- Joined

- Mar 17, 2005

- Location

- N. N. Raleigh, NC

Been kicking aorund some ideas with Harper about various downsized camping ideas.. With the main goal being warm/cool dry sleeping with some room to stow some supplies..

Everythign from the sleeper cab idea, home built sleeper box, normal pickup box w/ standard cap, etc..

With the work body a normal cap won't fit and my body has the tops that open up. It was a plumbing truck so the bins are only 4" deep perfect for camping supplies, pots pans etc.. Anyway, I still need to open them..

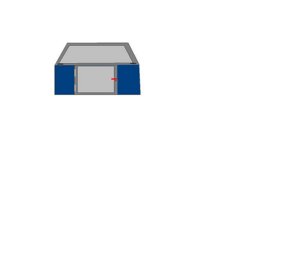

So i penciled out a very rough idea of what it might look like.. Ive found a few small rv style doors on ebay so i know they do make them relitivly short. I like the idea of an actual door, w/ window and a lock on it.. etc..

The 'box' would be made so each of the panels comes apart so I can store it when i need a normal truck, but the box would be sturdy enough to be left on the truck full time if needed.

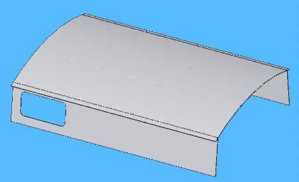

I'm thinking light guage (16ga) 1" box for the basic frame work, one edge would be cut open so the plywood could be 'inserted'. The panels would be made so that the seems had overlaps covering any 'gaps' and a standard foam sealing tape used.

Thinking if the front panel went in first, then the sides into some notches, with the frame work sort of interlocking it would hold it self in position, then the rear would be cliped on and fastened, followed by the roof having an overlapping type edge that fit over the side panels.

The plywood would have an exterior coating applied.. Some windows, shelf inside...

See rough hack picture...

Everythign from the sleeper cab idea, home built sleeper box, normal pickup box w/ standard cap, etc..

With the work body a normal cap won't fit and my body has the tops that open up. It was a plumbing truck so the bins are only 4" deep perfect for camping supplies, pots pans etc.. Anyway, I still need to open them..

So i penciled out a very rough idea of what it might look like.. Ive found a few small rv style doors on ebay so i know they do make them relitivly short. I like the idea of an actual door, w/ window and a lock on it.. etc..

The 'box' would be made so each of the panels comes apart so I can store it when i need a normal truck, but the box would be sturdy enough to be left on the truck full time if needed.

I'm thinking light guage (16ga) 1" box for the basic frame work, one edge would be cut open so the plywood could be 'inserted'. The panels would be made so that the seems had overlaps covering any 'gaps' and a standard foam sealing tape used.

Thinking if the front panel went in first, then the sides into some notches, with the frame work sort of interlocking it would hold it self in position, then the rear would be cliped on and fastened, followed by the roof having an overlapping type edge that fit over the side panels.

The plywood would have an exterior coating applied.. Some windows, shelf inside...

See rough hack picture...

not as tall and only as wide as the 'bed' area (48.5") ill still be able to open the top lids etc.. When i take a rear picture it will better show how the top lids are on there and what I have to work with..

not as tall and only as wide as the 'bed' area (48.5") ill still be able to open the top lids etc.. When i take a rear picture it will better show how the top lids are on there and what I have to work with..