Croatan_Kid

How's your hammer hangin'?

- Joined

- Nov 4, 2007

- Location

- New Bern

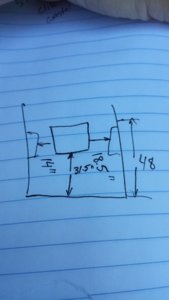

I've been looking at different sound deadeners on Amazon. I found one called FatMat that I like and it's pretty inexpensive compared to others. I'll probably get 100-150 sq ft of it and do the doors, all of the floor in the cab, and more than likely double layer some areas near the firewall.

Got home from work tonight and pulled the old tape player out and replaced it with the little storage bin thing. You just flip the lid up, take out two screws, the whole face plate comes off, you slide the tape deck out, put the compartment in, and reassemble. Pretty easy!

Got home from work tonight and pulled the old tape player out and replaced it with the little storage bin thing. You just flip the lid up, take out two screws, the whole face plate comes off, you slide the tape deck out, put the compartment in, and reassemble. Pretty easy!