My first thought was 400 cases of coorsShe said it was Busch Lite.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Random pic thread.

- Thread starter MadAR15

- Start date

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

guess it wasn't that Lite.She said it was Busch Lite.

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

Yeah, police report stated it was just regular Busch that had been mislabeled.guess it wasn't that Lite.

awheelterd

Well-Known Member

- Joined

- Oct 18, 2007

- Location

- Kenly, NC

They don't really have frames. They're essentially unibody tubes. That aluminum strip at the bottom is flat with cross members riveted between. The walls do all the work. Id be willing to bet there was a problem with the roof or wall that contributed to the failure. They also likely loaded it wrong. Add in the bump and that's what you get. I had a buddy whose employee split a hopper bottom trailer full of corn coming out of a field too heavy and too fast.Frame definitely buckled, gotta be from rust, but also there's a railroad track about 100-200ft behind where that truck is sitting, and it has a pretty pronounced transition as you come off of it.

View attachment 411143

I'm guessing cracked or rusted frame, plus heavy load, plus a little too much air off the train tracks made it go all Bud Lite and collapse.

The Gashouse never lets you down!My mom sent me these pics she took in Gastonia earlier today.

View attachment 411141View attachment 411142

LT1JEEP

Well-Known Member

- Joined

- Jul 25, 2008

- Location

- HARLAN, KY

North Carolina state line.

skyhighZJ

Gov retirement < needs to live

- Joined

- May 31, 2012

- Location

- Aberdeen, NC.

Well the car facing in the pic is a ‘52 ford but other than that I’ve got nothing

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

As if I didn’t have enough out of the ordinary today, apparently it’s have a bat sneak in while your shop door is open and take a nap on the ceiling day too

mbalbritton

#@$%!

- Joined

- Mar 22, 2005

- Location

- Orlando, FL

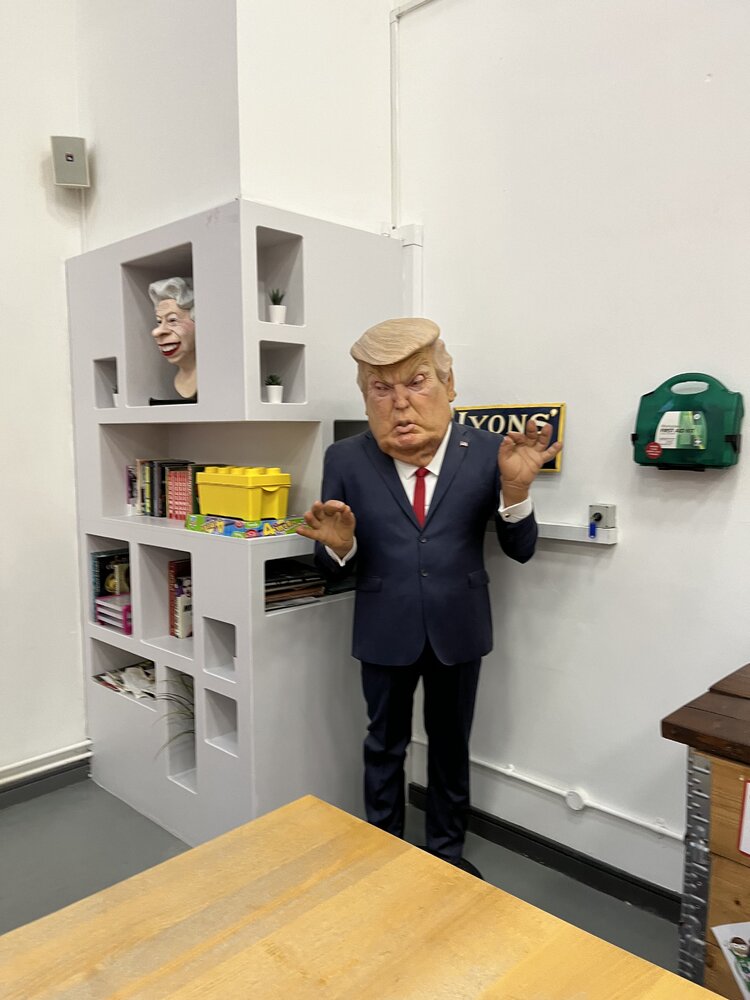

So, for Work, I’m in the LEGO Production team. One of the other divisions makes the wax models for Madame Tussaud’s Wax galleries around the world. At our headquarters here is the studios where they sculpt the models. Here’s a fun one in the breakroom of the studios

paradisePWoffrd

Recovering Project Junkie

- Joined

- Nov 5, 2005

- Location

- Newton, NC

To me, the real question is... what value did they think cutting the hole in the side was going to give them? The rear doors are open, so its not like access is an issue.I can't imagine the fun in dealing with getting that emptied and off the road.

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

I'm guessing they wanted to see what things looked like inside. And with the bottom being sloped like that, nobody would want to be going in from the rear w/ a forklift.To me, the real question is... what value did they think cutting the hole in the side was going to give them? The rear doors are open, so its not like access is an issue.

I assume to get it emptied you have to jack up the center however you could to get it more or less level so that forks and pallets could do some work?

mbalbritton

#@$%!

- Joined

- Mar 22, 2005

- Location

- Orlando, FL

JSJJ388

GREEN GREMLIN

- Joined

- Aug 31, 2016

- Location

- HAMPTONVILLE, NORTH CAROLINA

Heavy haulin lol

Tom@Hilltop_Machine

Well-Known Member

- Joined

- Mar 31, 2005

- Location

- Rural Retreat, VA

orange150

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Fairfax City, VA

Trying this

Because this makes me sad

Because this makes me sad

braxton357

Robot

- Joined

- Apr 6, 2005

- Location

- Morganton

To me, the real question is... what value did they think cutting the hole in the side was going to give them? The rear doors are open, so its not like access is an issue.

Have helped out with something like this before. They cut the hole because some poor bastards are about to have to hand unload that dry van into another one.

Then hopefully will be able to convince the receiver that that's the same trailer and they definitely didn't total the other one and all the product is just like the warehouse loaded it

orange150

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Fairfax City, VA

That Salt Away worked really well! Didn’t touch it with a cloth and all the salt is completely gone. Needs to be washed still for sure, but in the interim with salt on the road and rain coming that gave me some good peace of mind.

Tom@Hilltop_Machine

Well-Known Member

- Joined

- Mar 31, 2005

- Location

- Rural Retreat, VA

ManglerYJ

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Lexington, NC

So, for Work, I’m in the LEGO Production team. One of the other divisions makes the wax models for Madame Tussaud’s Wax galleries around the world. At our headquarters here is the studios where they sculpt the models. Here’s a fun one in the breakroom of the studios

View attachment 411175

That is awesome!!!! We actually had a small crew from Lego tour our facility a couple months ago. Not sure where they were from or what they hoped to get from us, but we produce laminates and TFL wood products. I just saw them get out of their car and throw on hi-vis vests that had Lego logos emblazoned on them. I can recognize that logo from a mile away.

- Joined

- Mar 20, 2005

- Location

- Hendersonville, NC

Dolla, Dolla

1-tonmudder

Doin my part to stir the pot.

- Joined

- Apr 17, 2005

- Location

- Greeneville TN

I understand its just how a case spreader works and its a common procedure but it still suprises me that a axle center section can be spread like that.

1-tonmudder

Doin my part to stir the pot.

- Joined

- Apr 17, 2005

- Location

- Greeneville TN

- Joined

- Mar 20, 2005

- Location

- Hendersonville, NC

I only use them on air locker installs. This one took some really creative shimming since the customer bought the wrong one and they're in Africa on deployment. No big deal really.I understand its just how a case spreader works and its a common procedure but it still suprises me that a axle center section can be spread like that.

Had to shim 0.200" on one carrier end, 0.030" under that bearing and then 0.150" on the opposing side. It took the spreader to allow me to squeeze so much shim in there.

Carrier preload is really imperative on an ARB. It keeps air leaks at bay and prolongs seal housing o-ring life