You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project Steampunk Vol.2

- Thread starter XJsavage

- Start date

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

Steve n Seagull?

I have that same album which also has the Nightwish cover on it.

It's hard to outdo symphonic/operatic metal, but a bluegrass band is nothing to play with.

Alright, gigs up... I'm a music nerd.

I have that same album which also has the Nightwish cover on it.

It's hard to outdo symphonic/operatic metal, but a bluegrass band is nothing to play with.

Alright, gigs up... I'm a music nerd.

It’s cool man me too.

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

A sufficient rear driveshaft just got moved up on my list. I knew from the start that a Spicer 1310-1330 wouldn't last long, especially with 4.56 gears and the aggressiveness of a Yukon Grizzly locker. Pair that with a peppy 5.3 litre and a bulletproof 42 year old manual transmission.... BI-YYYYOWWWWW!!!! (Crunch, grind...FML) Drag racing that squat truck had nothing to do with it.

Coast, did I to a halt in a moderately safe traffic-free spot, jumped out with a 5/16 wrench in hand, pulled the rear driveshaft bolts to the T-case yoke, threw the rear shaft in the cargo area and skeeted back home in 4-hi glory.

Yee. Yee.

Spare parts for the win. I fully intend to take the boat out with my dad to enjoy a weekend in the swamp.

The LS Jeep life ain't no BS.

Coast, did I to a halt in a moderately safe traffic-free spot, jumped out with a 5/16 wrench in hand, pulled the rear driveshaft bolts to the T-case yoke, threw the rear shaft in the cargo area and skeeted back home in 4-hi glory.

Yee. Yee.

Spare parts for the win. I fully intend to take the boat out with my dad to enjoy a weekend in the swamp.

The LS Jeep life ain't no BS.

Last edited:

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

Sums up my weekend. Repaired the driveshaft with some pieces parts from several driveshafts I got from @ghost a few years ago. I finished it up last night around 9:30. I really need to get some good shafts made. 1350 minimum. I rather not worry about things like that. Besides, I've got too many years, too many miles, and way too many trails to conquer in this Jeep.

My dad is with me today. Since my boating privelages are suspended until March 2021, he'll be riding with me a lot. Towing a jon boat to the river with a V8 Jeep is something he knows all too well. He became a hardcore Jeeper back in '76 when he retired from the USCG. He paid cash for a brand new 304 powered Golden Eagle and was exploring Harmon Den, Hurricane creek, Bumpass Cove before most of us were even born. He also mapped a majority of the CoWaSee back when most were afraid to explore it.

The OG river rat.

ghost

Well-Known Member

- Joined

- May 25, 2006

- Location

- Hartsville/Camden,SC

Nice. Ask him if he's familiar with Squadron 1.... Glad those parts laying around taking up space could help you my friend.

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

How often do you get down towards Orangeburg? And what are you doing Saturday? There's a gnarly junkyard you've probably never been to calling your name.Nice. Ask him if he's familiar with Squadron 1.... Glad those parts laying around taking up space could help you my friend.

ghost

Well-Known Member

- Joined

- May 25, 2006

- Location

- Hartsville/Camden,SC

Demoing a storage shed on the MIL's property. I have a couple people lined up... could always use more hammers and hands.... Might even get to rent a mini excavator....How often do you get down towards Orangeburg? And what are you doing Saturday? There's a gnarly junkyard you've probably never been to calling your name.

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

Sounds like you're busy.Demoing a storage shed on the MIL's property. I have a couple people lined up... could always use more hammers and hands.... Might even get to rent a mini excavator....

ghost

Well-Known Member

- Joined

- May 25, 2006

- Location

- Hartsville/Camden,SC

Yes hopefully this is the last "project" over there besides cutting grass and things like that....Sounds like you're busy.

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

I'll let ya know how my day looks. I've got to restock on stuff from the junkyard. I'll more than likely throw the kayak on the roof with camping gear and make an Edisto river road trip out of it. Not sure who's gonna be riding with me yet.Yes hopefully this is the last "project" over there besides cutting grass and things like that....

justjeepin86

Well-Known Member

- Joined

- Jul 9, 2005

- Location

- Winston-Salem, NC

It has to be Fuggin hot in there during summer! Nothing you can't handle, of course.We've got a film crew here with us today. We are working on a bench project for the city of Cayce that much like a lot of what we do, has never quite been seen before. This guy will be filming various stages of the project. CAD drawing, loading plate material onto the table, welding and fabrication, sandblasting and powder coating, and even install. View attachment 328045View attachment 328046

View attachment 328047

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

Oh, it is. Even our intensifier pump catches hell. The KMT 60 Pro we have takes city water (80 psi?), and after three levels of filtration, pumps the pressure up to whatever I set it at up to 90ksi. I'm currently running at 52ksi.It has to be Fuggin hot in there during summer! Nothing you can't handle, of course.

This pump has been running all morning. You'll notice the temperature is at 98. That's normal for it run 20-25 degrees above outside air temperature. It's currently 73 outside.

Now, take a 100 degree day for example, same equation. Problem is, once the pump temperature gets up to around 120, it'll shut down as a thermal safety fault to prevent internal damage.

Pure hell.

It got so bad over the summer that we actually built an HVAC system to blow directly into it.

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

I've got my own parking spot.

What happens in the Waterjet building, stays between me and the CNC programmer.... And amongst any of my NC4X4 family. You're welcome.

What happens in the Waterjet building, stays between me and the CNC programmer.... And amongst any of my NC4X4 family. You're welcome.

Bam.

Bam.

Last edited:

ghost

Well-Known Member

- Joined

- May 25, 2006

- Location

- Hartsville/Camden,SC

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

That would be it.

Just say when.

- Joined

- Apr 16, 2005

- Location

- Sharon, SC

but did you win?A sufficient rear driveshaft just got moved up on my list. I knew from the start that a Spicer 1310-1330 wouldn't last long, especially with 4.56 gears and the aggressiveness of a Yukon Grizzly locker. Pair that with a peppy 5.3 litre and a bulletproof 42 year old manual transmission.... BI-YYYYOWWWWW!!!! (Crunch, grind...FML) Drag racing that squat truck had nothing to do with it.

Coast, did I to a halt in a moderately safe traffic-free spot, jumped out with a 5/16 wrench in hand, pulled the rear driveshaft bolts to the T-case yoke, threw the rear shaft in the cargo area and skeeted back home in 4-hi glory.

Yee. Yee.

View attachment 328609

View attachment 328610

View attachment 328611

Spare parts for the win. I fully intend to take the boat out with my dad to enjoy a weekend in the swamp.

The LS Jeep life ain't no BS.

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

At least up until I grabbed second.but did you win?

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

In case you've missed it, this is what I'm about. This is what I live and die for. Catch me outside.... V8s and 2 strokes for life.

...to be continued. I'll be doing this the rest of my life.

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

...continued

Go out and live. No one else is going to do it for you. ~XJsavage

Go out and live. No one else is going to do it for you. ~XJsavage

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

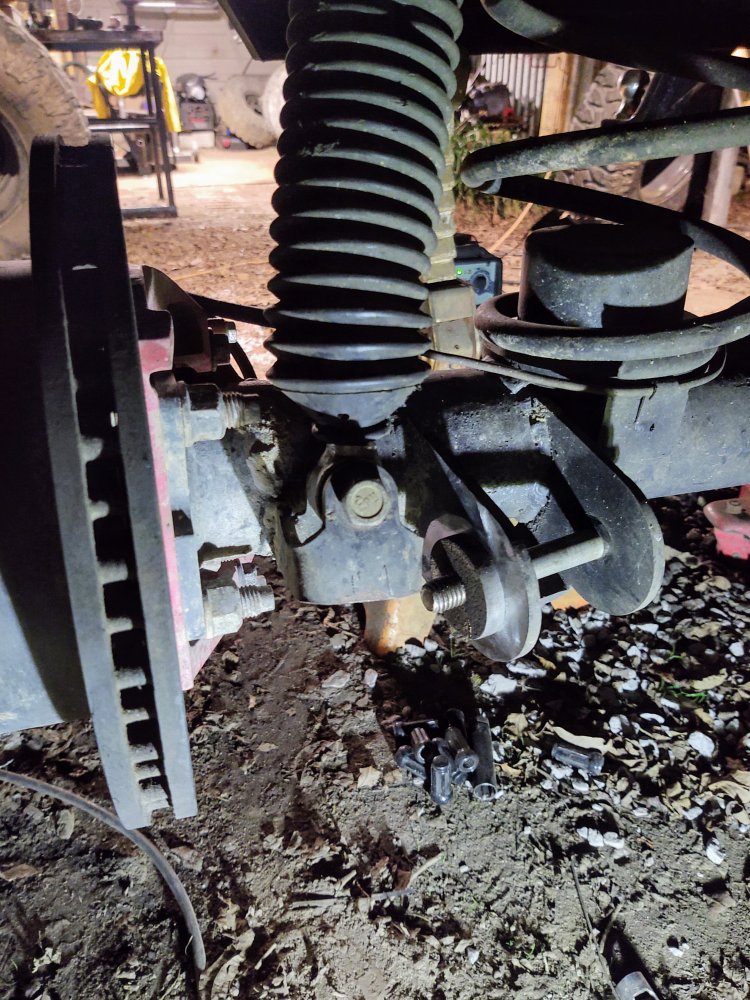

This pretty much sums up my Sunday afternoon.

A week or so ago I started noticing my rear 4-link brackets are starting to get a little sloppy finally. The lower link brackets are presumably A36 laser cut .25", while the upper brackets are .188 A500 (at least at the frame end). The A500 upper brackets have held up better than the lowers have. A500 Grade A has a yield strength of ~45-50KSI, while A36 has a yield strength of ~36KSI.

*Nerdy stuff I'll get back to later*

Saturday road trip: Hitting one of my favoritest junkyards for some driveshaft parts. I like stuff that I can't break. When I grenaded my rear driveshaft a week ago, I had to borrow some parts off my front shaft to get back on the road and most importantly, to work the next day. When I built this Jeep I knew the driveshafts wouldn't last long. It was one of those "throw a bunch of bullshit together and get it drivable" scenarios. Temporary, in other words. It required some ghettodaptation of everything from 1310-1350 and everything in between. The 1310 CV is insufficient. I've had to rebuild it twice already. The 1330 is a joke. A 1350 is borderline.

I stumbled upon a little gem while I was strolling around the junkyard. It just so happens to be the perfect length for the front, and with 1410 joints to boot. I'll have to order new yokes obviously, but this should do the trick.

The junkyard I went to was in the lovely town of Orangeburg SC. It's about an hour drive for me to get there. Across the Congaree and through a shit ton of cotton and soy fields, but hell, every mile behind the wheel of a Jeep is what heaven is made of.

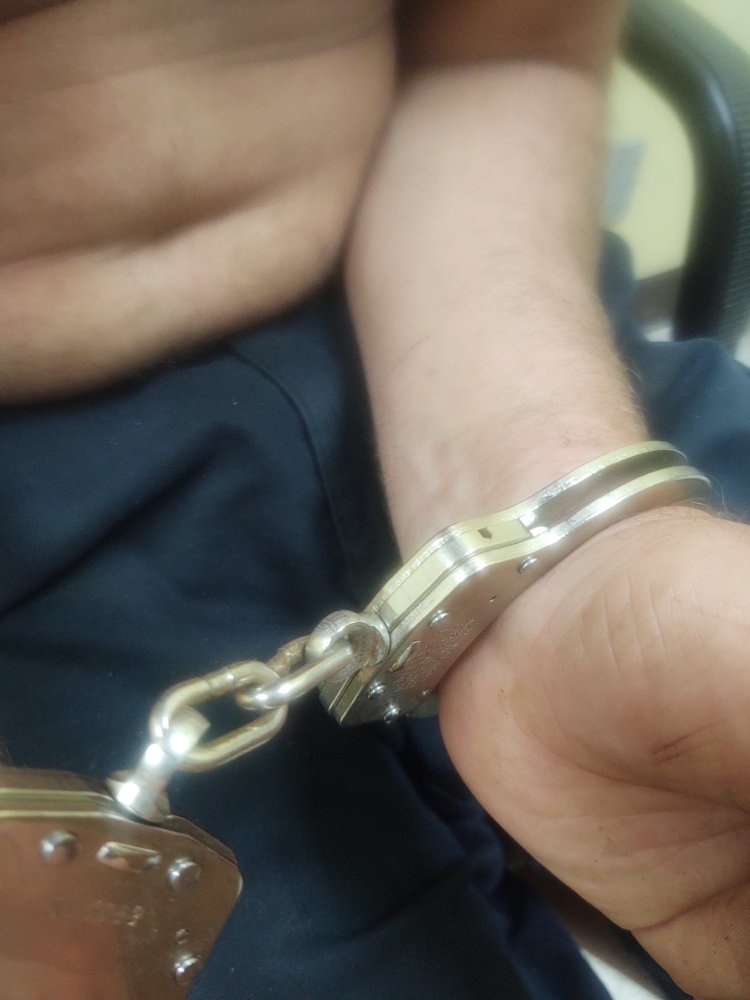

Last time I was in Orangeburg went a little something like this. If you're wondering if it's acceptable to play on your cellphone while in booking, well... It's kinda not. Slightly frowned upon actually. Write that down.

^^ old pic from a few months ago, for those speed readers out there.

Back to the nerdy stuff.

As a remedy for the hole slop I've been getting on my rear link brackets, I decided that some custom weld washers would be the ticket. All of my link bolts (upper and lower) are 5/8". I could've easily just ordered a full set of weld washers from one of our many online off-road parts suppliers, but with the excessive amount of scrap material just laying around the shop where I work, I figured, well I'll just make my own. We were recently working with a few sheets of A656 1018 3/8" steel. The yield strength of this particular alloy is upwards of 80-90KSI which is ridiculously strong compared to most typical mild steel. I thought it would be a perfect candidate for what I was going to use it for. There were 16 pieces cut total. 2" round washers, 8 with a 5/8" thru hole, and the other 8 with a 7/16" (which I later went through and enlarged to 17/32 and tapped to 5/8-11).

Tapping these to 5/8" was not easy to do. This is some very hard steel.

A week or so ago I started noticing my rear 4-link brackets are starting to get a little sloppy finally. The lower link brackets are presumably A36 laser cut .25", while the upper brackets are .188 A500 (at least at the frame end). The A500 upper brackets have held up better than the lowers have. A500 Grade A has a yield strength of ~45-50KSI, while A36 has a yield strength of ~36KSI.

*Nerdy stuff I'll get back to later*

Saturday road trip: Hitting one of my favoritest junkyards for some driveshaft parts. I like stuff that I can't break. When I grenaded my rear driveshaft a week ago, I had to borrow some parts off my front shaft to get back on the road and most importantly, to work the next day. When I built this Jeep I knew the driveshafts wouldn't last long. It was one of those "throw a bunch of bullshit together and get it drivable" scenarios. Temporary, in other words. It required some ghettodaptation of everything from 1310-1350 and everything in between. The 1310 CV is insufficient. I've had to rebuild it twice already. The 1330 is a joke. A 1350 is borderline.

I stumbled upon a little gem while I was strolling around the junkyard. It just so happens to be the perfect length for the front, and with 1410 joints to boot. I'll have to order new yokes obviously, but this should do the trick.

The junkyard I went to was in the lovely town of Orangeburg SC. It's about an hour drive for me to get there. Across the Congaree and through a shit ton of cotton and soy fields, but hell, every mile behind the wheel of a Jeep is what heaven is made of.

Last time I was in Orangeburg went a little something like this. If you're wondering if it's acceptable to play on your cellphone while in booking, well... It's kinda not. Slightly frowned upon actually. Write that down.

^^ old pic from a few months ago, for those speed readers out there.

Back to the nerdy stuff.

As a remedy for the hole slop I've been getting on my rear link brackets, I decided that some custom weld washers would be the ticket. All of my link bolts (upper and lower) are 5/8". I could've easily just ordered a full set of weld washers from one of our many online off-road parts suppliers, but with the excessive amount of scrap material just laying around the shop where I work, I figured, well I'll just make my own. We were recently working with a few sheets of A656 1018 3/8" steel. The yield strength of this particular alloy is upwards of 80-90KSI which is ridiculously strong compared to most typical mild steel. I thought it would be a perfect candidate for what I was going to use it for. There were 16 pieces cut total. 2" round washers, 8 with a 5/8" thru hole, and the other 8 with a 7/16" (which I later went through and enlarged to 17/32 and tapped to 5/8-11).

Tapping these to 5/8" was not easy to do. This is some very hard steel.

This pretty much sums up my Sunday afternoon.

View attachment 329204

A week or so ago I started noticing my rear 4-link brackets are starting to get a little sloppy finally. The lower link brackets are presumably A36 laser cut .25", while the upper brackets are .188 A500 (at least at the frame end). The A500 upper brackets have held up better than the lowers have. A500 Grade A has a yield strength of ~45-50KSI, while A36 has a yield strength of ~36KSI.

*Nerdy stuff I'll get back to later*

Saturday road trip: Hitting one of my favoritest junkyards for some driveshaft parts. I like stuff that I can't break. When I grenaded my rear driveshaft a week ago, I had to borrow some parts off my front shaft to get back on the road and most importantly, to work the next day. When I built this Jeep I knew the driveshafts wouldn't last long. It was one of those "throw a bunch of bullshit together and get it drivable" scenarios. Temporary, in other words. It required some ghettodaptation of everything from 1310-1350 and everything in between. The 1310 CV is insufficient. I've had to rebuild it twice already. The 1330 is a joke. A 1350 is borderline.

I stumbled upon a little gem while I was strolling around the junkyard. It just so happens to be the perfect length for the front, and with 1410 joints to boot. I'll have to order new yokes obviously, but this should do the trick.

View attachment 329205

The junkyard I went to was in the lovely town of Orangeburg SC. It's about an hour drive for me to get there. Across the Congaree and through a shit ton of cotton and soy fields, but hell, every mile behind the wheel of a Jeep is what heaven is made of.

Last time I was in Orangeburg went a little something like this. If you're wondering if it's acceptable to play on your cellphone while in booking, well... It's kinda not. Slightly frowned upon actually. Write that down. View attachment 329206

^^ old pic from a few months ago, for those speed readers out there.

Back to the nerdy stuff.

As a remedy for the hole slop I've been getting on my rear link brackets, I decided that some custom weld washers would be the ticket. All of my link bolts (upper and lower) are 5/8". I could've easily just ordered a full set of weld washers from one of our many online off-road parts suppliers, but with the excessive amount of scrap material just laying around the shop where I work, I figured, well I'll just make my own. We were recently working with a few sheets of A656 1018 3/8" steel. The yield strength of this particular alloy is upwards of 80-90KSI which is ridiculously strong compared to most typical mild steel. I thought it would be a perfect candidate for what I was going to use it for. There were 16 pieces cut total. 2" round washers, 8 with a 5/8" thru hole, and the other 8 with a 7/16" (which I later went through and enlarged to 17/32 and tapped to 5/8-11).

View attachment 329207

Tapping these to 5/8" was not easy to do. This is some very hard steel.

View attachment 329208

Worth it. It’s all worth it. YOLO

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

I hope so.Worth it. It’s all worth it. YOLO

2020 has been a living hell for a lot of people and I pray to God that the good times return. I don't know why, but that thought has been popping up in my head a lot lately. Just in the last few months, not even in the entirety of 2020 for me personally I attended the funeral of one of my closest friends, have another one that I may never see again, I've broken bones, been put behind bars in two states, even had the worst depression breakdown I hoped I would never see. Coronavirus? Who's she? A ruthless demonic bitch.

RIP my brother Andrew "307" Bunnell.

True, it does suck being told what to do, but it's far worse to be told what you can't.

XJsavage

CounterCulture

- Joined

- Aug 15, 2009

- Location

- Lyle's Ford SC

Weld washer install. I have to really plan and stage certain tasks moreso than ever since this is currently my only means of transportation besides on foot. It keeps thing fun.

I just call it a backyard welding party that nobody shows up to unless there's food and free beer....and then they still don't.

My objective for the night was to get the weld washers on my lower links completed. Once I did, it's put the Jeep back together to drive to work in the am. Tomorrow night will be same procedure, just with the uppers. My Esab 161LTS is holding in there like a boss. Still a surprisingly durable and smooth running machine on stick. I've YET to even try the TIG function. I will be needing it once I start my new SS fuel cell.

Sooner or later I'll start replacing the current parts for all new 1.25 Heims and Al links. Next year at the earliest.

The Hobart 7018s are OK for cheap rods.

Working on the uppers is gonna bring the suck.

I just call it a backyard welding party that nobody shows up to unless there's food and free beer....and then they still don't.

My objective for the night was to get the weld washers on my lower links completed. Once I did, it's put the Jeep back together to drive to work in the am. Tomorrow night will be same procedure, just with the uppers. My Esab 161LTS is holding in there like a boss. Still a surprisingly durable and smooth running machine on stick. I've YET to even try the TIG function. I will be needing it once I start my new SS fuel cell.

Sooner or later I'll start replacing the current parts for all new 1.25 Heims and Al links. Next year at the earliest.

The Hobart 7018s are OK for cheap rods.

Working on the uppers is gonna bring the suck.