FSU Off-Road

Well-Known Member

- Joined

- Feb 4, 2018

- Location

- Hickory, NC

Ok, the biggest update to date!

As noted, there is a lot going on with the car right now. When we got back to NC, there was no rush on getting the car unloaded; we knew there was a lot of work to be done in order to get it ready again. Knowing we weren't going to race Nationals, all of our focus has been on improvements, fixing the knowns, and preparing for KOH24. We've had a couple of work weekends with the car now and have solutions for each.

First things first, we needed to go over the car and see what all was damaged and inspect everything closely. Thankfully we had a few guys come help with this, which made disassembly of the car much easier.

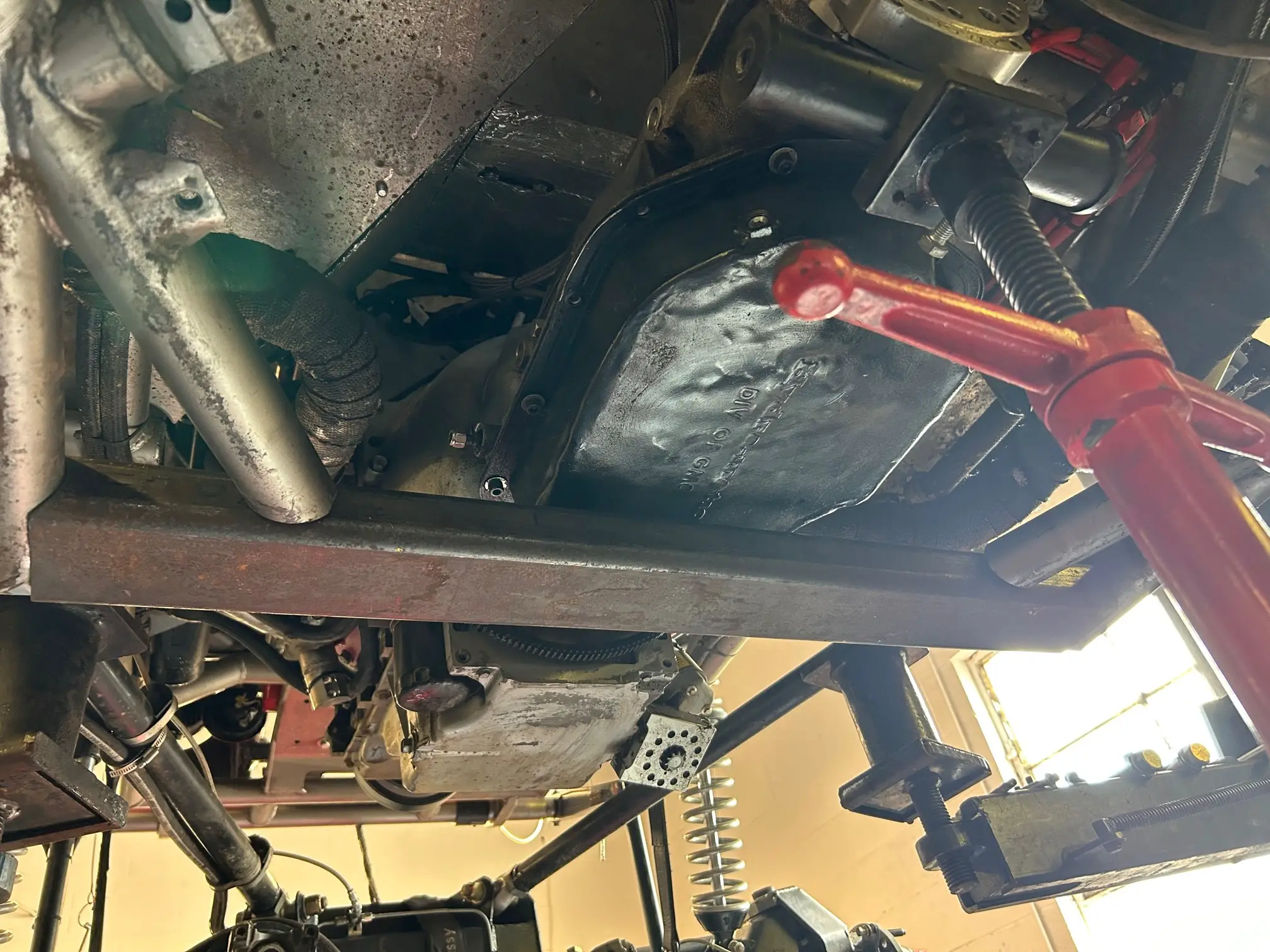

As you may have noticed, while disassembling the powertrain, we went ahead and cut out the mangled crossover tube. Made for an easier disassembly. We already knew this was going to be something we did as we needed to beef this crossover tube up for the future. The goal is to utilize 1/4" rectangle tubing in its place to add strength and protect everything in the future. You can see the overall idea below and to make sure everything would fit, we went ahead and put the transmission back in to verify.

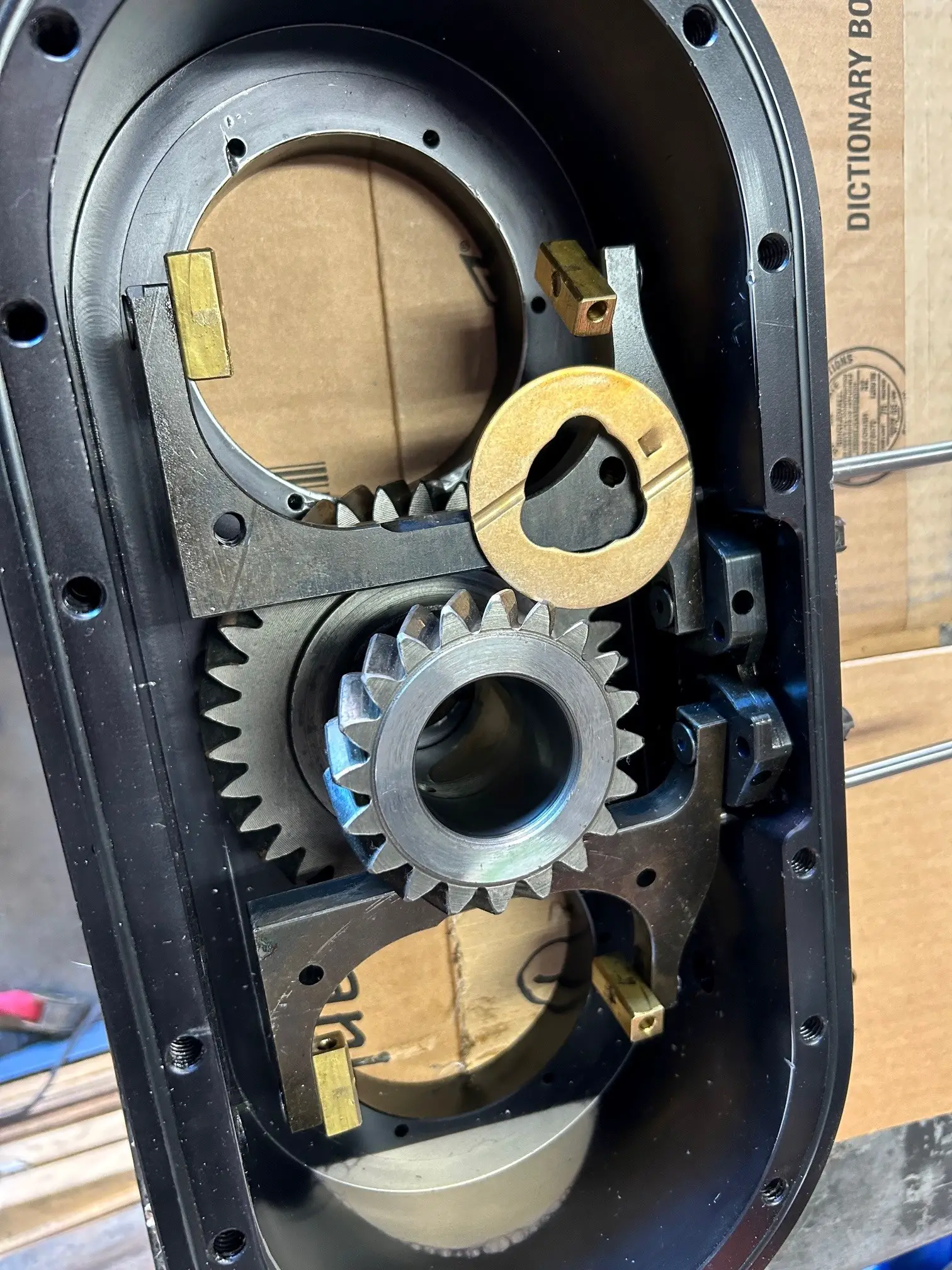

Again, it's close to the pan, just as the original tube was, however I had some ideas to make this work better for us. With a solution to fix the crossover tube, we disassembled the Colossus case to see what went wrong. Didn't take long to see that the D300 gears didn't hold up to the abuse from Crandon. All of the front gears were broken, leaving us with only 2wd. So, I searched the good old marketplace for some spares. Luckily, I was able to find a replacement D300 with a spare set of gears and rebuilt the case after a good cleaning and thorough inspection.

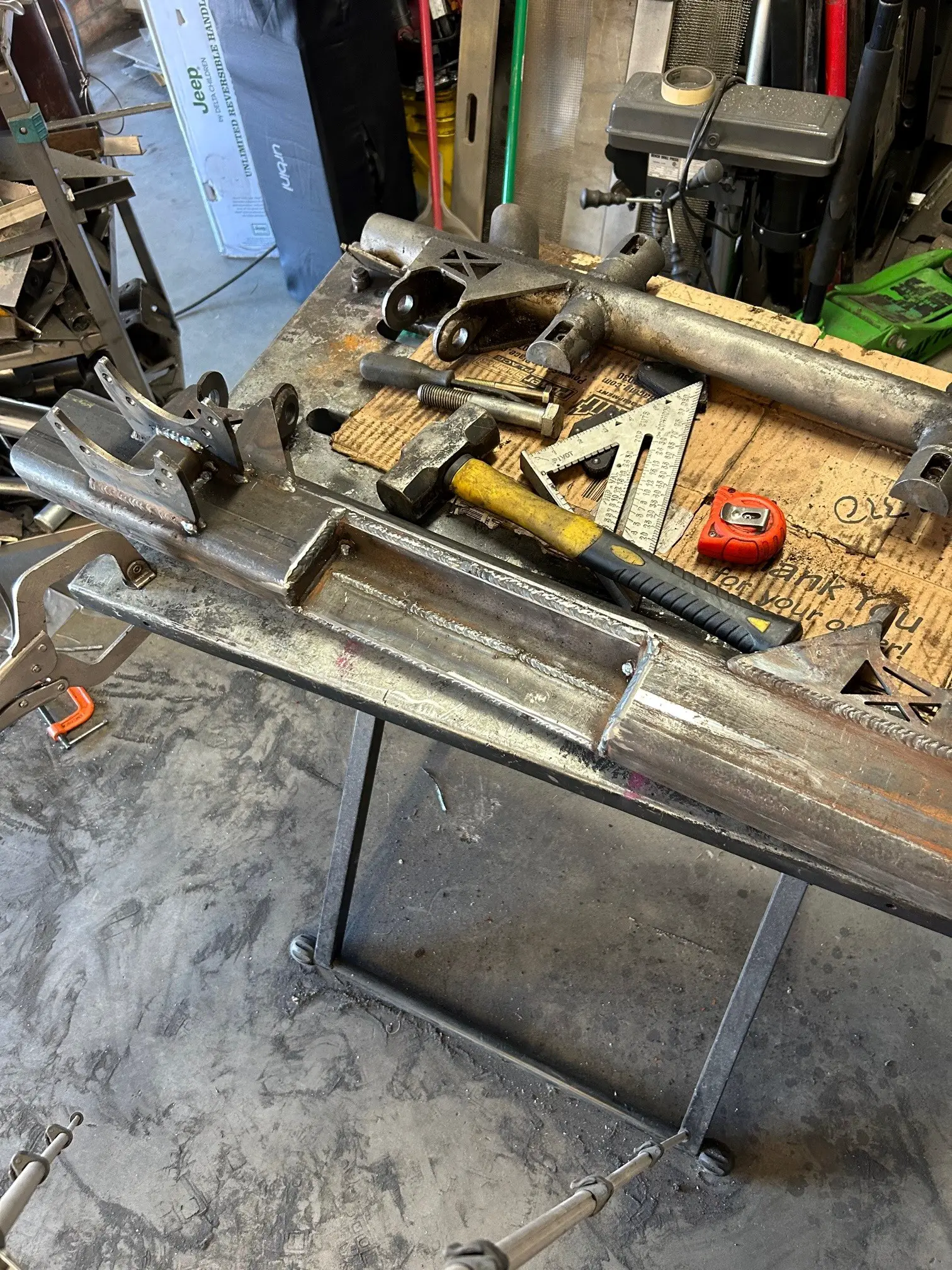

After the rebuild, I focused on the crossover tube again. In order to create a little space, I notched the rectangular tube for the trans pan. This will allow us some extra space for removing the pan if needed in the future as well as running into the same clearance issue. Not only did the notch help with clearance, but I was also able to internally gusset this area as well making for a stronger center section. With a couple of scrap pieces, I was able to close it all back up and get it ready for the link mounts and carrier bearing mount. I reused some old link mounts for the front, grinding away a little material for them to set flush on the rectangular tube versus round tube. As for the carrier bearing mount, the original design was based off two separate round tubes, with the rectangular tube, I was able to put both mounts on this crossover tube. This allowed me to have a better gusset in between making this mount much stronger to any loads. The only thing I need to add are the tube clamps for the skid plates.

All we have to do now is install the crossover tube and get it welded in place and we'll be good to go! Nope, not even close lol.

Now as for the other knowns and issues, we have the following that we are addressing and will need to take care of before KOH!

1. Transmission pan: With the old beaten and bent steel pan (leaked like crazy), we do have a new pan to install. However, we need to re-tap a few bolt holes in order to install the new pan. This was an issue when we installed the pan at Crandon. Simple fix, but still pressing.

2. Belly Pan Height: Unfortunately, this falls on me as I designed the ride height with 40's not 37's. Therefore, the belly sits a little lower than we want. Worked well for Crandon and the short course, however we want to add a couple of inches for the other races. This will also help us with a couple of other issues with max up-travel. Killing two birds I suppose but is going to take some time to redo the suspension.

3. Colossus D300 Case: Although we upgraded everything internally with 32 splines shafts, the gears themselves are not going to hold up. We could convert the gears to JB Conversions 4:1, however we do not need that gearing. Therefore, the D300 is out! We are now going with the Colossus NP205 (I've created a good relationship with Behemoth, and JB Conversions). We will be utilizing the new 3:1 from JB Conversions within the 205 case. All will be here December for install. Until then, we'll put the D300 back in for mobility purposes.

4. Coilovers: As you all are aware, our 2.5" coilovers are not exactly the "go to" when it comes to racing applications with single shocks per corner. They do have adjusters and worked well (I still recommend), but for the longer races and high speeds we would benefit from IBP's more. With that said, I was able to source some 3" IBP's from Fox. With the larger diameter springs, we are going to run into some clearance issues on the chassis I believe. I assume we'll be doing some more tube notching for the 3" IBP's to fit. With that said, they are a little longer than our 2.5", so we're hoping we will be able to utilize the existing mounts without any drastic changes to the mount locations giving us our additional belly height. Fingers crossed. But we will still have to change bump locations and limit strap lengths regardless.

5. Links: With the 2" lowers bananad after one race, I can only image what more races would do. In order to save the chassis alignments, I reached out to Tim at TMR Customs for their new aluminum links. Other than the rear trailing arms, we now have a full set of aluminum links on the way for both the front and the rear.

6. Spare tire carrier: As some of you pointed out, the small material on the tire carrier didn't hold up. Not a problem moving forward. We are now designing a new tire carrier that will not swivel down; however, it will be removable by utilizing tube clamps. It will be more structurally sound and allow us to build a few areas for spares and tools, which is our next big hurdle.

7. With all that KOH brings to the table, spare parts, tools, a jack, etc. are essential! To date, we don't have any of this stuff addressed. We have some good ideas on spares and a tool bag, but we need some more time to figure it all out. This is something we will be working on after we address the other issues.

8. Misc things: There are a few additional things we need to add and fix before KOH. Rock lights, a few Holley adjustments, transmission temp sensor fixed, things like that. Not super pressing, but things we do need for KOH.

YES, I know... it's a lot to address in a little timeframe. Don't remind me! But I assure you, we'll knock it out! KOH 2024 here we come!

Cheers!

As noted, there is a lot going on with the car right now. When we got back to NC, there was no rush on getting the car unloaded; we knew there was a lot of work to be done in order to get it ready again. Knowing we weren't going to race Nationals, all of our focus has been on improvements, fixing the knowns, and preparing for KOH24. We've had a couple of work weekends with the car now and have solutions for each.

First things first, we needed to go over the car and see what all was damaged and inspect everything closely. Thankfully we had a few guys come help with this, which made disassembly of the car much easier.

As you may have noticed, while disassembling the powertrain, we went ahead and cut out the mangled crossover tube. Made for an easier disassembly. We already knew this was going to be something we did as we needed to beef this crossover tube up for the future. The goal is to utilize 1/4" rectangle tubing in its place to add strength and protect everything in the future. You can see the overall idea below and to make sure everything would fit, we went ahead and put the transmission back in to verify.

Again, it's close to the pan, just as the original tube was, however I had some ideas to make this work better for us. With a solution to fix the crossover tube, we disassembled the Colossus case to see what went wrong. Didn't take long to see that the D300 gears didn't hold up to the abuse from Crandon. All of the front gears were broken, leaving us with only 2wd. So, I searched the good old marketplace for some spares. Luckily, I was able to find a replacement D300 with a spare set of gears and rebuilt the case after a good cleaning and thorough inspection.

After the rebuild, I focused on the crossover tube again. In order to create a little space, I notched the rectangular tube for the trans pan. This will allow us some extra space for removing the pan if needed in the future as well as running into the same clearance issue. Not only did the notch help with clearance, but I was also able to internally gusset this area as well making for a stronger center section. With a couple of scrap pieces, I was able to close it all back up and get it ready for the link mounts and carrier bearing mount. I reused some old link mounts for the front, grinding away a little material for them to set flush on the rectangular tube versus round tube. As for the carrier bearing mount, the original design was based off two separate round tubes, with the rectangular tube, I was able to put both mounts on this crossover tube. This allowed me to have a better gusset in between making this mount much stronger to any loads. The only thing I need to add are the tube clamps for the skid plates.

All we have to do now is install the crossover tube and get it welded in place and we'll be good to go! Nope, not even close lol.

Now as for the other knowns and issues, we have the following that we are addressing and will need to take care of before KOH!

1. Transmission pan: With the old beaten and bent steel pan (leaked like crazy), we do have a new pan to install. However, we need to re-tap a few bolt holes in order to install the new pan. This was an issue when we installed the pan at Crandon. Simple fix, but still pressing.

2. Belly Pan Height: Unfortunately, this falls on me as I designed the ride height with 40's not 37's. Therefore, the belly sits a little lower than we want. Worked well for Crandon and the short course, however we want to add a couple of inches for the other races. This will also help us with a couple of other issues with max up-travel. Killing two birds I suppose but is going to take some time to redo the suspension.

3. Colossus D300 Case: Although we upgraded everything internally with 32 splines shafts, the gears themselves are not going to hold up. We could convert the gears to JB Conversions 4:1, however we do not need that gearing. Therefore, the D300 is out! We are now going with the Colossus NP205 (I've created a good relationship with Behemoth, and JB Conversions). We will be utilizing the new 3:1 from JB Conversions within the 205 case. All will be here December for install. Until then, we'll put the D300 back in for mobility purposes.

4. Coilovers: As you all are aware, our 2.5" coilovers are not exactly the "go to" when it comes to racing applications with single shocks per corner. They do have adjusters and worked well (I still recommend), but for the longer races and high speeds we would benefit from IBP's more. With that said, I was able to source some 3" IBP's from Fox. With the larger diameter springs, we are going to run into some clearance issues on the chassis I believe. I assume we'll be doing some more tube notching for the 3" IBP's to fit. With that said, they are a little longer than our 2.5", so we're hoping we will be able to utilize the existing mounts without any drastic changes to the mount locations giving us our additional belly height. Fingers crossed. But we will still have to change bump locations and limit strap lengths regardless.

5. Links: With the 2" lowers bananad after one race, I can only image what more races would do. In order to save the chassis alignments, I reached out to Tim at TMR Customs for their new aluminum links. Other than the rear trailing arms, we now have a full set of aluminum links on the way for both the front and the rear.

6. Spare tire carrier: As some of you pointed out, the small material on the tire carrier didn't hold up. Not a problem moving forward. We are now designing a new tire carrier that will not swivel down; however, it will be removable by utilizing tube clamps. It will be more structurally sound and allow us to build a few areas for spares and tools, which is our next big hurdle.

7. With all that KOH brings to the table, spare parts, tools, a jack, etc. are essential! To date, we don't have any of this stuff addressed. We have some good ideas on spares and a tool bag, but we need some more time to figure it all out. This is something we will be working on after we address the other issues.

8. Misc things: There are a few additional things we need to add and fix before KOH. Rock lights, a few Holley adjustments, transmission temp sensor fixed, things like that. Not super pressing, but things we do need for KOH.

YES, I know... it's a lot to address in a little timeframe. Don't remind me! But I assure you, we'll knock it out! KOH 2024 here we come!

Cheers!