You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Random Metal Fab Fun.

- Thread starter WARRIORWELDING

- Start date

WARRIORWELDING

Owner opperator Of WarriorWelding LLC.

- Joined

- Jan 6, 2008

- Location

- Chillin, Hwy 64 Mocksville NC

I like the use of the bed instead of a drop in full box, lots more space.

hurt4x4

Well-Known Member

- Joined

- Sep 12, 2012

- Location

- Greensboro

This thread needs a bump.

Necklace hanger I've been working on for my GF

The base, twist and rolls at the top all done by hand.

Necklace hanger I've been working on for my GF

The base, twist and rolls at the top all done by hand.

MarsFab

Will work for money

- Joined

- Oct 24, 2007

- Location

- Harrisburg, NC

That's pretty dang cool!

WARRIORWELDING

Owner opperator Of WarriorWelding LLC.

- Joined

- Jan 6, 2008

- Location

- Chillin, Hwy 64 Mocksville NC

Tom@Hilltop_Machine

Well-Known Member

- Joined

- Mar 31, 2005

- Location

- Rural Retreat, VA

X2Nice fab table @hurt4x4

ponykilr

Guest

I have heated with wood for several years with my second hand Squire woodstove. We heated with wood when I was a kid and it just feels "right" to me. I love the stove, b ut I wanted to make a few changes to make it look a little more modern. It was the classic Squire with 2 cast doors, 70's chic.

Out on the back porch on my dolly

I started with a plan to add secondary air tubes to make it more efficient. I used steel threaded pipe and pulled the air from the inside of the double wall.

Once I had that done, I started on a new door with ceramic glass so we could see the flames. I used 3/8 plate for the door. I added the sill for the glass to sit in and used fiberglass fireplace gasket to seal it. It bolts in so if I ever need to replace the glass or gasket it will be easy. I made the latch with a long 5/8 bolt that pivots in a nut welded to the door. Air tight and nothing to wear out. I had to cut the hinge off of the left side and had to fab up hinges to line up with the hinge on the right. I used my draft knobs from the old doors and I think it looks great. The stove works wonderful and with the new pewter paint job it has a steam punk feel. We are very happy with it and it was a fun project.

Clamped in position to make the hinges.

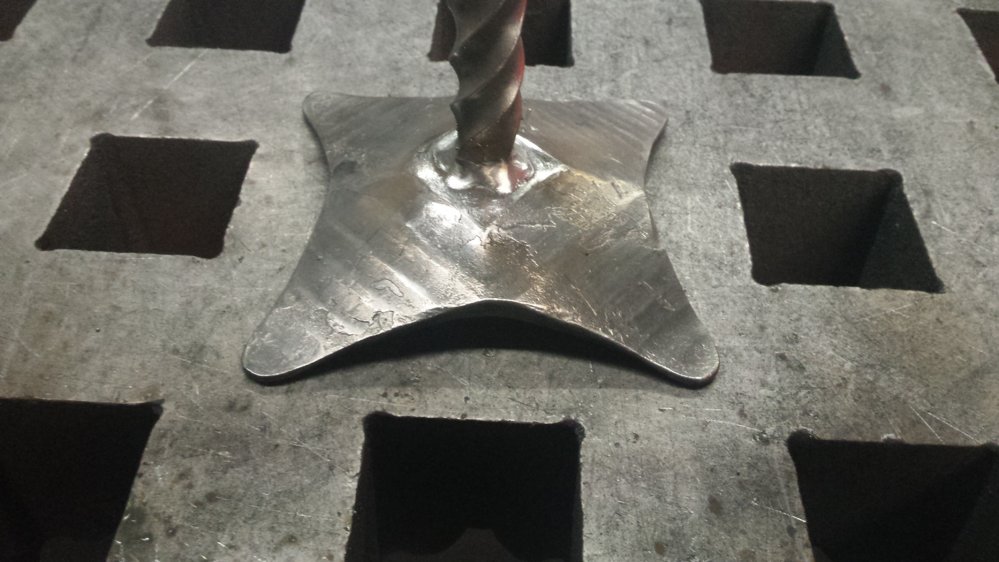

Drilling for the hinge pin.

Ready to weld.

Welded up.

Latch pivot.

Draft holes and controls

For some reason, I did not take pics of the sill for the glass. It is 1-1/2 x 1/8 flat bar welded around the inside perimeter of the hole. The front is 1 x 1/8 flat bar and it bolts over the glass and gasket. This leaves 3/8" (thickness of the door) for the 3/16 ceramic glass and 1/8 x 1 fiberglass gasket that wraps around the glass.

I love the look and it looks like a modern stove instead of a throwback to the Carter administration.

Out on the back porch on my dolly

I started with a plan to add secondary air tubes to make it more efficient. I used steel threaded pipe and pulled the air from the inside of the double wall.

Once I had that done, I started on a new door with ceramic glass so we could see the flames. I used 3/8 plate for the door. I added the sill for the glass to sit in and used fiberglass fireplace gasket to seal it. It bolts in so if I ever need to replace the glass or gasket it will be easy. I made the latch with a long 5/8 bolt that pivots in a nut welded to the door. Air tight and nothing to wear out. I had to cut the hinge off of the left side and had to fab up hinges to line up with the hinge on the right. I used my draft knobs from the old doors and I think it looks great. The stove works wonderful and with the new pewter paint job it has a steam punk feel. We are very happy with it and it was a fun project.

Clamped in position to make the hinges.

Drilling for the hinge pin.

Ready to weld.

Welded up.

Latch pivot.

Draft holes and controls

For some reason, I did not take pics of the sill for the glass. It is 1-1/2 x 1/8 flat bar welded around the inside perimeter of the hole. The front is 1 x 1/8 flat bar and it bolts over the glass and gasket. This leaves 3/8" (thickness of the door) for the 3/16 ceramic glass and 1/8 x 1 fiberglass gasket that wraps around the glass.

I love the look and it looks like a modern stove instead of a throwback to the Carter administration.

Last edited by a moderator:

frankenyoter

No Rain, No Rainbow

- Joined

- Mar 17, 2009

- Location

- DARK CITY

Nice job ponykilr!

WARRIORWELDING

Owner opperator Of WarriorWelding LLC.

- Joined

- Jan 6, 2008

- Location

- Chillin, Hwy 64 Mocksville NC

Recycled washing machine drums. Rainy day project with my son.

livetorun

Mammary Enthusiast

- Joined

- Jul 20, 2008

- Location

- Louisburg, NC

Fantasy football trophy I made this weekend.

ponykilr

Guest

Hard to believe that this thread is from last year! My wood stove is still performing great and looks like something I bought.

When I pulled it this summer to brush out the chimney, I improved the airwash for the glass door to keep it cleaner.

Still untested, but I think it will work better.

I built a nice woodshed this past summer that can hold over 4 cords.

I am working on a sleeve hitch setup for my John Deere 265 lawn tractor. It will use an electric screw drive actuator instead of hydraulic.

These actuators are rated at up to 1000lbs force and will be much simpler to fab up compared to hydraulics.

Sleeve hitches allow a simple way to use implements. My neighbor has a small lawn tractor with one and a blade, rake, bucket, plow......

Real work savers that I have seen in action, one of those things you don't want to be without once you use them.

Not my video, but a similar setup.

When I pulled it this summer to brush out the chimney, I improved the airwash for the glass door to keep it cleaner.

Still untested, but I think it will work better.

I built a nice woodshed this past summer that can hold over 4 cords.

I am working on a sleeve hitch setup for my John Deere 265 lawn tractor. It will use an electric screw drive actuator instead of hydraulic.

These actuators are rated at up to 1000lbs force and will be much simpler to fab up compared to hydraulics.

Sleeve hitches allow a simple way to use implements. My neighbor has a small lawn tractor with one and a blade, rake, bucket, plow......

Real work savers that I have seen in action, one of those things you don't want to be without once you use them.

Not my video, but a similar setup.

Chuckman

Well-Known Member

- Joined

- Oct 9, 2005

- Location

- Huntersville

^ how does that work with the up and down force of plowing. hydraulics naturally can handle the dampening, but will that screw drive last? Its way cool though!!

ponykilr

Guest

Lots of people use them. In fact Cub Cadet had models with screw drive sleeve hitches from the factory. The are rated for dynamic (moving) load and static. 1000lbs is way more rating than needed for anything the tractor can do.

WARRIORWELDING

Owner opperator Of WarriorWelding LLC.

- Joined

- Jan 6, 2008

- Location

- Chillin, Hwy 64 Mocksville NC

All thin gauge sheet metal. Used GTAW, SMAW to get effects I wanted. The log was 6 inches od and the handle started as 3/4 thin wall tube. The stubby branches started as header tubing drops.

hurt4x4

Well-Known Member

- Joined

- Sep 12, 2012

- Location

- Greensboro

Awesome. How many hours do you have into that?

frankenyoter

No Rain, No Rainbow

- Joined

- Mar 17, 2009

- Location

- DARK CITY

View attachment 201606

All thin gauge sheet metal. Used GTAW, SMAW to get effects I wanted. The log was 6 inches od and the handle started as 3/4 thin wall tube. The stubby branches started as header tubing drops.

View attachment 201607

One of the coolest things ever....PERIOD!

- Joined

- Mar 24, 2005

- Location

- Stanley, NC

Dammit. I made the mistake of showing this to my wife. Thanks a lot.View attachment 201606

All thin gauge sheet metal. Used GTAW, SMAW to get effects I wanted. The log was 6 inches od and the handle started as 3/4 thin wall tube. The stubby branches started as header tubing drops.

View attachment 201607

WARRIORWELDING

Owner opperator Of WarriorWelding LLC.

- Joined

- Jan 6, 2008

- Location

- Chillin, Hwy 64 Mocksville NC

Around 16. Thanks guys. It is for a customer. They are also great friends. It is a Christmas present for their father. The families last name is Hatchett.Awesome. How many hours do you have into that?

StokesCo.94HB

Well-Known Member

- Joined

- Aug 24, 2005

- Location

- Rural Hall, NC

That f'n thing is freaking awesome. One of the coolest pieces of metal work I've seen.

YotaOnRocks

Well-Known Member

- Joined

- Jul 17, 2007

- Location

- Madison

Been a while since I did any copper work this was from a couple years ago all made from 3x10 sheets

Before

After

Before

After

Dirt Mcgert

Well-Known Member

- Joined

- Jan 31, 2008

- Location

- lexington sc

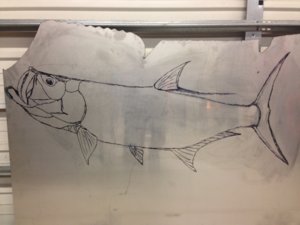

Here are a few things I've made out of scrap stainless in the past year or two

Attachments

Dirt Mcgert

Well-Known Member

- Joined

- Jan 31, 2008

- Location

- lexington sc

Dirt Mcgert

Well-Known Member

- Joined

- Jan 31, 2008

- Location

- lexington sc

WARRIORWELDING

Owner opperator Of WarriorWelding LLC.

- Joined

- Jan 6, 2008

- Location

- Chillin, Hwy 64 Mocksville NC

The fish are awsome. Do you vary welding tip sizes or use a standard cutting head or rosebud? Looks like you have mastered control ing the heat. P an O sheets or any of it SS?

Dirt Mcgert

Well-Known Member

- Joined

- Jan 31, 2008

- Location

- lexington sc

I have a rose bud tip , but I rarely use it , pretty much do it all with a welding tip and vary the pressures , its all stainless , different grades and thicknesses