You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chainsaws

- Thread starter Ron

- Start date

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

I've never had a single one come loose. How do you tighten em? (hint: "using my fingers" is NOT the right answerAnyone had a problem losing bar nuts on a sthil? Often? Yes it gets cleaned.

)

)- Joined

- Mar 24, 2005

- Location

- Stanley, NC

Is there junk stuck to the cover preventing it from seating all the way? Same nut (front or back) every time?

- Joined

- Apr 16, 2005

- Location

- Sharon, SC

It's happened to me twice this year. I've got to where I tighten it every time I use it just in case

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

How old are yalls saws? My 30 year old nuts work just fine and have yet to fall off

Tacoma747

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Winston-Salem

How old are yalls saws? My 30 year old nuts work just fine and have yet to fall off

Wait, what are we talking about here again?

Dirt Mcgert

Well-Known Member

- Joined

- Jan 31, 2008

- Location

- lexington sc

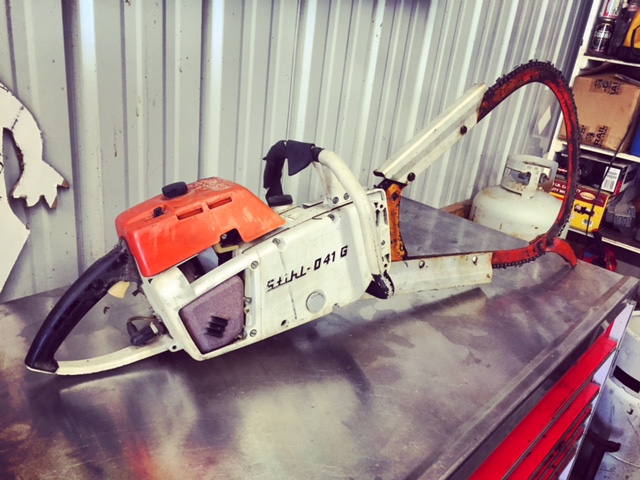

My saw is a 1976 Stihl , my grandfather traded a car for it in 76 , he's 87 so he doesn't need to use it , gave it to me , did a carb rebiuld and its going strong . It will make a man out of you , no vibration damping , no chain brake , weighs almost 20 pounds , over 20 lbs with the bow on it , uses a .404 chain.

Attachments

- Joined

- Apr 16, 2005

- Location

- Sharon, SC

Mine is new ...bought when I started this thread. I've since picked up an older saw and it has no issue. the vibe dampening seems to transmit the vibes to the case

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

Interesting. Putting better antivibe on the saw would further isolate the mass of the handle and probably fuel tank, basically lightening the mass of the vibrating member (that's what she said). But I would not think it would be enough to matter since even the old saws had springs. Also, the nuts are captive and loaded, so a slight change in frequency or amplitude really shouldn't make a difference. I'd guess the parts are now cheaper material. Is your side cover aluminum or plastic? Do the studs have anyou play in them when freestanding?Mine is new ...bought when I started this thread. I've since picked up an older saw and it has no issue. the vibe dampening seems to transmit the vibes to the case

mommucked

Endeavoring to persevere

- Joined

- Sep 26, 2011

- Location

- Rural Apex n.c.

Anyone had a problem losing bar nuts on a sthil? Often? Yes it gets cleaned.

Get the nuts snug then lift tip of the bar w you other hand as you tighten the nuts, or you can jamb a small log under the bar and push down on the handle to lift it while you tighten the bolts.If you do that they should stay tight. It's trial and error adjusting the tension/pushing the bar upwards, but when you get it right you'll see the chain drop a bit under the bar when you lift the bar and tighten and you'll have the right slop to let the chain run it's best.

Last edited:

Dirt Mcgert

Well-Known Member

- Joined

- Jan 31, 2008

- Location

- lexington sc

mine had play on the bar studs , I stuck a piece of 3/32nd tig wire in there to take up the slack and that fixed my problems with the bar coming looseInteresting. Putting better antivibe on the saw would further isolate the mass of the handle and probably fuel tank, basically lightening the mass of the vibrating member (that's what she said). But I would not think it would be enough to matter since even the old saws had springs. Also, the nuts are captive and loaded, so a slight change in frequency or amplitude really shouldn't make a difference. I'd guess the parts are now cheaper material. Is your side cover aluminum or plastic? Do the studs have anyou play in them when freestanding?

- Joined

- Mar 13, 2005

- Location

- Raleigh, NC

Sounds like you should have bought a husky.

- Joined

- Mar 13, 2005

- Location

- Raleigh, NC

I take back the shit I said before. My favorite way to fell a tree is with a Warn.

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

It's more fun to push or pull them over, but then you gotta deal with the stump and hole. Loggers just chop and drop because they don't have to deal with it, and leave a bunch of stumps and tops for the next guy to cleanup.

- Joined

- Mar 13, 2005

- Location

- Raleigh, NC

Oh, I was going to chop and drop, but the fucker fell over.

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

But now you don't have to hire a stumpgrinder, and you can fill it with sand to give the kids a stealth sandbox!Oh, I was going to chop and drop, but the fucker fell over.

- Joined

- Mar 13, 2005

- Location

- Raleigh, NC

But now you don't have to hire a stumpgrinder, and you can fill it with sand to give the kids a stealth sandbox!

As of today, I have at least ten stumps that need ground. So that's not really changing the calculation.

paradisePWoffrd

Recovering Project Junkie

- Joined

- Nov 5, 2005

- Location

- Newton, NC

My saw is a 1976 Stihl , my grandfather traded a car for it in 76 , he's 87 so he doesn't need to use it , gave it to me , did a carb rebiuld and its going strong . It will make a man out of you , no vibration damping , no chain brake , weighs almost 20 pounds , over 20 lbs with the bow on it , uses a .404 chain. View attachment 230420 View attachment 230421

What size bar do you have on that?

I just picked up an 041. Was looking for an 044/046 but got this for a song.

Also, what have you used the bow for? Ive seen them, and they look cool, but i cant understand the purpose.

paradisePWoffrd

Recovering Project Junkie

- Joined

- Nov 5, 2005

- Location

- Newton, NC

As of today, I have at least ten stumps that need ground. So that's not really changing the calculation.

sounds like it would be worth buying a used stumpgrinder and re-selling after.... unless you plan to cut more.

That or using the fire or sugar tricks and wait them out.

frankenyoter

No Rain, No Rainbow

- Joined

- Mar 17, 2009

- Location

- DARK CITY

Use grits.Great way to dispose of Ants

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

You need a mini excavator.As of today, I have at least ten stumps that need ground. So that's not really changing the calculation.

- Joined

- Mar 13, 2005

- Location

- Raleigh, NC

That or using the fire or sugar tricks and wait them out.

Please elaborate. Is that cheaper than renting a stump grinder?

paradisePWoffrd

Recovering Project Junkie

- Joined

- Nov 5, 2005

- Location

- Newton, NC

Please elaborate. Is that cheaper than renting a stump grinder?

Drill holes in the stump.

Pour gas/diesel on the stump, let it soak in, light it up. Or pour a sugar water mixture on the stump and let nature take over eating the wood.

I wouldnt try either if its near the house though.

Looks like you can pickup a used grinder for $3-4k, and then resell later, or rent one for ~$1k per week from sunbelt. Not sure what the going rate is to hire it out.

Dirt Mcgert

Well-Known Member

- Joined

- Jan 31, 2008

- Location

- lexington sc

I have a 21" bar on it , the purpose of the bow , is how they logged back in the day , a guy with a regular saw would drop the tree , then the guy with the bow saw would limb it and cut it to length , the bow works great for trees already on the ground , you dont have to bend over , just lay the saw on the limb and let its own weight cut through the branch .What size bar do you have on that?

I just picked up an 041. Was looking for an 044/046 but got this for a song.

Also, what have you used the bow for? Ive seen them, and they look cool, but i cant understand the purpose.