Bet some of you phockers thought I gave up on this piece, didn't ya?

Nah, it's just been busy. Finally got in the garage last weekend after moving a year and a half ago and started straightening some things out, putting them in their places, and throwing out a bunch of trash. I have soooo....muuuuch…..SH!T. It's not even funny. Anyway, I digress.

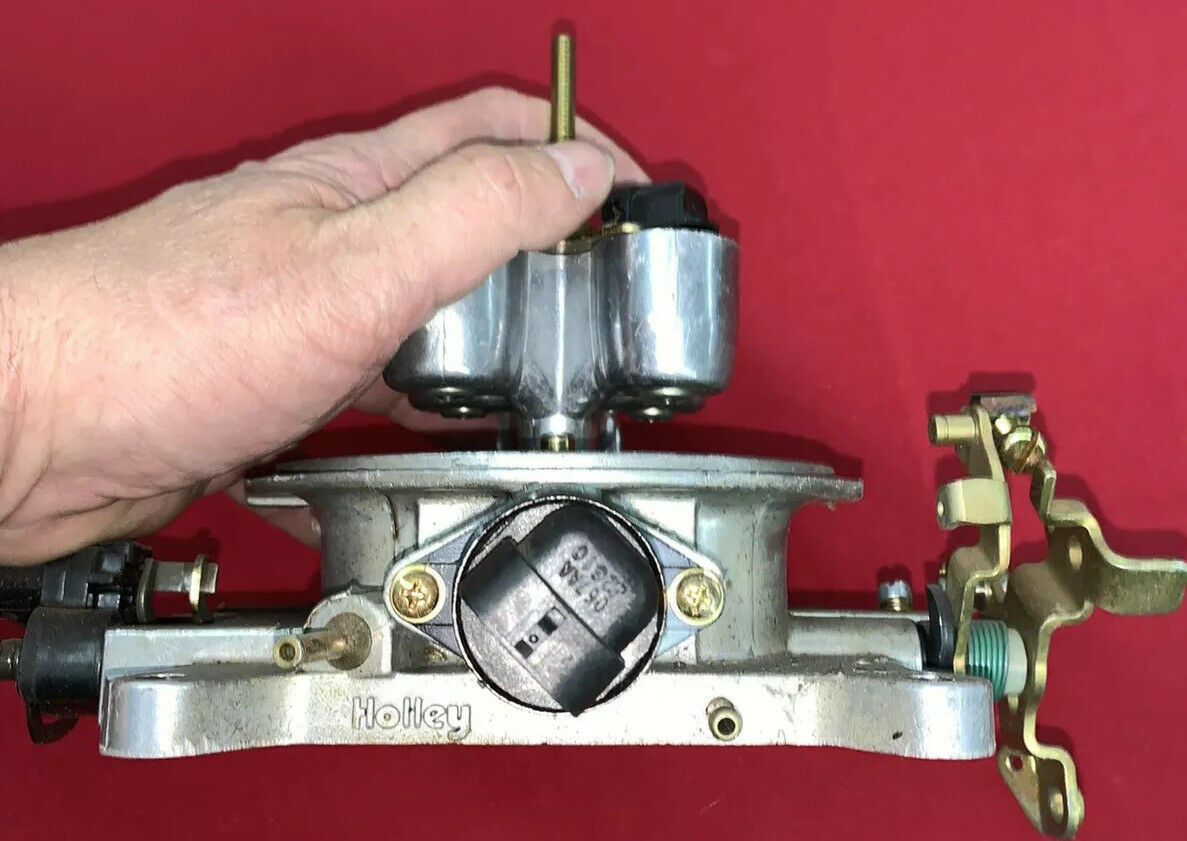

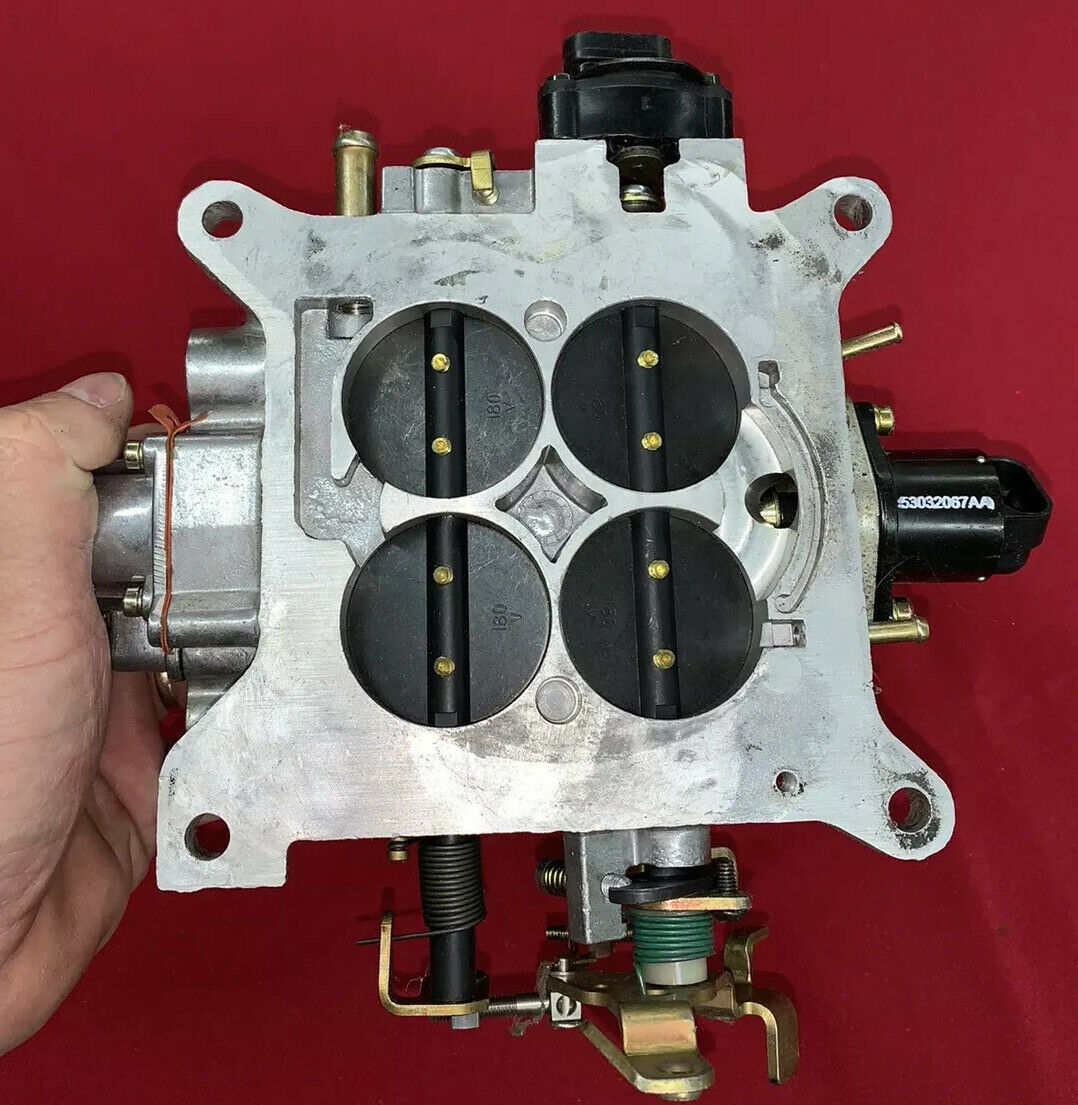

I have been thinking for a while about how to tackle the TPS/IAC/whateverdafuhkelse problems will arise from the ashes, and went to sniffing around on the fleabay. I ended making myself the proud new owner of what appears to be a gently used one of these:

The search started with looking at intake manifolds that will work with my heads (96+ Vortec is what it needs) that was a MPFI style, since I am beginning to hate my chopped up fuel rail thing that's going on.... I found one that the dude selling this had for a decent price for what was there (as I'm typing this, I see someone already jumped on it...too late for me (what else is new)). The seller of this also had another identical TBI setup that has all the wiring/connectors/etc, but for 2.5x the cost. I figured 'what the hell' and I'll give this one a shot.

It's a Holley 900 CFM Avenger TBI that, like I said, is complete less wiring. No issues here, I can source the connectors since I'd have to adapt them to my ECM anyway. My original intent was to remove the injector pod from the top, and just use it as a throttle body and a place to house the already integrated TPS (as long as it works, pending testing) and the IAC (same as TPS - need to check it out). But then I got to thinking....don't you hate it when that happens??

If these injectors are good, why would I worry about the cobbled fuel rail mess on my current manifold? That is, depending on their size. Dude selling this didn't say in the listing, I didn't care to ask since I was intending to remove them anyway. I'll run the numbers on it and see what they are for giggles and sharts.

One thing I lack (among many) is some electronic hardware to properly drive the IAC on this one....I am currently configured to run a PWM-style IAC, and this one is a stepper motor. So I'll have to source a stepper motor driver and a few more bits and pieces, probably put them on another daughterboard to fit to my ECM...no sweat, really. Then I'll go back into the tuner software and make the appropriate changes, and all "should" be happy here (or so I think). I guess it's a good thing I still haven't bought an IAC valve before I found this?

With my current intake manifold, I could remove the bungs I put in and cover the holes, or just replace the hoooge-as-fawk Frankenstein mess with a more appropriately sized one (which is the way I'm really leaning....go figure). I will admit, the intake I have on this engine is too big. It was paired up with a much bigger solid roller cam that used to live in the engine. Something in the 1500-6000 RPM range would be much more appropriate.

Or, I could drill/tap some adapters in and make a nitrous fogger kit.

nah, most likely not. And to think -- all this started because I was curiously searching for an LT4 intake manifold (the 90s version, not the modern sexy one). I was thinking I'd just get one of those, an oil pump drive, a handful of LS coil packs and go distributor-less with a slick looking top end.

Anyway, just wanted to update a little, and let y'all that are still out there know I haven't given up on this shit yet.

One of these months I might get back to actually working on something!

One of these months I might get back to actually working on something! Looks like I'll order the proper connector and just swap them out rather than pay more for shipping than I would on the correct connector. Who'da thunk that these have more than one connector type on them?

Looks like I'll order the proper connector and just swap them out rather than pay more for shipping than I would on the correct connector. Who'da thunk that these have more than one connector type on them?