Wow. These are really getting close to consumer devices. Did you look at the Creality K1? I’ve been on the brink for a while but now may be the time to jump in. Prusa XL seems like a half step.Super stoked about this father's day present.

Weeks of hints I was going to buy it anyway paid off.

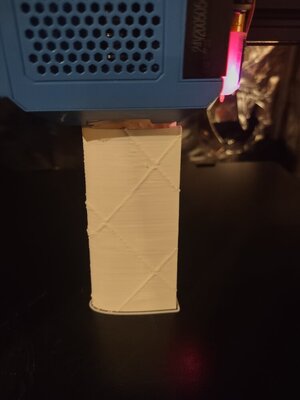

View attachment 399122

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

3D PRINTING

- Thread starter JSJJ388

- Start date

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

I did not. I have a Creality CR10 and a lot of experience working with the Ender series.Wow. These are really getting close to consumer devices. Did you look at the Creality K1? I’ve been on the brink for a while but now may be the time to jump in. Prusa XL seems like a half step.

I specifically wanted something that would just work out of the box, no fiddling or tuning or upgrades or buggy firmware etc etc. Creality makes some great budget devices but the money you're not paying them goes to refinement and idiot-proofness with other brands..

Plus I'm moving on to working with exotic materials and multiple materials in a print. The Bambu covers all of those bases. With a single materials station you can mix 4 materials in 1 print, and you can even combine stations for up to 16. And it's really, really, REALLY fast. The big hangup is its a closed ecosystem with their own slicer, black box firmware, most components have to be bought through Bambu, etc. But like Apple thats how they ensure it works well, by having control over everything.

Last edited:

That’s my read too. I quit building my own computers many years ago, rather use one than constantly fiddle with it. Spend more time working on getting the result right. Thx!I did not. I have a Creality CR10 and a lot of experience working with the Ender series.

I specifically wanted something that would just work out of the box, no fiddling or tuning or upgrades or buggy firmware etc etc. Creality makes some great budget devices but the money you're not paying them goes to refinement and idiot-proofness with other brands..

Plus I'm moving on to working with exotic materials and multiple materials in a print. The Bambu covers all of those bases. With a single materials station you can mix 4 materials in 1 print, and you can even combine stations for up to 16. And it's really, really, REALLT fast. The big hangup is its a closed ecosystem with their own slicer, black box firmware, most components have to be bought through Bambu, etc. But like Apple thats how they ensure it works well, by having control over everything.

Futbalfantic

Well-Known Member

- Joined

- Aug 5, 2006

- Location

- Charlotte

I’m super jealous. Want to buy one of those. $$$Super stoked about this father's day present.

Weeks of hints I was going to buy it anyway paid off.

View attachment 399122

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

It is a lot of money for a home device.I’m super jealous. Want to buy one of those. $$$

I'm hoping this is a "buy once, cry once" scenario instead of continuing to put $$ into upgrades... and I already have a potential opportunity to use it to make some $$ so it may balance out.

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

It's mind blowing how fast this thing is.

It will crank out a standard size Benchie boat model in about 20 minutes. The default max speed is 200mm/s.

It's also not quiet lol.

Random sample print

It will crank out a standard size Benchie boat model in about 20 minutes. The default max speed is 200mm/s.

It's also not quiet lol.

Random sample print

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

It's mostly a question of whether you want to direct extruder or the remote Bowden type.since prime is here and they are on sale, what is the recommendation for a crealty? 3 neo or maybe 3 s1?

Direct extruder give you more options for materials, and a little bit more direct upgrade pathway for fancy extruders or fancy hot ends.

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

Holy cow. Bambu Labs has released the new P1S. It's basically a P1p but with panels included.

That means that are for only 700 bucks you can get a machine capable of several different kinds of materials the prince fantastically, very fast, right out of the box. And it's only a thousand bucks if you get the material station with it.

That's going to crush the upper end basic home printer market.

That means that are for only 700 bucks you can get a machine capable of several different kinds of materials the prince fantastically, very fast, right out of the box. And it's only a thousand bucks if you get the material station with it.

That's going to crush the upper end basic home printer market.

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

FYI I've decided I have no need for the Mosquito Magnum and BondTech LGX extruder combo I got and never used, so they're up for sale on discount

Futbalfantic

Well-Known Member

- Joined

- Aug 5, 2006

- Location

- Charlotte

So what is going to be the difference between the XC1 and the P1S? Besides $700Holy cow. Bambu Labs has released the new P1S. It's basically a P1p but with panels included.

That means that are for only 700 bucks you can get a machine capable of several different kinds of materials the prince fantastically, very fast, right out of the box. And it's only a thousand bucks if you get the material station with it.

That's going to crush the upper end basic home printer market.

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

First of all the difference is really only about $500 because the material station is separate, but either one can use it.So what is going to be the difference between the XC1 and the P1S? Besides $700

But here's a comparison chart

Compare all 3D printers | Bambu Lab

Compare features and technical specifications for the Bambu Lab 3D printer lineup: H2C, P2S, H2D, H2S, X1C, X1E, P1S, A1, P1P, A1 mini.

Long and short of it is that the X1C has the premium version options of everything

Edit - good review here

Last edited:

mbalbritton

#@$%!

- Joined

- Mar 22, 2005

- Location

- Greensboro, NC

Our 3D Printer

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

Ah yes - looks like a BigRep One?

Something like a 1meter build volume, nozzles 0.6 to 2(!) MM.

The heaters on these things are really impressive.

mbalbritton

#@$%!

- Joined

- Mar 22, 2005

- Location

- Greensboro, NC

I don’t know. It was actually at our sister facility in London. I was impressed. It was one or many 3D printers they have. They even have a multi color resin printer that will 3D print eyes for Wax figures for our Madam Tussaud’s figures.Ah yes - looks like a BigRep One?

Something like a 1meter build volume, nozzles 0.6 to 2(!) MM.

The heaters on these things are really impressive.

I don’t know enough about this shit, just that we are looking at options for my facility now.

Tacoma747

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Winston-Salem

I'll start the bidding at one turdyFYI I've decided I have no need for the Mosquito Magnum and BondTech LGX extruder combo I got and never used, so they're up for sale on discount

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

You're welcome to, but there's a reserve minimum... I have a Bambu to pay offI'll start the bidding at one turdy

Tacoma747

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Winston-Salem

Anyone print the LW PLA? The foaming type (not pre-foamed). I bought a roll of it I want to try printing an RC plane.

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

I got a spool of it awhile ago, can't remember the brand name. Oh wait - it's TPU I think? Its really soft (like Shore A 35 or something) when you print at low temp but harder at high temp, so you can (theoretically) print a single "material" with different hardness.Anyone print the LW PLA? The foaming type (not pre-foamed). I bought a roll of it I want to try printing an RC plane.

I had a lot of troubling getting decent extrusion and adhesion at the lower foaming temp. Gave up and forgot about it. Been meaning to revisit it though bc Wifey needs a custom sole insert for her shoes.

I don't think thats what you're referring to though

Tacoma747

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Winston-Salem

I got a spool of it awhile ago, can't remember the brand name. Oh wait - it's TPU I think? Its really soft (like Shore A 35 or something) when you print at low temp but harder at high temp, so you can (theoretically) print a single "material" with different hardness.

I had a lot of troubling getting decent extrusion and adhesion at the lower foaming temp. Gave up and forgot about it. Been meaning to revisit it though bc Wifey needs a custom sole insert for her shoes.

I don't think thats what you're referring to though

No, LW (lightweight) PLA is hard like PLA. It foams at 230°+ and I think basically doubles in size. Therefore it can still be fairly strong but light (for single walled prints like would be required for airplanes).

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

The crossover everybody wants

Tacoma747

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Winston-Salem

So, LWPLA is very tricky to get to print right, I am still messing with it trying to get satisfactory results. This stuff definitely feels lighter, granted, I am printing single wall stuff as well so thats a first for me too. The printed pieces feel like paper/cloth. It doesn't feel like plastic at all, you can write on it with a pencil, its pretty weird. Will actually be great for an RC plane as it gives it that 'cloth covered' feel and look that a real airplane would have.

RatLabGuy

You look like a monkey and smell like one too

- Joined

- May 18, 2005

- Location

- Churchville, MD

If its that light - why single wall? I'd think you'd need more strengthSo, LWPLA is very tricky to get to print right, I am still messing with it trying to get satisfactory results. This stuff definitely feels lighter, granted, I am printing single wall stuff as well so thats a first for me too. The printed pieces feel like paper/cloth. It doesn't feel like plastic at all, you can write on it with a pencil, its pretty weird. Will actually be great for an RC plane as it gives it that 'cloth covered' feel and look that a real airplane would have.

Tacoma747

Well-Known Member

- Joined

- Mar 20, 2005

- Location

- Winston-Salem

If its that light - why single wall? I'd think you'd need more strength

Airplanes fly much better when they aren't heavy. A big problem printing single wall planes with PLA is weight, or so I hear, I haven't printed one yet.

I just want to figure out how to get the inner structure to not show through....