RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

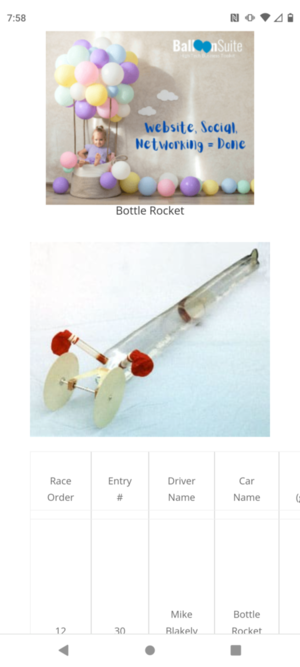

I've needed to make some really small parts for work. Got a 0.2mm nozzle for the Bambu.

Holy hell the detail is amazing. It will print down to 0.06mm z resolution. That's so tiny you can even see the transition lines on dones etc.

Here is a part at 0.12mm Z, nothing special there.. except there's no lines visible at all.

Can tab for scale.

The inner walls are 1mm thick. Since the lines are so tiny there's 5 per wall at even that size so it's plenty strong.

Also the above print is after zero fiddling or adjusting. Set the nozzle size, picked Z height, generic ABS settings and boom.

This printer runs circles around our Ulimaker.

Holy hell the detail is amazing. It will print down to 0.06mm z resolution. That's so tiny you can even see the transition lines on dones etc.

Here is a part at 0.12mm Z, nothing special there.. except there's no lines visible at all.

Can tab for scale.

The inner walls are 1mm thick. Since the lines are so tiny there's 5 per wall at even that size so it's plenty strong.

Also the above print is after zero fiddling or adjusting. Set the nozzle size, picked Z height, generic ABS settings and boom.

This printer runs circles around our Ulimaker.