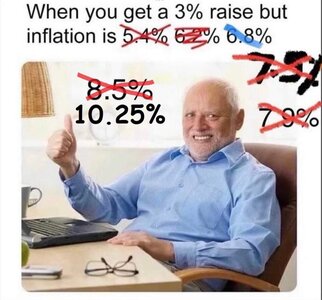

So, with respect to buying American rather than supporting our Chinese brethren, I do have a question. What has changed in the past 20-30 years that has caused american made goods to be so expensive? When i was in high school, i could go to Sears and buy made in America craftsman wrenches on money that i made at my minimum wage after school job. Now, you literally have to pay hundreds of dollars for a set of american made combination wrenches. Was the labor market in the US really that different then? I get that china and all these other countries were/are able to undercut us due to their 3rd world labor rates and unsafe work practices. etc, but it just seems like the price of American has also skyrocketed during that same time frame?

Dilution of the value of the dollar because there are so many of them (aka inflation), and also, because we don't make much in this country anymore, we don't have the resources in place to do it efficiently. To run with Southern Transplant's example...

As you mentioned, I've been guilty of buying a Chinese made product (front bumper) that may not be a Tera flex work of art, but at 25% of the cost it has clean welds, holds my winch, and has been doing great on my Jeep.

I might be in the small minority here, and I'm putting my flame suit on, but can someone explain the overall problem we're solving here?

I imagine that Chinese bumper is $400 and they make hundreds or thousands of them per month, in a factory where they also make them for a zillion other vehicles and companies, so it makes sense to invest in resources and equipment for mass production, and the machines, welders, and support equipment are also primarily made in China, and the knowledge to design and build this equipment is in China, and the raw material production is in China (or sold cheaply to China due to massive volume contracts). In the US, it is designed by some overpaid engineer in a plush office staffed by a bunch of salesmen and managers and secretaries (I'm taking some liberties here

), fabbed by a medium size fabrication company with similar overhead who also needs to turn a profit on it, constructed using material that was either made in the US or shipped in from overseas, and finished by a 3rd party powdercoater who also has overhead and needs to make profit. Each of these entities wants to make a profit, plus there is transportation cost every time it moves. In the China example, it is all probably done under one roof or in one complex, packed into a container, and then lands in California where some importer buys them for $150 each and sells them for $400 each. By the time that Teraflex bumper is done, the sales price is probably $1500 because of all the hands involved, and while it may be a "work of art", it doesn't function any different.

Even ignoring any government intervention or currency manipulation, most of Asia is already setup to win the price contest. Plus they don't design anything, they just copy and tweak, so that part of the overhead is completely eliminated. And somehow the shipping companies have to be complicit in encouraging this, because it would cost me $10 to send a box of feathers from NC to SC, but I can go on ebay or amazon and buy something from China that weighs 10lbs for $3 with free shipping.

From the industrial revolution through the 1960's, everything was made here, everything was innovated here, and most of the raw materials came from here. I don't know exactly what changed, but for the things I mess around with (machine tools, tractors, etc) it started in the 70's, and by the late 90's it was in full force. The art of design was replaced by the pursuit of lower cost and higher profits, and then the internet opened up a world of opportunity for online shopping and communicating with other people in other countries. These are not bad things, but they are factors that have contributed.

For folks like me it would never work cause I never watch TV or listen to celebrities and I think influencers are the stupidest thing ever.BUT I probably wouldn't be the targeted audience either.

For folks like me it would never work cause I never watch TV or listen to celebrities and I think influencers are the stupidest thing ever.BUT I probably wouldn't be the targeted audience either.