So I have been chipping away slowly at some progress. I blew apart the TPI fuel rails mentioned a few posts back. The ends of the rails were drilled and tapped to 1/2" NPT so I can later put adapter fittings in them. The crossover ports were drilled and tapped to 3/8" NPT. I really didn't need them to be there at all, so I used some fuel-safe adhesive sealant and plugged the holes with a 3/8" NPT plug made from aluminum bar stock. Just to complete the look, I milled everything flush...almost like they weren't even there....

I will disclose some rather...embarrassing...information. I sorta fucked up.

While admiring my handiwork, (more like looking at the inconsistent travel speed on the finish of the milled surface above...the ways on that mill are sticky as fawk...I mean, really?) I noticed that one of the ends that were drilled went a little too far...I drilled one hole a little too deep (ahem...that's what she said

).

The issue here lies in the close proximity of the end of the rail to an injector bung hole.

Yeah, I said it. Moving along.

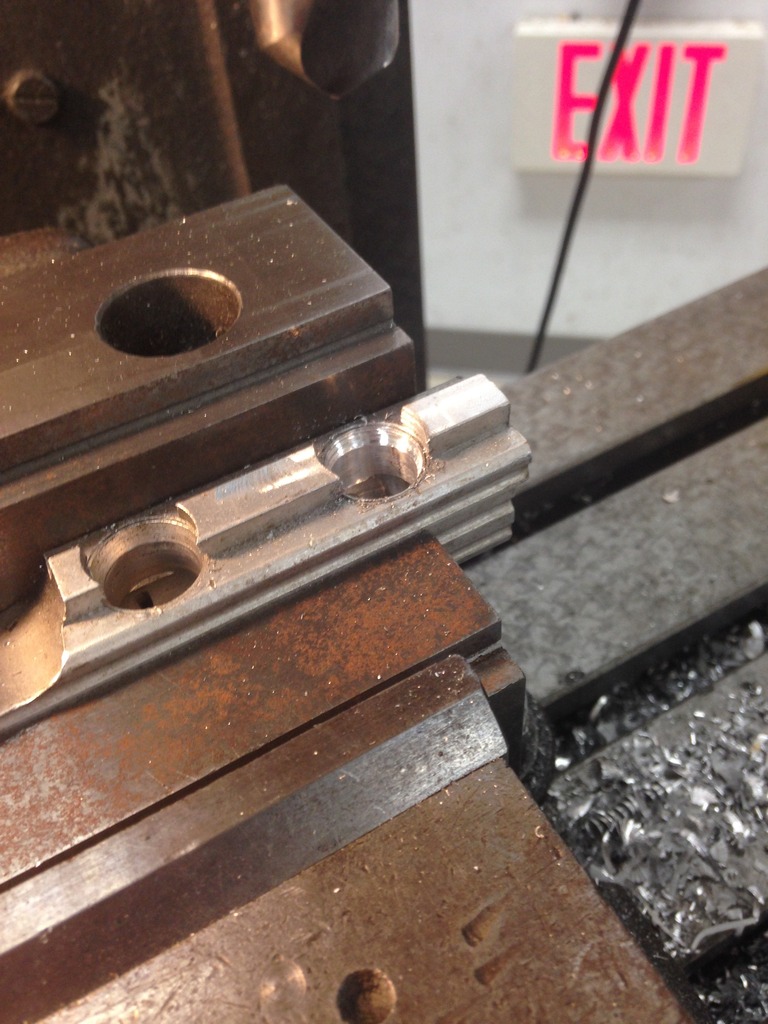

Visual aid shown here:

Look at the edge of the bung, toward the threaded hole on the end...this shows you a bit better.

Yeah, that hole got fucked up. Awesome.

Soooo...what to do...I reckon we're gonna fix it. I'm convinced that a repair will work just as good as the original hole. We do it to engines all the time, right?

So, I figured I'd use a similar method to how the crossover holes got plugged. I first was planning to use some .625 round stock, run some UNF threads down on it, and bore the ID to match the injector bung's original size. But once I consulted my handy-dandy Machinist's Handbook, I saw how close the minor diameter of 5/8" UNF thread was to the ID of the injector bung hole...it would have left something silly like ~.010" wall thickness at the minor diameter of the thread. That just didn't give me a warm and fuzzy. And .75" round stock was really too big, making the outside of the rail pretty thin.

So why not do it the same way as the crossover ports? That's exactly what I did. After aligning the fuel rail on the mill, which was a bitch to get it perfectly level and square to the mill travel...I drilled the injector bung out to 37/64" to be tapped to 3/8" NPT. I made another plug, making sure that it would have adequate thread engagement 1) to be tight enough and 2) to be deep enough to seat the injector. Then I tightened the plug in place with a dab of the same fuel-safe adhesive.

Still a little scared here...I started milling off the excess material. Then found that luckily a 5/8" end mill would plunge cut the plug and fit the inside of the countersink/grooves where the injector retainer clip goes.

Beginning to look promising, because It's starting to look like the other holes again...sorta. Found the appropriate drill and reamer size, then countersunk the injector lead-in. Ta-da!

It sorta almost looks exactly like the rest of them. Now if I didn't dork up that hole in the first place, I would have been that much more ahead.

I figured it couldn't hurt to clean these nasty things up some...

So that's all my progress for now. I've got a set of injectors on the way, and my next job will be to yank the intake manifold if I can get 5 minutes spare time if the temperature outside ever gets back up near freezing. Not doing it in single digits with sub-zero wind chills...fawk that noise. I'll punch some holes in the intake, and install those injector bungs I made a while back. Baby steps...

).

). Yeah, I said it. Moving along.

Yeah, I said it. Moving along.