BUCKEYE PERFORMANCE INC.

BUCKEYE PERFORMANCE INC.

- Joined

- Dec 3, 2006

- Location

- swannanoa

seen your update and thought you installed rear spring retainers

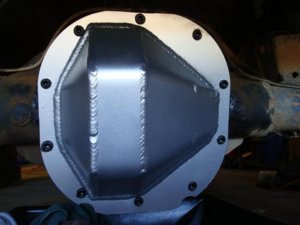

Cover is painted and ready to mount tomorrow

Let me know what you think, Just couldn't force my self to paint it black, I needed a little

View attachment 30624

View attachment 30625

www.mudprometalworks.com

or are they just going to stay pretty on the work bench? lolare u gonna use some grade 8 bolts in those ta-ta,s

Looks good Mike and i like the ghetto fab tool i think its a keeper

i see you found something to do with your short vacation.