Been making progress, but mostly on boring things that don't make good pictures, unlike completely banana peeling your RV. Lots of wiring getting done.

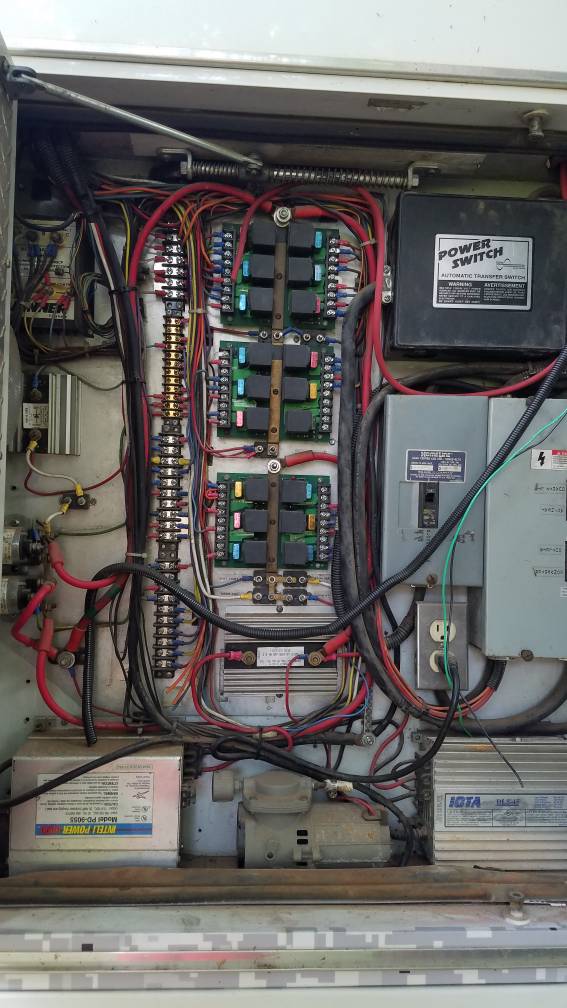

Here's the distribution box. Easy to work on and plenty of room for all my circuits.

I guess one interesting thing was the battery cables. Form what I read, it seems to be common for this vintage of truck... the cables corroded from the inside out at 2 of the ends.

I was getting a large voltage drop to the engine when the glow plug relay closed, making it hard to start without plugging in. It seems like this may have happened on other cables previously and somebody quarter-asked the replacement.

The cables are a mix of 1AWG, 1/0AWG, and 3/0AWG, but they used 4/0 terminals for every wire. On top of that, they only got about half of the conductor into the terminal on the 3/0 wire:

Proper terminals, heat shrink, and new posts has it all fixed up.

I glued and screwed mine. Smash it up and let it sit for a couple days.

I glued and screwed mine. Smash it up and let it sit for a couple days.