MetalCraftSolved

Well-Known Member

- Joined

- Jun 20, 2010

- Location

- NC

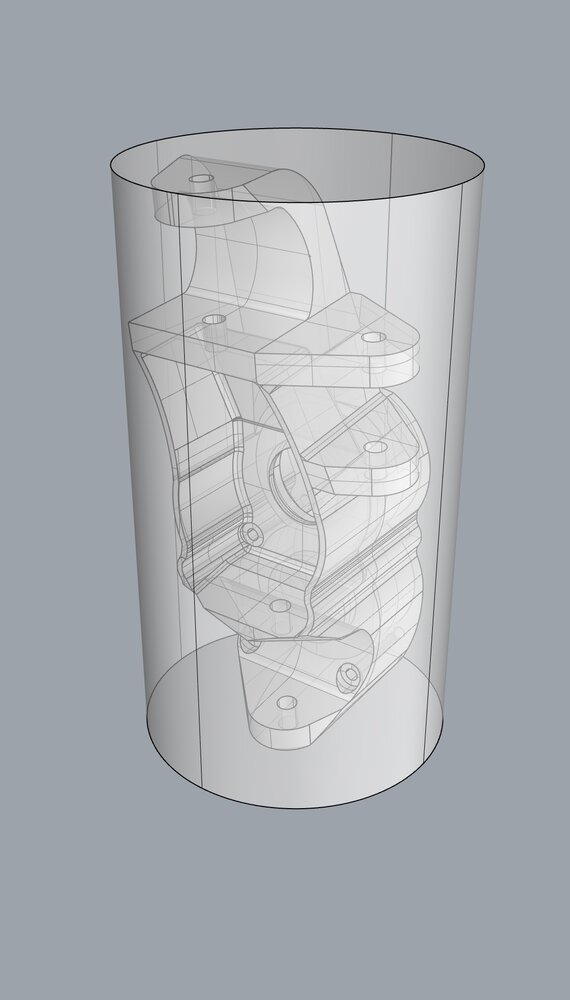

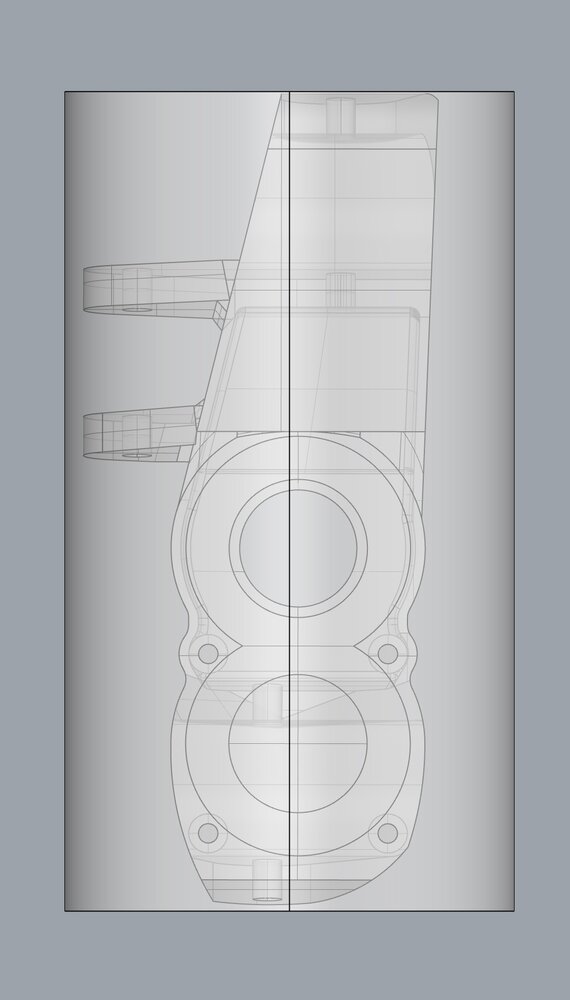

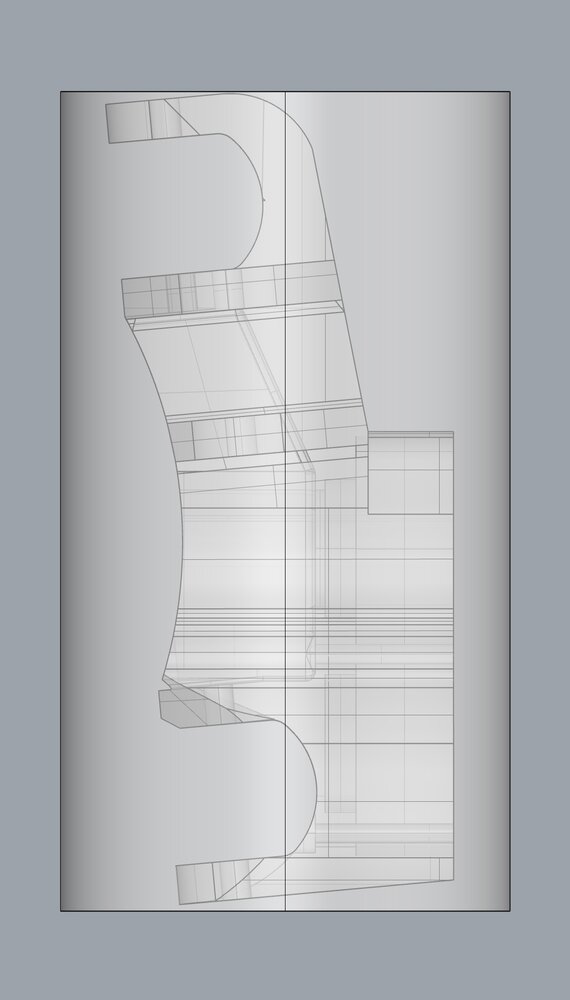

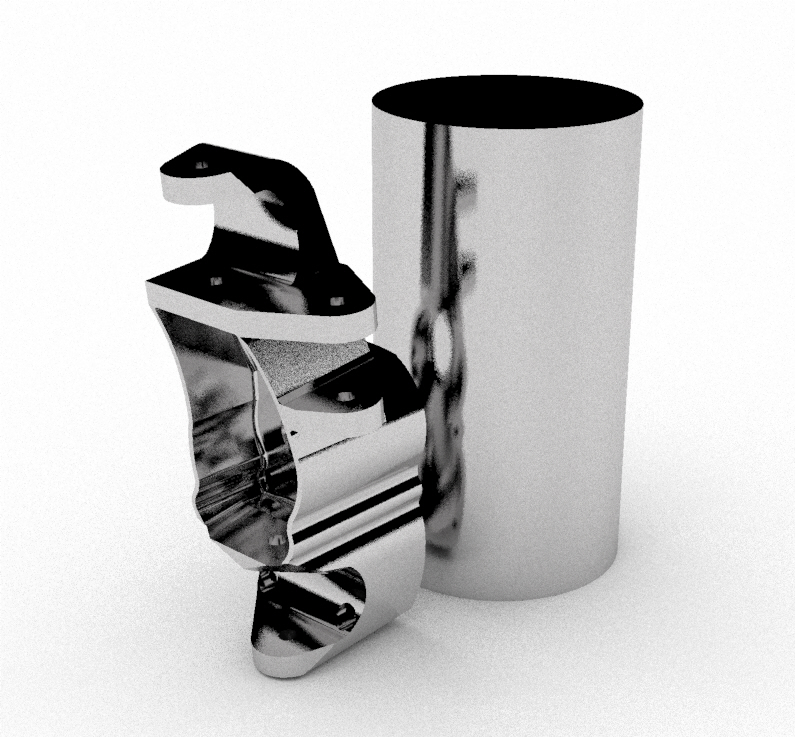

I can mill my knuckle from 21 inch tall, 11.5 inch round stock 7075 aluminum on the 5 axis machine I saw today. Also means I can get down to the nitty gritty on the detail.

I truly wish you the best of luck, but I'm also confident you honestly have no idea what it would cost to have a pair of those made (even assuming a zero scrap rate). Maybe someone in the engineering and machining world could give you better advice.I can mill my knuckle from 21 inch tall, 11.5 inch round stock 7075 aluminum on the 5 axis machine I saw today. Also means I can get down to the nitty gritty on the detail.

View attachment 354053

View attachment 354054

View attachment 354055

View attachment 354056

I truly wish you the best of luck, but I'm also confident you honestly have no idea what it would cost to have a pair of those made (even assuming a zero scrap rate). Maybe someone in the engineering and machining world could give you better advice.

I just want to know what a chunk of AL like that cost much less the machine work.....

So basically $15k a knuckle after machining.

Nah, it wouldn't be that bad. But $10k a pair isn't unreasonable to expect. And they are aluminum, with little concern for torsional rigidity, so you better have a backup pair. I already see where the first crack will start.So basically $15k a knuckle after machining.

Psh. Torsional schmorsional. You worry too much.Nah, it wouldn't be that bad. But $10k a pair isn't unreasonable to expect. And they are aluminum, with little concern for torsional rigidity, so you better have a backup pair. I already see where the first crack will start.

What, you think you're an engineer or something?

What, you think you're an engineer or something?

That's probably 1500-2500 low. What's wrong with a fabricated knuckle? If you have any work into after machining and want to make any money off them they gonna be 7500 a piece. The front end alone cost more than some entire race buggies

I'd bet there's plenty of 5axis capability around and it's a cool part. Just complicated and time consuming.I'd like to feel like I'm pretty big into doing the whole "interact with the people around you thing." I've sent the knuckle demo file to 5 places in the immediate area. (North Carolina) I received a quick response from 1 that said they were looking forward to looking at it tomorrow, when they get to work. Hopefully I'll hear from all of them by the end of the week. I would bet that there is 5-axis equipment around that I don't know about. It's just one of those things, where I'd enjoy paying some attention to prideful work coming out of NC.

I'd bet there's plenty of 5axis capability around and it's a cool part. Just complicated and time consuming.

With no design changes, it will probably be more than that.$3k for a 18"x18" skid? put me down for 3