I’ve been meaning to actually make a build thread for this junk for a while so here it goes. I’m pretty bad about remembering to take pics as I’m working so I’m sure I’ll miss some stuff.

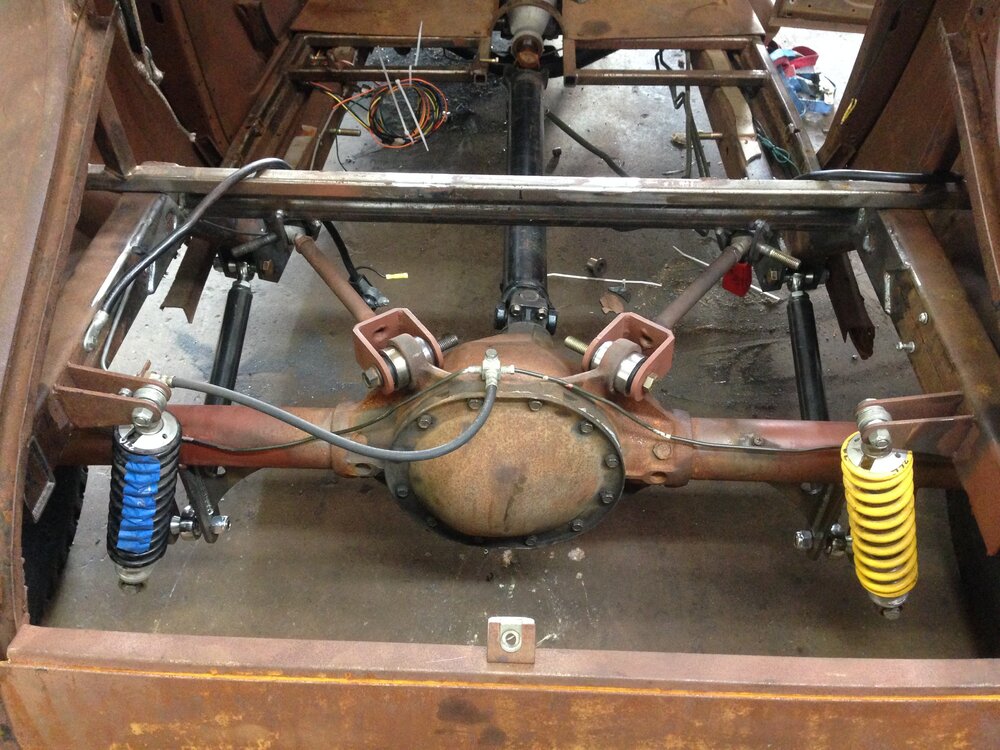

So here goes the backstory on this thing. I originally bought a 1927 Model T coupe built as a hot rod when I still lived in Texas. 402 BBC, manual VB powerglide, weird BOP 12 bolt. It was almost finished when I bought it. I finished it on the roof level of the parking garage for my apartment. It really wasn’t on the road very long before I got T-boned in traffic. Not a fun day. I ended up buying it back from the insurance company and fixing it. Fast forward a bit to having moved to Albemarle and I finished the new rear suspension the night before trading it for a tube chassis buggy.

So here goes the backstory on this thing. I originally bought a 1927 Model T coupe built as a hot rod when I still lived in Texas. 402 BBC, manual VB powerglide, weird BOP 12 bolt. It was almost finished when I bought it. I finished it on the roof level of the parking garage for my apartment. It really wasn’t on the road very long before I got T-boned in traffic. Not a fun day. I ended up buying it back from the insurance company and fixing it. Fast forward a bit to having moved to Albemarle and I finished the new rear suspension the night before trading it for a tube chassis buggy.