Sorry you had some trouble. Glad you were at least able to run it some.

Here was my plan on the transaxle carrier fix up. What happened to you guys is what I suspected would happen eventually so I had figured out a way around it. I had also spoke to BigJuggys cousin 94s10? ( on Pbb) he's running the Tarsus transaxle buggy. His spud shaft feeds a 2nd tcase so there is no constant pulling on his spud, so his works fine that way.

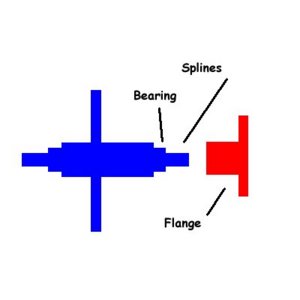

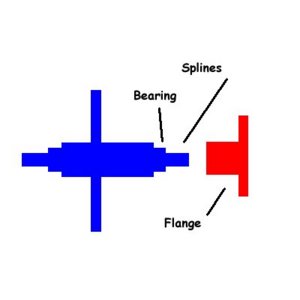

If you can implement this in the same way or similar with mods will depend on a few variables. Anyway its hard to explain so bear with me.. ( i made a pic to help)

- picture replacing your carrier with a spool and attaching a toyota flange on each end. The flanges come off for case reassembly. The bull gear attaches to the spool.

- For my plan the flanges would be standard toyota 3rd member flanges.

- The ends of the spool rather than be bored and splined internally like a typical spool, would have a external splined section extending out past the bearing mounting area.

- The flange could either be attached via a nut like oem or a hole drilled/tapped for a bolt to be used.

- I was able to source a off the shelf seal that had the correct size OD as well as ID for the toy flange (and correct material, lips etc) But you could resizing the OD of the flange if needed.

- then the driveshafts just run standard toyota ends