RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

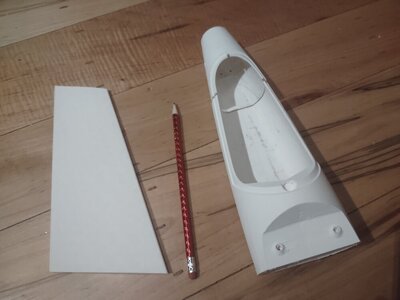

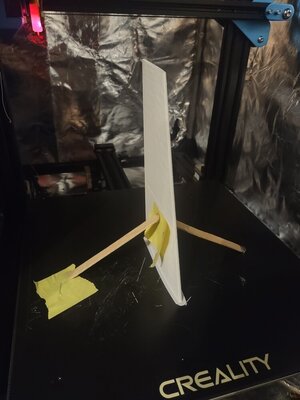

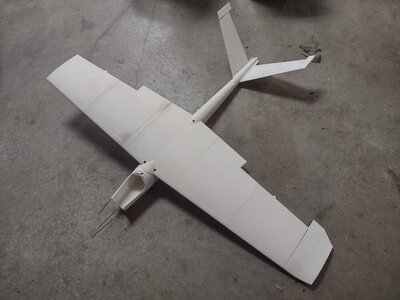

Note that a lot of the weight isn't the walls but the infill and top/bottom. Mathematically the perimeter is a small %. Depending on the design, sometimes you can get more rigidity with thicker walls and less infill anf floor/roof. It of course really depends on teh sape.Airplanes fly much better when they aren't heavy. A big problem printing single wall planes with PLA is weight, or so I hear, I haven't printed one yet.

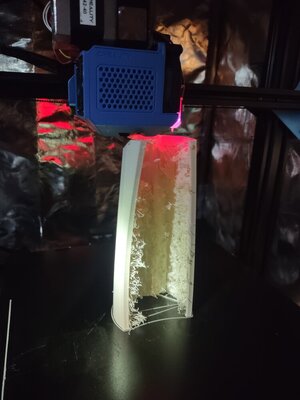

I just want to figure out how to get the inner structure to not show through....

Also you might try changing your nozzle thickness. Move up to 0.6mm, then you'll get 50% more thickness per line. I've read a lof of things that say that overall 0.6 leads to the strongest overall.