Not disagreeing, but curious how it could be leftover if the whole motor was torn apart when it was built. Where could the needle bearings have been hiding?

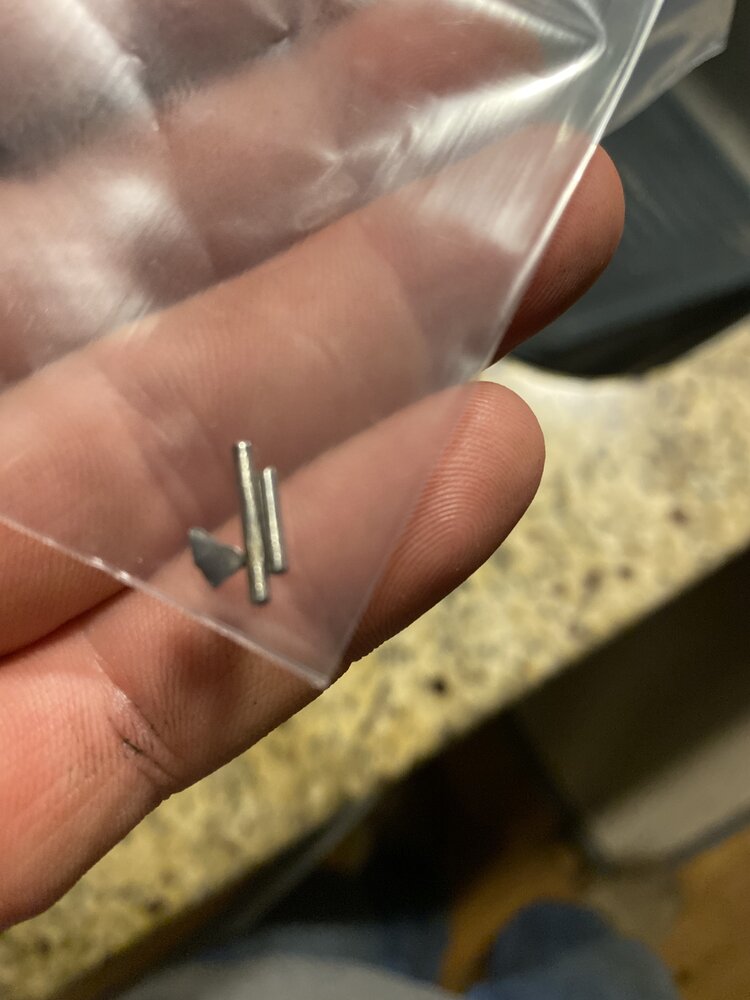

If the block was tanked, but they didn't blow out all the oil passages. Could have been hiding somewhere in the heads. Possibly even already in the oil pan. There's lot of little places it could have sat and been completely out of the way, but the dislodged during assembly or after running it for a while once oil pressure flushed it out. There's no telling. For one of those to have come out now...the lifter axle would have had to have come out or the wheel would be worn in half. He'd have certainly seen lots of metal flake during the oil change, a super fuzzy drain plug magnet, certainly have heard some noises, and likely felt a noticeable loss in power. Or it would have at least been running kinda funny.

Care to elaborate? I personally wouldn’t hesitate to shop at either, but I’m always willing to learn from others experience.

Had some dealings with

Tooley. Seen a handful of "his" broken valve springs. Lots of recommendations for dual valve springs when it's not needed. Lackluster cam designs and specs. Plus rebranding of other various parts as his own or having a cheaper version of a well known part made and marketed as the same or better, All in all, you can generally get the same thing he sells or something better somewhere else. He's got marketing down, along with Texas Speed, and I guess that's why so many people get stuff from there. I'm of the mindset that the extra 50-100 bucks is totally worth it to me if I'm going through the work and expense of putting a cam in something and getting a setup that's been designed to run with what I have to net the results I want. Not just something that's sorta close. Texas Speed was in the game of guessing for a long time and grinding a lot of cams, but just changing something like lobe separation angle a degree or two. They'd let customers be their guinea pigs, for lack of a better term. I did try to warn a buddy of mine on the west coast not to buy a long block from them. Alas, he did, and not a cheap one. It was a bored/stroked LS2 which wound up at something like 402 ci. It never would make the kind of power it was supposed to, starting dropping oil pressure, spun a rod bearing, and upon disassembly was found to have 3 different brands of cam bearings in it (that also measured different inside diameters), and mismatched rod bearings. They wouldn't give him any money back or make things right with him on the premise that he disassembled it. Who wouldn't in that situation? I think they were rump ruffled that he caught them selling high dollar stuff with subpar workmanship.

If they've got stuff on the shelf that nobody else seems to have, I'll buy it as long as it's not internal engine parts. So far I haven't needed to though. Between Rock Auto, Summit, Scoggins Dickey, or any other number of places I've always been able to find what I needed.

Aside from any of that, I have noticed that Comp's trunion upgrade hasn't been all that great. I've seem some of the rollers are appearing to wear through the case hardening on the rocker shaft itself. I'm going to try out the CHE bushing style rocker setup as soon as I get around to it. I'm not sure if I got a set that didn't get heat treated properly or what. I'll investigate further once I disassemble them.