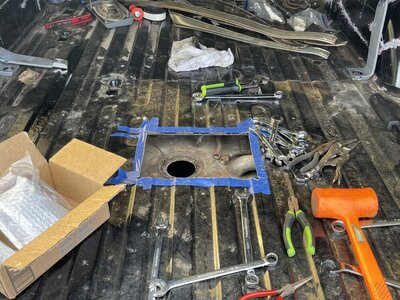

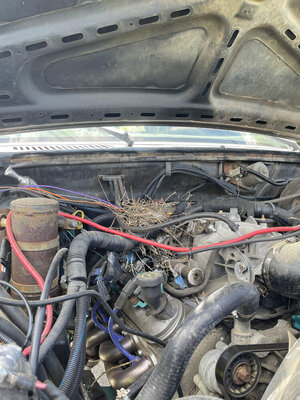

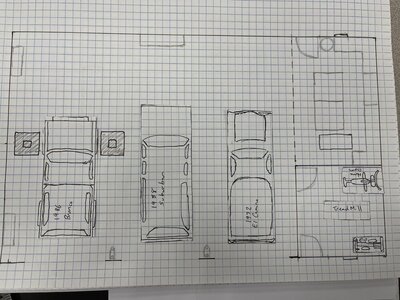

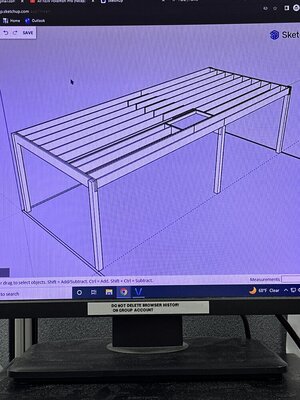

Went and picked up another project this week. My mom's old 88 suburban. It's sat for the better part of 10 years ever since it was parked with a busted radiator and a blown headgasket on the 350 (that was repaired with head gasket in a bottle). Some rust but nothing too terrible so far, rockers and rear quarters. The inside is a mess though. Planning a nice winter cruiser, no lift, some 32 inch tires. If I can't get the engine to run with a little work I will probably end up LS swapping it before I dump too much money in it. First thing will be to get it all cleaned up and assess everything.

Attachments

-

IMG_1910.jpeg295.7 KB · Views: 261

IMG_1910.jpeg295.7 KB · Views: 261 -

IMG_1919.jpeg245.3 KB · Views: 265

IMG_1919.jpeg245.3 KB · Views: 265 -

IMG_1918.jpeg234.8 KB · Views: 264

IMG_1918.jpeg234.8 KB · Views: 264 -

IMG_1917.jpeg229.9 KB · Views: 269

IMG_1917.jpeg229.9 KB · Views: 269 -

IMG_1915.jpeg193.6 KB · Views: 244

IMG_1915.jpeg193.6 KB · Views: 244 -

IMG_1914.jpeg146.1 KB · Views: 258

IMG_1914.jpeg146.1 KB · Views: 258 -

IMG_1913.jpeg159.1 KB · Views: 258

IMG_1913.jpeg159.1 KB · Views: 258 -

IMG_1920.jpeg204.2 KB · Views: 277

IMG_1920.jpeg204.2 KB · Views: 277 -

IMG_1916.jpeg222.3 KB · Views: 265

IMG_1916.jpeg222.3 KB · Views: 265 -

66007075608__7D963736-22DD-4B55-88B3-45BE0DEF127B.jpeg247.8 KB · Views: 260

66007075608__7D963736-22DD-4B55-88B3-45BE0DEF127B.jpeg247.8 KB · Views: 260