ol'Jeeps

Dirty Jeeps...Done Dirt Cheap!

- Joined

- Dec 5, 2006

- Location

- Hickory, NC

...

Matt

I like how when it folds down it can light the underside!

Great for those night trail repairs!

...

Matt

If you were using higher amps the green would show it's drawback. Green was the "OG".All the research I've done says no green tungsten for alum on inverter machines. Only green on transformer style units. But I swear the green worked great on my diversion, except for the lap joint, red and grey worked better there. The ball on the green didn't seem to spread the heat as well on a lap, but the red and grey kept a nice point which seemed to help in that position. Imma keep on practicing ...

Didn't have any lathanated at ARC3 today, or I would have run it through also.

Matt

Copy away my friend...that's where we all get ideas from.I am going to essentially copy your front bumper and grille guard on my Ranger. My boner bar is soooo 2005!

Call it flattery my friend!

Yes it is. I'm glad I've been prepping steel so thoroughly all this time, it doesn't make aluminum feel like that much more work, lol.Aluminum is fun isn't it?

I'm glad as hell I took that jump to try it.

Your work is second to none!

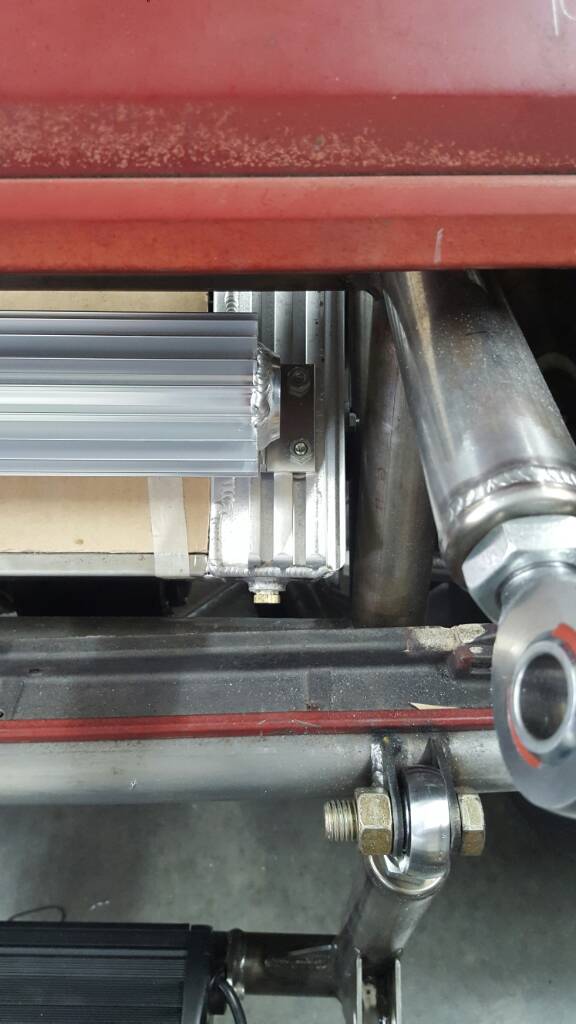

Yea, no kidding.I like that you can't see the motor when you open the hood.

It's kinda like a Super Duty...

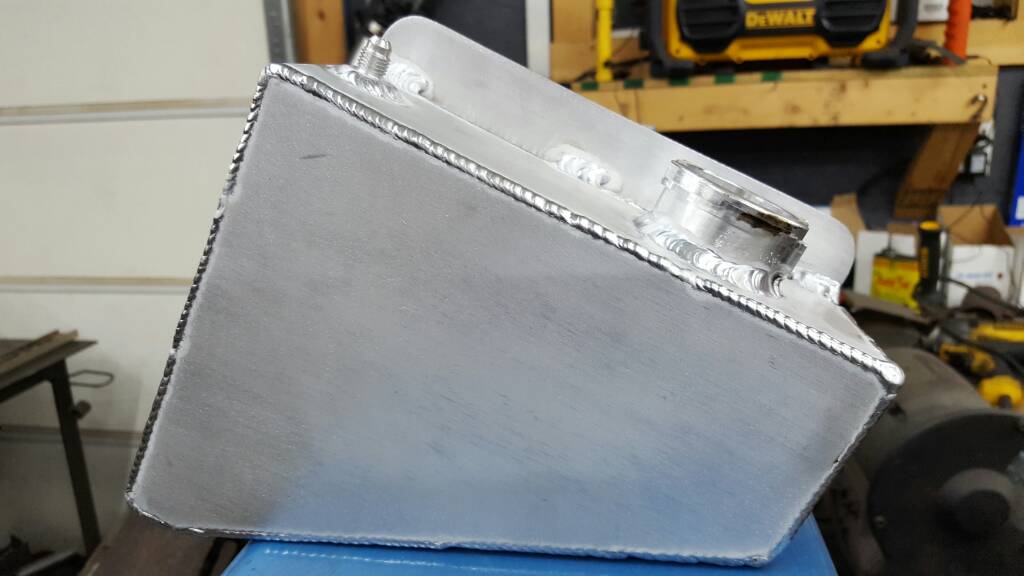

Matt I'd have to agree with you tig welding aluminum is not as bad as I thought it was going to be. To me it is easier than tig welding steel as long as you have a good rhythm. But all your welds seem to be perfect I would guess you did a lot of practice beads before you ventured into making your reservoirs. I know I'm in school for it and I'm not as skilled as you and many others but that's why I'm inn school for it since I can not work I hope to one day do little side jobs at my own pace and it turn out as good as your work along with many others. Keep up the good work Matt. I show off your work to my instructors All the time and they have never had a bad thing to say about it all they say is he's a true professional.

Matt I'd have to agree with you tig welding aluminum is not as bad as I thought it was going to be. To me it is easier than tig welding steel as long as you have a good rhythm. But all your welds seem to be perfect I would guess you did a lot of practice beads before you ventured into making your reservoirs. I know I'm in school for it and I'm not as skilled as you and many others but that's why I'm inn school for it since I can not work I hope to one day do little side jobs at my own pace and it turn out as good as your work along with many others. Keep up the good work Matt. I show off your work to my instructors All the time and they have never had a bad thing to say about it all they say is he's a true professional.

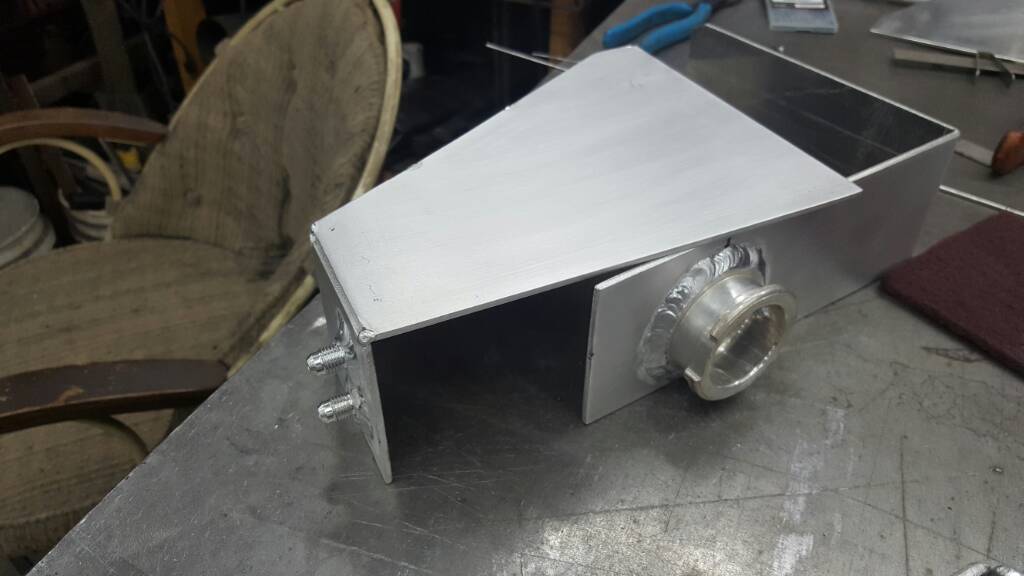

Thanks guys. I'm really having fun with it. I wish I had picked up a tig torch 15-20 years ago. So far I have about 12-15 hours behind the hood with the torch, (and 2 bottles of gas- had the gas turned too high on the first bottle at 20-25 cfm, now I'm running 12-15.) I tend to jump right in on a task and screw up, but also learn how to repair those mistakes, as I go. These aren't perfect, but I will enjoy making the second versions of them at a later date. I have an aluminum spool gun also, and the first arc I struck with it,17 years ago, was building a 20 gal aluminum fuel cell, (on the cab truck I posted earlier), boy did I really have to learn how to repair on that piece, [emoji90] [emoji33]- Btw I haven't used it since on aluminum... I still have much to learn!Never truer words

ThanksLooking good!

Where did you source the mesh from?