adamk

Well-Known Member

- Joined

- Nov 20, 2010

- Location

- Hot-As-Hell, TX

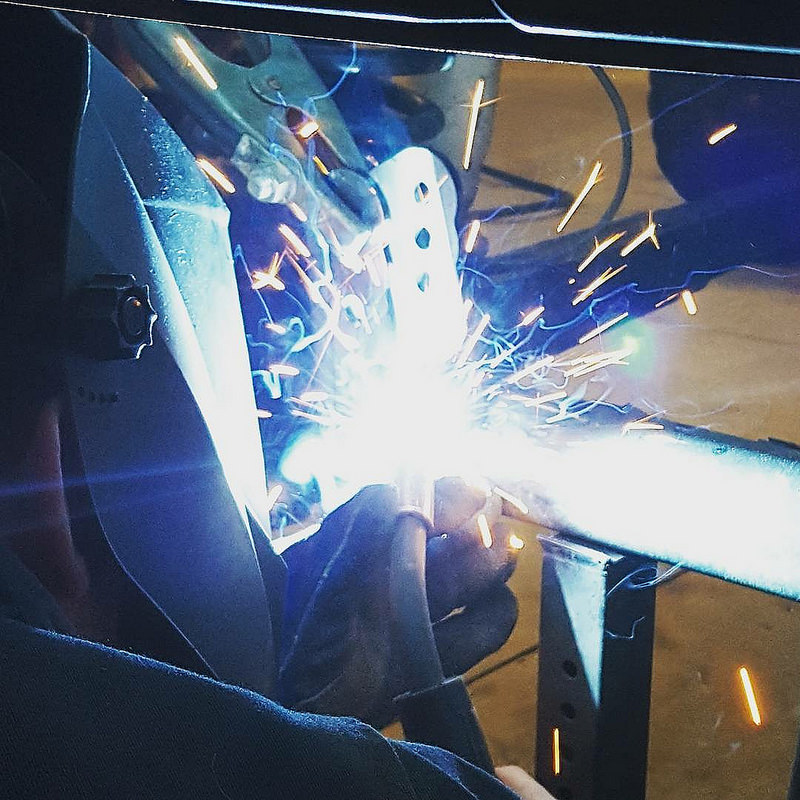

This past Saturday I stripped down the front axle to replace the ball joints and install a Reid knuckle for high steer. A new axle side track bar mount will be going on as well.

Incase you are wondering Adam I think that RE track bar is 3/16 wall. If you want me to check I have a scrap piece from when I cut mine apart.

Sent from my iPhone using Tapatalk

Fairly certain we have enough tube to make a track bar. I vote sell it.I'm not 100% sure if I'm going to use/cut it down or just make a whole new one and sell it. It's funny how much these things are now. I can sell it used for more than I paid for it new.

The track bar is pretty short (27.5") but it fits. It's also not perfectly parallel to the drag link but it's closer than it was. It's right at 2.5 degrees off from the drag link.

Why did you mount your ram to the knuckle? All of the hydro assist setups I've seen had the ram mount to the tie-rod. Also looks like you've got heims on your tie rod but TRES on your draglink Pros/Cons to your way? Gathering parts for my hydro assist build and just looking for options.

Have you looked at trying to get the Trac bar to the knuckle C? I don’t know what the cross section view of you axle looks like but I’ve seen a few people pull it off. If I can keep my coils back I am definitely going to try.

At the time that I installed the ram, I had very little room. It would have contacted the old track bar if I turned it around and mounted it to the tie rod. I will be redoing it in the near future now that I have more room to work with. As for the TRE/Heim...My old drag link angle would kill heim joints very quickly. I got tired of replacing them 2-3 times a year. Also, the high angle TRE allows for more travel than the 7/8 joint with 3/4 bolt. I started with just adding a TRE at the pitman arm and then when I went high steer I added the TRE to the knuckle.

I'm running 1ton TREs on both the draglink and the tie-rod with hi-steer knuckles. I'm assuming you mounted the ram off the diff cover? Any issues with the ram mounted directly to the knuckle? I have plenty of room under mine right now so I can place it on either the knuckle or the tie-rod. After seeing your setup, I think I could run a mount off the axle tube(pass side drop for me) and then run it straight to the knuckle.

Did you weld the door shut?

Those a-pillars turned out great

Any updates on this thing?

Sent from my iPhone using Tapatalk

Any updates on this thing?

Sent from my iPhone using Tapatalk