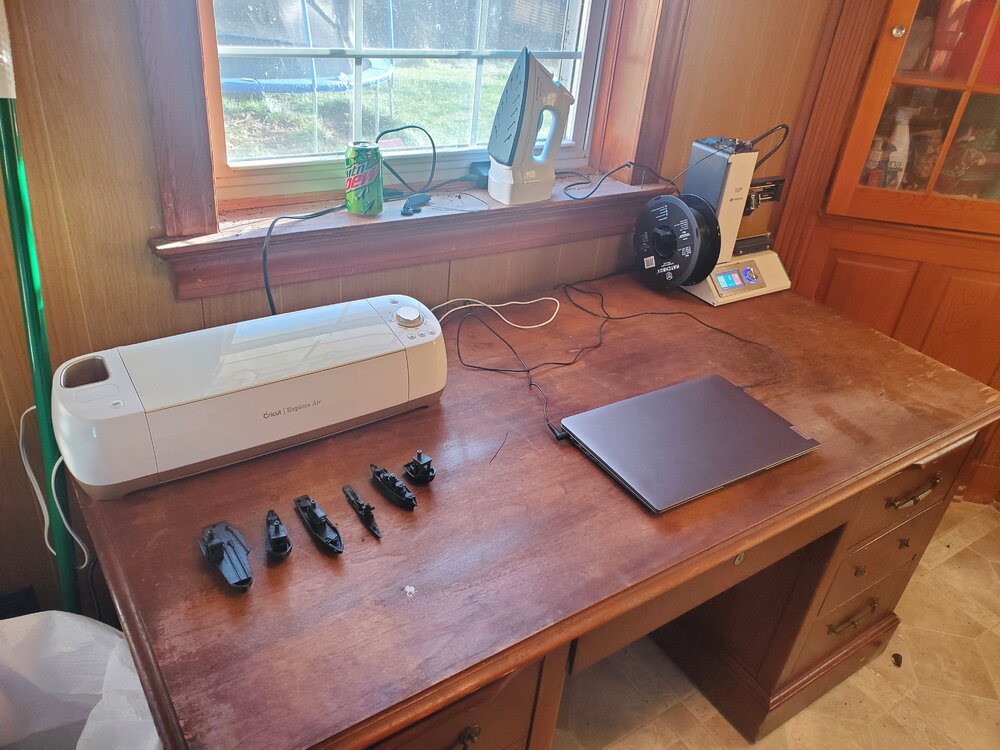

. It technically belongs to a coworker who went on a year assignment to London, he left it w/ us so it has become my son's project printer (see my next post...). He immediately added a BL touch to it for auto-leveling.

. It technically belongs to a coworker who went on a year assignment to London, he left it w/ us so it has become my son's project printer (see my next post...). He immediately added a BL touch to it for auto-leveling.