I suppose I should update this thread to preserve some sort of linearity. I don't really have an pictures of new parts because there haven't been any. I have been driving it around to flush out any remaining mechanical problems, and caught a big one on a recent trip.

A buddy and I took it from Winston up to DuPont Forest for some mountain biking last weekend. As luck would have it, a member up that way wanted a set of wheels i had so we agreed to meet at the Rural King in Morganton to do the swap. Having never been in before, we decided to check it out after handing off the wheels. We ended up buying some random stuff including ratchet straps, a funnel, tape, gloves, and some other stuff for no real reason.

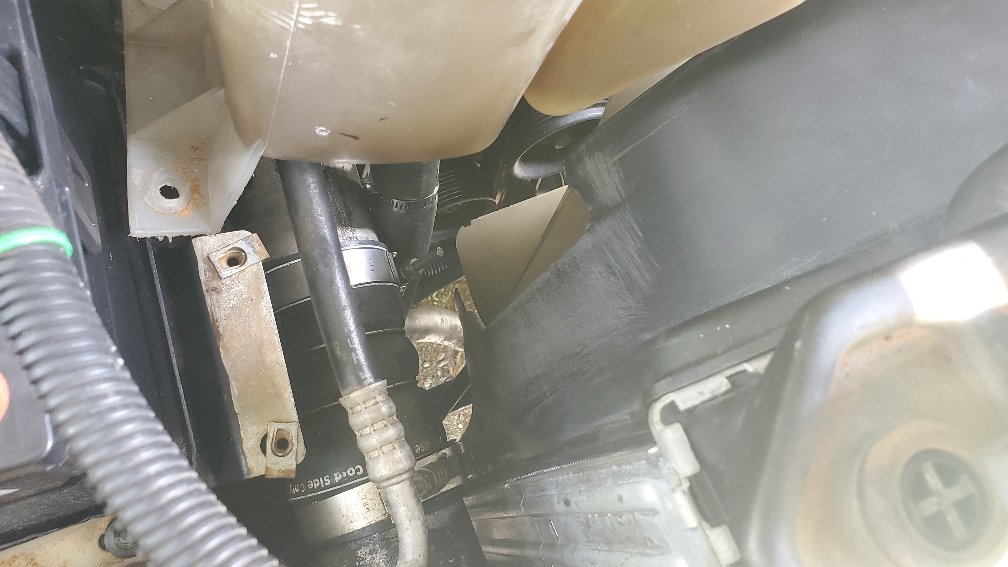

Fast forward an hour or so, quite near the top of the grade going into Ashville the odor of coolant becomes... noticeable. No change in the temp gauge, so we keep on truckin'. Once we get past town we pull into a gas station to snack up and find a nice stream of coolant coming from underneath. It wasn't hard to find the culprit. The fan had eaten the shroud and started on the surge tank hose.

Being at the gas station gave us pretty good resources to get it patched up. But the key was the Rural King haul. My friend sawed up the funnel spout while I got everything torn down.

We were able to stick the funnel spout down into the hose and put clamps on either side of the hole in the hose

You can see the tank isn't bilted back into place, obviously because the fan would have kept on snacking, so the ratchet strap (also bought at the King) held it to the side of the shroud out of danger.

The bodge was good enough to get us down to DuPont and home the next day.