You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Frankenstein Street Queen (a.k.a. SpeedBump)

- Thread starter ckruzer

- Start date

paradisePWoffrd

Recovering Project Junkie

- Joined

- Nov 5, 2005

- Location

- Newton, NC

I have also seen folks drill out the nuts from the bottom and weld in a plate with new nuts to the bottom of the rail.So hole saw the side of the rail and then drill out the old and weld in new nuts? Should I plate over the access hole or leave it?

I prefer to window the side cuz welding upside down sucks.

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

Also , could weld healthy angle iron on side of frame (length wise) and thru bolt skid plate.

Nice build!

Thanks man! I’m actually thinking along those lines as I am doing a flat belly skid and i don’t want the bolt heads getting rock rashed

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

My turning radius sucks balls. Any recommends? Also my steering wheel was off center by a couple degrees. Rotated the drag link to center it. Now there is a drastically big difference turning right versus turning left. I would have said the pitman or shaft is off a tooth but both are keyed and the steering wheel was never 180 out. Maybe 40-60

Left = Jeep like tight turn

Right = 10 point turn

Left = Jeep like tight turn

Right = 10 point turn

- Joined

- Mar 20, 2005

- Location

- Hendersonville, NC

Which pitman arm you running? How long is it center of splined hole to center of drag link and tie rod holes?

NCJeeplover

Well-Known Member

- Joined

- Jul 25, 2009

- Location

- Claremont, NC

I always like the way this guy did his yj skid....

95 Yj build on the cheap. (snowball) - Pirate4x4.Com : 4x4 and Off-Road Forum

Post 24

95 Yj build on the cheap. (snowball) - Pirate4x4.Com : 4x4 and Off-Road Forum

Post 24

iwaxmyjimmy

College Web Wheeler

- Joined

- Mar 10, 2007

- Location

- Greenville NC

5/16" Threaded Weld washers, Set of 6

I’ve fixed a YJ skid using this sort of thing. They have a few other sizes. But I would def make it modular so you can drop the belly pan without it being attached to your trans mount.

And I second Jody’s advice of finding the length of your pitman arm vs. your steering arm. Matching those gives you full range of motion. But it does sound like you need to center your box.

Edit: I use counter sunk bolts when I do skids. I use anti-seize on the threads and I’m careful to not look like the Tinman when I’m done. But ppl complain that you can’t get to the Allen head and it’s easier to drill the head out on those and replace a $2 fastener. Instead of dicking around with a grade 8 bolt head all mucked up. Plus everything smooth as a babies ass looks cool and slides great.

I’ve fixed a YJ skid using this sort of thing. They have a few other sizes. But I would def make it modular so you can drop the belly pan without it being attached to your trans mount.

And I second Jody’s advice of finding the length of your pitman arm vs. your steering arm. Matching those gives you full range of motion. But it does sound like you need to center your box.

Edit: I use counter sunk bolts when I do skids. I use anti-seize on the threads and I’m careful to not look like the Tinman when I’m done. But ppl complain that you can’t get to the Allen head and it’s easier to drill the head out on those and replace a $2 fastener. Instead of dicking around with a grade 8 bolt head all mucked up. Plus everything smooth as a babies ass looks cool and slides great.

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

When I first installed the box and the drag. I made the tires measuring tape straight. I then marked the box full sing both directions then split that and centered the arm on that, supposing to be true center swing of the arm. Made drag fit. Steering wheel was off the few degrees mentioned.

Never messed with it till yesterday. I always noticed a slight difference in how tight I could steer one way vs the other. But with the change it’s super noticeable now. Went to pull in to drive way and didn’t make it. Had to back up and try again. Smh.

Thanks for the tips on the skid guys. Gotta go pick up some sheet steel!

Never messed with it till yesterday. I always noticed a slight difference in how tight I could steer one way vs the other. But with the change it’s super noticeable now. Went to pull in to drive way and didn’t make it. Had to back up and try again. Smh.

Thanks for the tips on the skid guys. Gotta go pick up some sheet steel!

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

So. Quite an interesting few days. Took it out for some light overlanding and camping. Was a blast!

Wheeled up the mountain with the drag on the outside and the tie rod on the inside. Went fine. Well before wheeling I thought I better fix this extreme limitation with passenger turns. Well moved the tie rod to the stock location the knuckle under the leafs. It barely scraps the diff a bit just before full lock driver. Then moved the drag to the inner hole on the high steer arm sheikh marches the length of the pitman arm. 6 inches.

Man did it turn like a dream!!! And i straightens the steering wheel and I could turn either way on a dime! Well hit the first obstacle. 4Lo and and came up on a massive rut and the tire slipped in it and coming out of it the tire turned ripping the steering out of my hands. Loud popping and grinding. Looked for broken ujoints. Nothing. Hoping not a hub, already?!?!

Well I get back in and back out. Decide to head back to camp and get some tool time to figure out what’s up. Just as I pull into camp *bamm* and my steering wheel is free spinning.

Yikes!

I’m literally 3 miles from the nearest pavement at this camp site and it is literally not accessible by anything that doesn’t have lockers.

Well find out the steering shaft fell off the box end. I guess there was enough flex and twist that it popped loose.

Well it either recessed more in the telescope tube or something. At full engagement on the column there was only about 1/4 inch engagement now on the box splines. And this POS shaft is frozen rust solid. No telescoping capabilities whatsoever.

Sooo... when you don’t have a torch but you’re camping....

Well. That did not work. Tried lots of ideas. But ended up with 1 inch engagement on the box splines and about 3/4 inch engagement on the column shaft. Ok. Golden. Right?

Well at one point we were given access to some forest service roads. It was a blast. Well one path we went down. Dead end. I got pretty vertical (felt that way) with turning around. Fun!!! Well. I quickly found out how much a drag link on a six inch arm greatly changes the forces put on a stock box!

Well. You can guess what happened. Snap. Crackle. Pop. And a few other ones. Face palm. Snapped the steering box halfway off the frame. Broke one of the three mounts.

I ease it back to camp. During this easing... lots and lots of grinding. The box is flexing so much the steering shaft is contacting the PS pulley.

Well. Long hairy story short getting off the mountain today, it summed up to extra tight bolts on the other two mounts and a ratchet strap for extra security and a very very long slow crawl. Lol

Anywho. It’s home and back in the garage now. Time to add hydro assist I reckon. Oh and also a new steering box. Haha. I also was not a fan of my braking power and I really suspect it is the flexible brake lines I used. Swapping all these out for hardlines. Also time for a new shaft that actually telescopes. Don’t think I want to break for a borgeson. I’m tempted to make my own with some square tube, if others here agree that’s safe (street rig too). Otherwise just get a stock YJ shaft that works.

Realistically I don’t know if I will have the time for any of it and next trip is end of June. May have to outsource on this one for the sake of time management.

Wheeled up the mountain with the drag on the outside and the tie rod on the inside. Went fine. Well before wheeling I thought I better fix this extreme limitation with passenger turns. Well moved the tie rod to the stock location the knuckle under the leafs. It barely scraps the diff a bit just before full lock driver. Then moved the drag to the inner hole on the high steer arm sheikh marches the length of the pitman arm. 6 inches.

Man did it turn like a dream!!! And i straightens the steering wheel and I could turn either way on a dime! Well hit the first obstacle. 4Lo and and came up on a massive rut and the tire slipped in it and coming out of it the tire turned ripping the steering out of my hands. Loud popping and grinding. Looked for broken ujoints. Nothing. Hoping not a hub, already?!?!

Well I get back in and back out. Decide to head back to camp and get some tool time to figure out what’s up. Just as I pull into camp *bamm* and my steering wheel is free spinning.

Yikes!

I’m literally 3 miles from the nearest pavement at this camp site and it is literally not accessible by anything that doesn’t have lockers.

Well find out the steering shaft fell off the box end. I guess there was enough flex and twist that it popped loose.

Well it either recessed more in the telescope tube or something. At full engagement on the column there was only about 1/4 inch engagement now on the box splines. And this POS shaft is frozen rust solid. No telescoping capabilities whatsoever.

Sooo... when you don’t have a torch but you’re camping....

Well. That did not work. Tried lots of ideas. But ended up with 1 inch engagement on the box splines and about 3/4 inch engagement on the column shaft. Ok. Golden. Right?

Well at one point we were given access to some forest service roads. It was a blast. Well one path we went down. Dead end. I got pretty vertical (felt that way) with turning around. Fun!!! Well. I quickly found out how much a drag link on a six inch arm greatly changes the forces put on a stock box!

Well. You can guess what happened. Snap. Crackle. Pop. And a few other ones. Face palm. Snapped the steering box halfway off the frame. Broke one of the three mounts.

I ease it back to camp. During this easing... lots and lots of grinding. The box is flexing so much the steering shaft is contacting the PS pulley.

Well. Long hairy story short getting off the mountain today, it summed up to extra tight bolts on the other two mounts and a ratchet strap for extra security and a very very long slow crawl. Lol

Anywho. It’s home and back in the garage now. Time to add hydro assist I reckon. Oh and also a new steering box. Haha. I also was not a fan of my braking power and I really suspect it is the flexible brake lines I used. Swapping all these out for hardlines. Also time for a new shaft that actually telescopes. Don’t think I want to break for a borgeson. I’m tempted to make my own with some square tube, if others here agree that’s safe (street rig too). Otherwise just get a stock YJ shaft that works.

Realistically I don’t know if I will have the time for any of it and next trip is end of June. May have to outsource on this one for the sake of time management.

paradisePWoffrd

Recovering Project Junkie

- Joined

- Nov 5, 2005

- Location

- Newton, NC

Sounds like your axle might have had more travel then your steering box. Also seems like alot of flex in those front rails to cause the steering shaft to come loose. Was there not bolts in the yoke where it slides onto the box/column?

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

Sounds like your axle might have had more travel then your steering box. Also seems like alot of flex in those front rails to cause the steering shaft to come loose.

What? You saying the frame has less travel than the axle? Sorry dont understand what you mean.

Was there not bolts in the yoke where it slides onto the box/column?

Yes it was secured with bolts. Maybe they were loose? there was no damage and the bolts were there.

paradisePWoffrd

Recovering Project Junkie

- Joined

- Nov 5, 2005

- Location

- Newton, NC

What? You saying the frame has less travel than the axle? Sorry dont understand what you mean.

I am saying that it sounds like the steering on your axle has 8" of travel vs 6" of travel in your pitman/box. Since the pitman and steering arm are the same length now, that would mean that one has more rotation then the other. The steering stops on the axle should bottom at the same time or just before your box reaches the stops. If not, the box could be maxed out and the tire rotated farther, pulling on the box. This can cause the box to break or potentially rip from the frame.

I would also inspect to see if there is any rust on the frame. It seems odd that the box would rip from the frame like that with no harder riding then it looks you were doing.

Yes it was secured with bolts. Maybe they were loose? there was no damage and the bolts were there.

I think the bolts must have been loose or too small if it pulled off. Most of the shafts I have seen also have a recess for the bolt to fit in, making slips more difficult.

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

I am saying that it sounds like the steering on your axle has 8" of travel vs 6" of travel in your pitman/box. Since the pitman and steering arm are the same length now, that would mean that one has more rotation then the other. The steering stops on the axle should bottom at the same time or just before your box reaches the stops. If not, the box could be maxed out and the tire rotated farther, pulling on the box. This can cause the box to break or potentially rip from the frame.

That makes alot of sense actually. I will need to either put in some steering stops or find another pitman arm. or at least one then the other.

I would also inspect to see if there is any rust on the frame. It seems odd that the box would rip from the frame like that with no harder riding then it looks you were doing.

No, no rust man. Well, based on what you said above it makes alot of sense if true.

I think the bolts must have been loose or too small if it pulled off. Most of the shafts I have seen also have a recess for the bolt to fit in, making slips more difficult.

Yeah there is a recess on the column and box shaft end. They are the stock bolts. Only explanation i can see is they were loose or the shaft was not all the way on the steering box to begin with.

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

Oh snap!

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

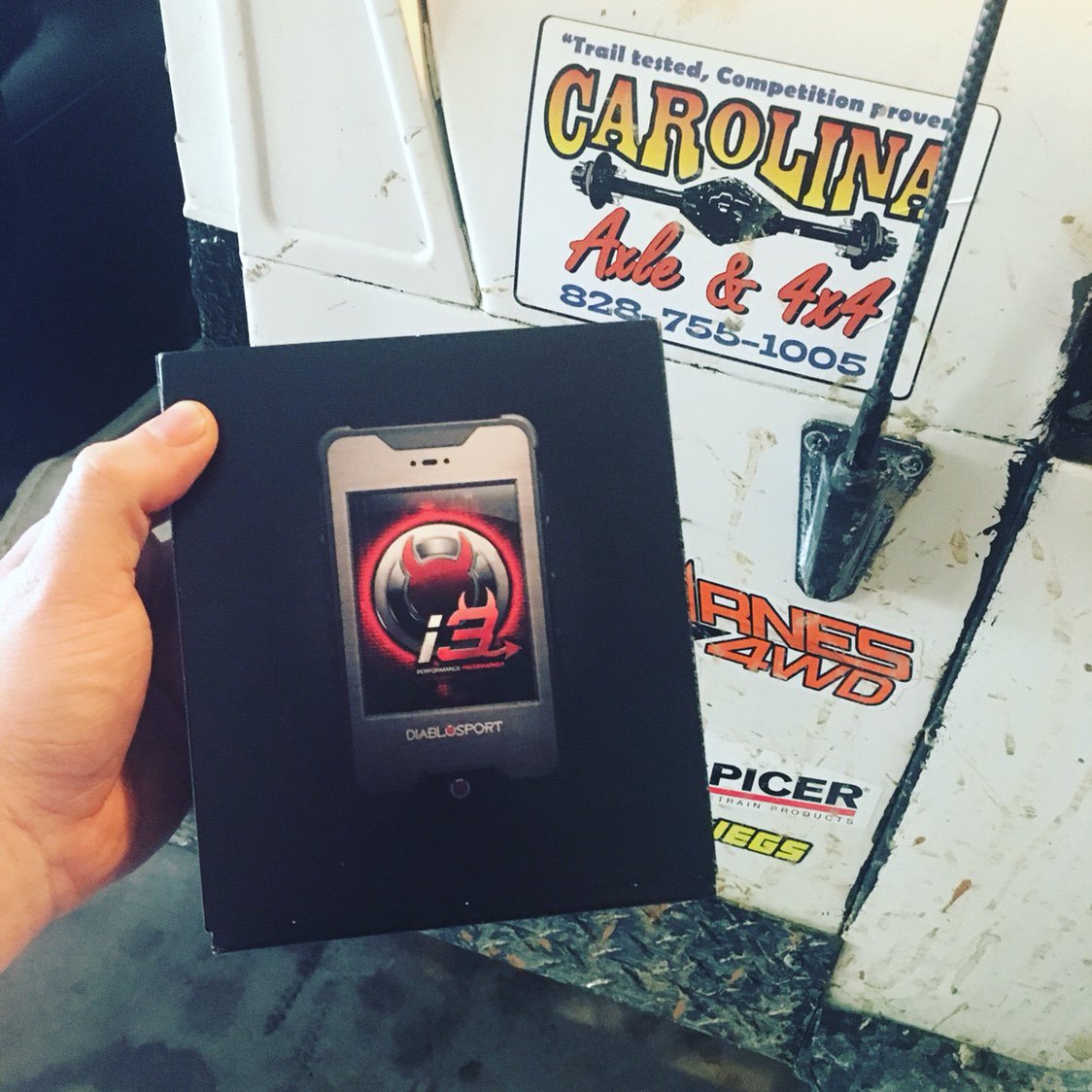

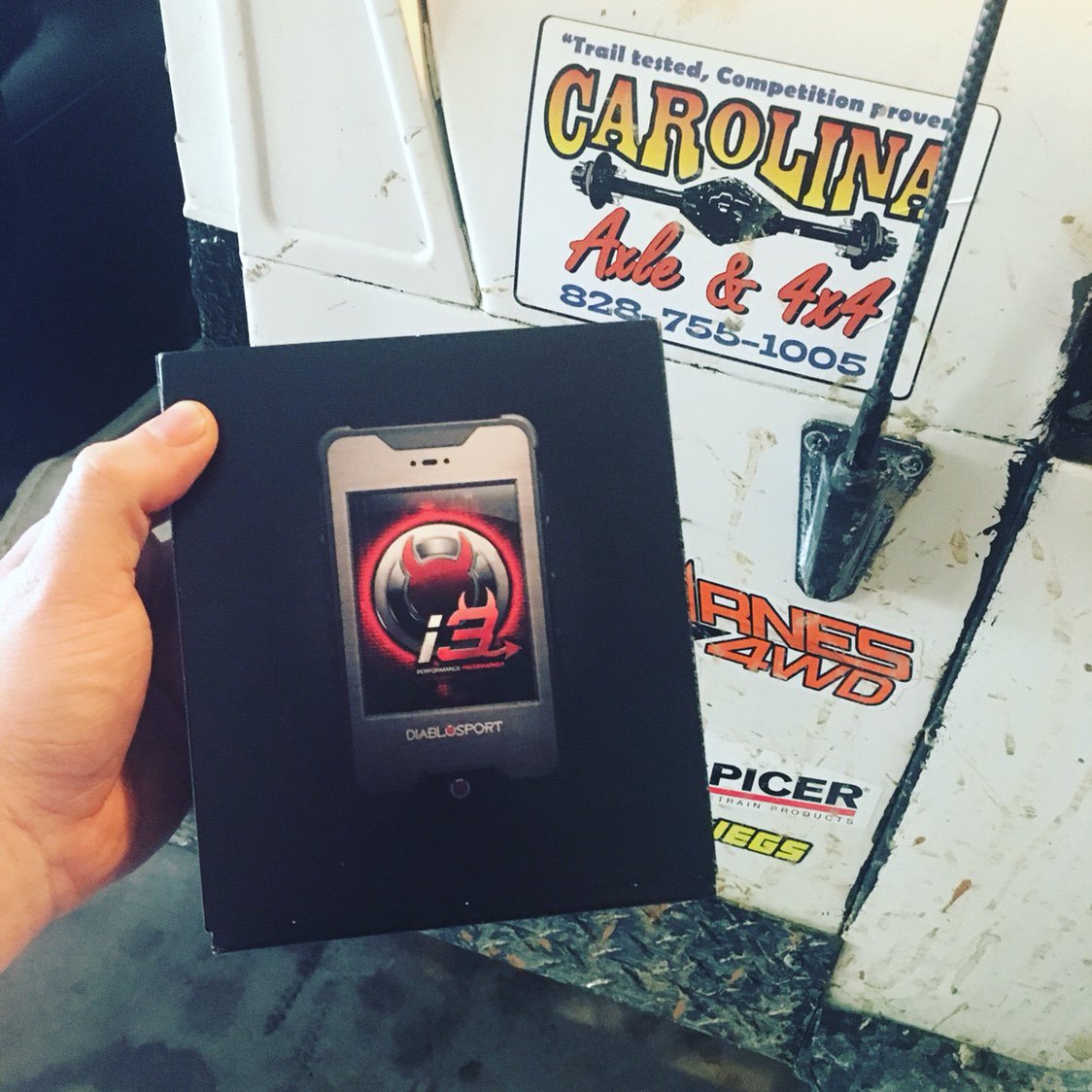

Shopping and about to place a order at surplus and barnes for the hydro assist setup. Gotta do some research on ram/throw knowledge etc.

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

D44 knuckle throw (stop to stop) can be anywhere from 6.5-7.5" depending on what knuckle you use. It's fairly easy to measure, and you want to be as close as you can get. There's internal spacers labeled as "shaft collars" available to fit any ram they offer. Best to go with a longer stroke and space it down. You can always remove the spacers later and reutilize the 8" full stroke on a 60. Getting the ram apart can be a feat, but I can walk you through it. The spacers I used years ago were .53x1" I stacked three together and called it a day.Shopping and about to place a order at surplus and barnes for the hydro assist setup. Gotta do some research on ram/throw knowledge etc.

BigSouth

Doesn't play well with others!

- Joined

- Jun 8, 2011

- Location

- Shelby, NC

So. Quite an interesting few days. Took it out for some light overlanding and camping. Was a blast!

Wheeled up the mountain with the drag on the outside and the tie rod on the inside. Went fine. Well before wheeling I thought I better fix this extreme limitation with passenger turns. Well moved the tie rod to the stock location the knuckle under the leafs. It barely scraps the diff a bit just before full lock driver. Then moved the drag to the inner hole on the high steer arm sheikh marches the length of the pitman arm. 6 inches.

Man did it turn like a dream!!! And i straightens the steering wheel and I could turn either way on a dime! Well hit the first obstacle. 4Lo and and came up on a massive rut and the tire slipped in it and coming out of it the tire turned ripping the steering out of my hands. Loud popping and grinding. Looked for broken ujoints. Nothing. Hoping not a hub, already?!?!

Well I get back in and back out. Decide to head back to camp and get some tool time to figure out what’s up. Just as I pull into camp *bamm* and my steering wheel is free spinning.

Yikes!

I’m literally 3 miles from the nearest pavement at this camp site and it is literally not accessible by anything that doesn’t have lockers.

Well find out the steering shaft fell off the box end. I guess there was enough flex and twist that it popped loose.

Well it either recessed more in the telescope tube or something. At full engagement on the column there was only about 1/4 inch engagement now on the box splines. And this POS shaft is frozen rust solid. No telescoping capabilities whatsoever.

Sooo... when you don’t have a torch but you’re camping....

Well. That did not work. Tried lots of ideas. But ended up with 1 inch engagement on the box splines and about 3/4 inch engagement on the column shaft. Ok. Golden. Right?

Well at one point we were given access to some forest service roads. It was a blast. Well one path we went down. Dead end. I got pretty vertical (felt that way) with turning around. Fun!!! Well. I quickly found out how much a drag link on a six inch arm greatly changes the forces put on a stock box!

Well. You can guess what happened. Snap. Crackle. Pop. And a few other ones. Face palm. Snapped the steering box halfway off the frame. Broke one of the three mounts.

I ease it back to camp. During this easing... lots and lots of grinding. The box is flexing so much the steering shaft is contacting the PS pulley.

Well. Long hairy story short getting off the mountain today, it summed up to extra tight bolts on the other two mounts and a ratchet strap for extra security and a very very long slow crawl. Lol

Anywho. It’s home and back in the garage now. Time to add hydro assist I reckon. Oh and also a new steering box. Haha. I also was not a fan of my braking power and I really suspect it is the flexible brake lines I used. Swapping all these out for hardlines. Also time for a new shaft that actually telescopes. Don’t think I want to break for a borgeson. I’m tempted to make my own with some square tube, if others here agree that’s safe (street rig too). Otherwise just get a stock YJ shaft that works.

Realistically I don’t know if I will have the time for any of it and next trip is end of June. May have to outsource on this one for the sake of time management.

I count 12 "well's", not including the one in your signature line. Sorry, OCD. At least you weren't saying "like".

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

That sound of music chick would be jealous

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

Ok. Looking for square tube and gunna fab up a simple steering shaft using the old ujoints.

Holding off the ram purchase until next month or after that. Whenever I can get to the steering and get the arm geometry and steering stops and everything hammered out

I got everything for the box tapping i think.

Holding off the ram purchase until next month or after that. Whenever I can get to the steering and get the arm geometry and steering stops and everything hammered out

I got everything for the box tapping i think.

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

D44 knuckle throw (stop to stop) can be anywhere from 6.5-7.5" depending on what knuckle you use.

been thinking on the steering lately. havent touched a wrench, tho. i think you are hitting on a key point i need to delve into. when i was at full lock and going through a rut, or even straight with the steering wheel ***not*** moving, the tire/wheel still had a odd amount of flex/play... It would flex back and forth alot before the steering wheel even started to move.

To note: this is with brand new tre's, reman TJ box, and new BJs. The one thing I never bothered to check/research/address was the pitman arm (right now stock durango arm that was on the durango box). Six inches. Which leads me to think when the box is at Max, the knuckle still has alot more to give, and seeing as how i never installed steerings tops, it was creating too much flex and which caused the box to rip off the frame?

I got to thinking really hard about all of this, because it really didnt make sense. Im always hearing of people without hydro assist doing the same stuff. Its just "harder".

Anywho. Back to more reading on the subject. Hopefully on the right track. Got coil fever lately, and really trying not to give into temptation to order truss and buckets from Barnes4wd and dropping off with Treadway for some badass links. Lol

EDIT; Pic for attention (buggy idea)

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

It's always one of the drawbacks of a leaf spring front application; the lateral axle movement you'll get through the leaf packs, shackles and even bushings. Even when everything is in new or like-new condition, you'll still get a fraction of side to side movement out of it, especially on the front steer axle. This is the exact reason you'll see track bars on stock Jeeps and several other vehicles put there from the factory. Even as little as 1/8" will be noticeable, and gets greatly compounded the larger the tire is. It's also very possible to get death wobble in the right condition. At my best attempt, I was able to dodge at or about 60% of the poor handling characteristics with mine, but in the near future a linked front is inevitable. Not saying that a well thought out leaf spring setup can't suffice in an all around daily driven wheeler, because I've owned a few that were, it's just these days a proper 3 link is apples to oranges.

paradisePWoffrd

Recovering Project Junkie

- Joined

- Nov 5, 2005

- Location

- Newton, NC

One way you can combat that a little is angle the springs slightly /\. Yes the springs will want to bind some during travel, but since most travel is articulation, it isn't very prominent. Helps a little to run short shackles also.

I believe you are on the right thinking. Many guys have broken steering boxes while offroad racing, with the same type setup, and even with hydro assist.

You do not want the box or ram to be your steering limit.

I believe you are on the right thinking. Many guys have broken steering boxes while offroad racing, with the same type setup, and even with hydro assist.

You do not want the box or ram to be your steering limit.

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

One way you can combat that a little is angle the springs slightly /\. Yes the springs will want to bind some during travel, but since most travel is articulation, it isn't very prominent. Helps a little to run short shackles also.

I believe you are on the right thinking. Many guys have broken steering boxes while offroad racing, with the same type setup, and even with hydro assist.

You do not want the box or ram to be your steering limit.

Well the good news then is that I’m already angled and on stock shackles!

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

Got old grille guard removed and new one out on for the wife

ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

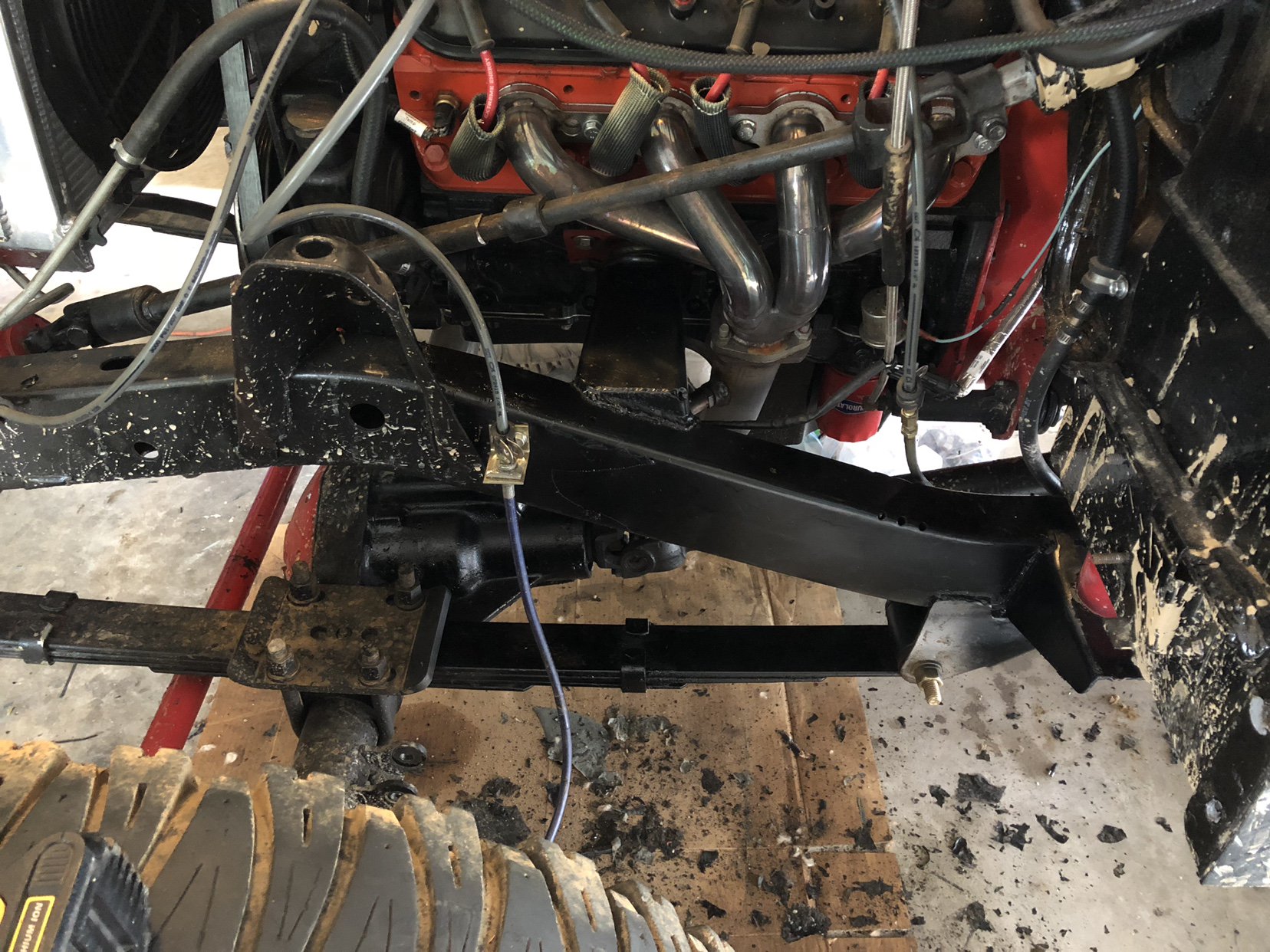

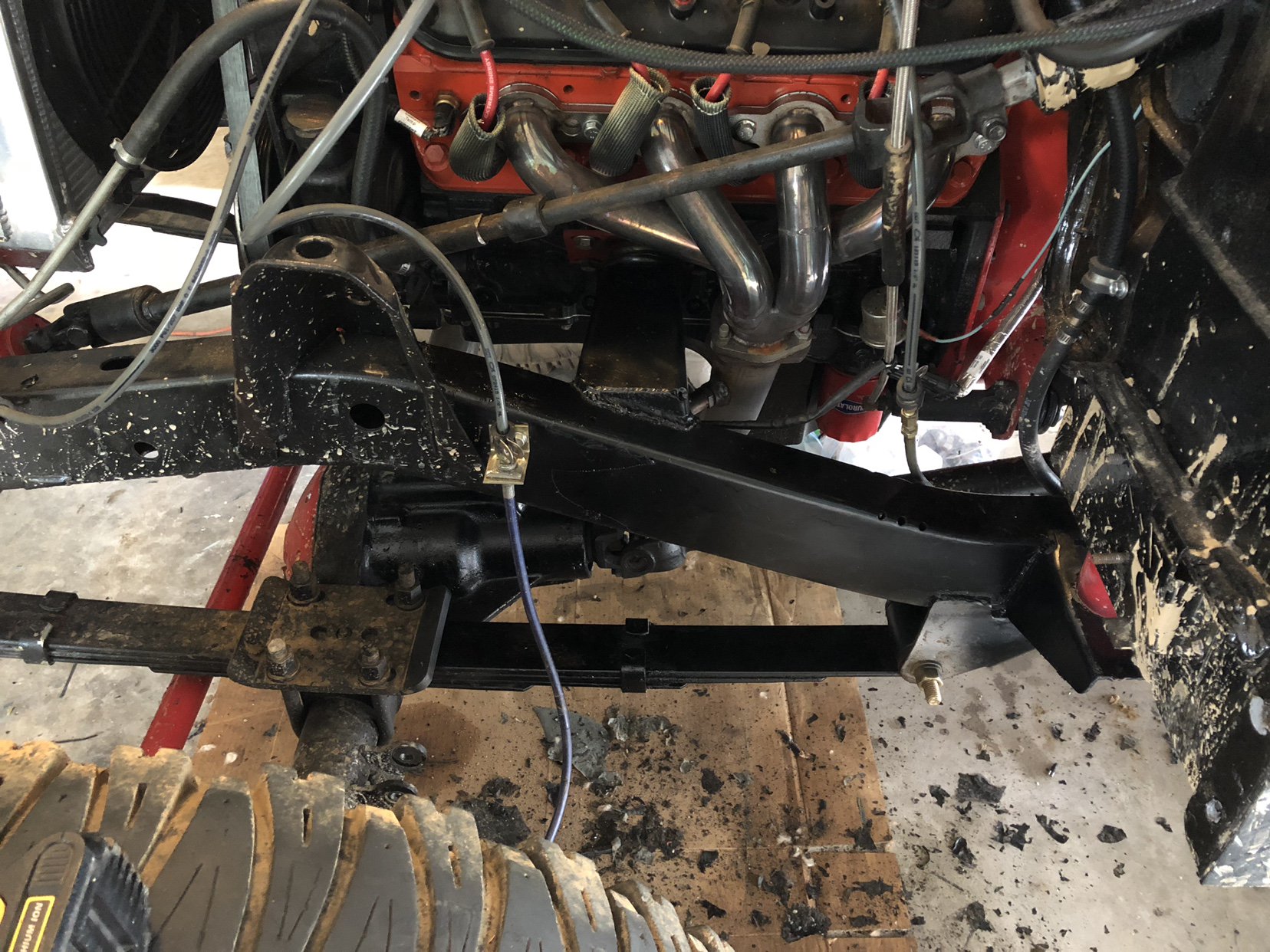

Mounted up a permanent location for the overflow. Finally. Lol. And test that is a buckle piece from a harness. Haha.

Fixed up the frame rail paint from the brake leak.

Touched up the front bumper paint and finally installed the turn signals and parking lamps. Also wired in the headlights as park lamps with soldered connections finally.

Fixed up the frame rail paint from the brake leak.

Touched up the front bumper paint and finally installed the turn signals and parking lamps. Also wired in the headlights as park lamps with soldered connections finally.