If your pedal is firm, but the brakes arent locking up, I would bet that lines/hoses arent your issue. It is likely that you arent able to extert enough force to lockup the brakes (ie you cant generate enough pressure).

What calipers and rotors are you running again? What is the bore on your master? What was the bore on your old master?

Then maybe its not "firm". Its not as "firm" as the corolla or our other vehicles (newer).

I am using 3/4 chevy rotors and calipers. I had a stock CJ master on there and "emergency braking" wasnt a possiblility, neither was lockup. Now with the e350 my braking distance is definitley smaller. I would feel better in emergency situation but i still can not lock up.

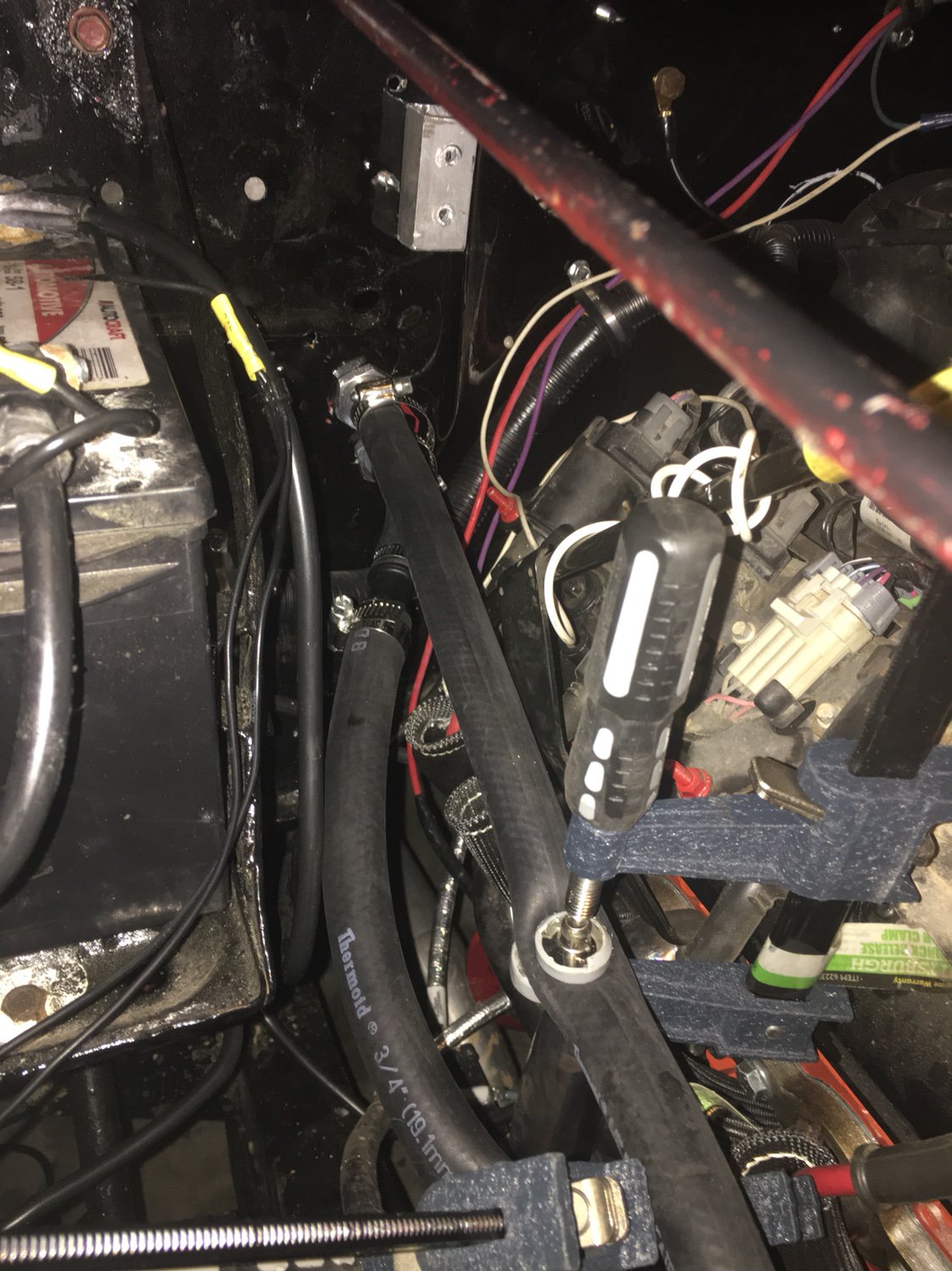

When the engine is off the firmness of the pedal feels like a stock newer vehicle, but slightly harder. with the engine on (booster), my initial reaction everytime i use the brakes is "man, this travels Too easy...".

At first I looked into the travel distance of the pedal. I thought maybe it just wasnt enough? So i lengthened it about 3/8 to 7/16 an inch - no change. however i did do that when i had an unknown piston rod length issue. regardless moving it that much put the pedal so high you have to lift your foot to use it, rather than pivoting your foot on your heel. took a dangerous moment or two to get used to that, but one stupid asheville driver almost had their rearend caved in because doing it that way (lift the foot all the way, like for clutch pedal) resulted in my foot getting caught under the pedal. barely stopped in time for that one. lol.

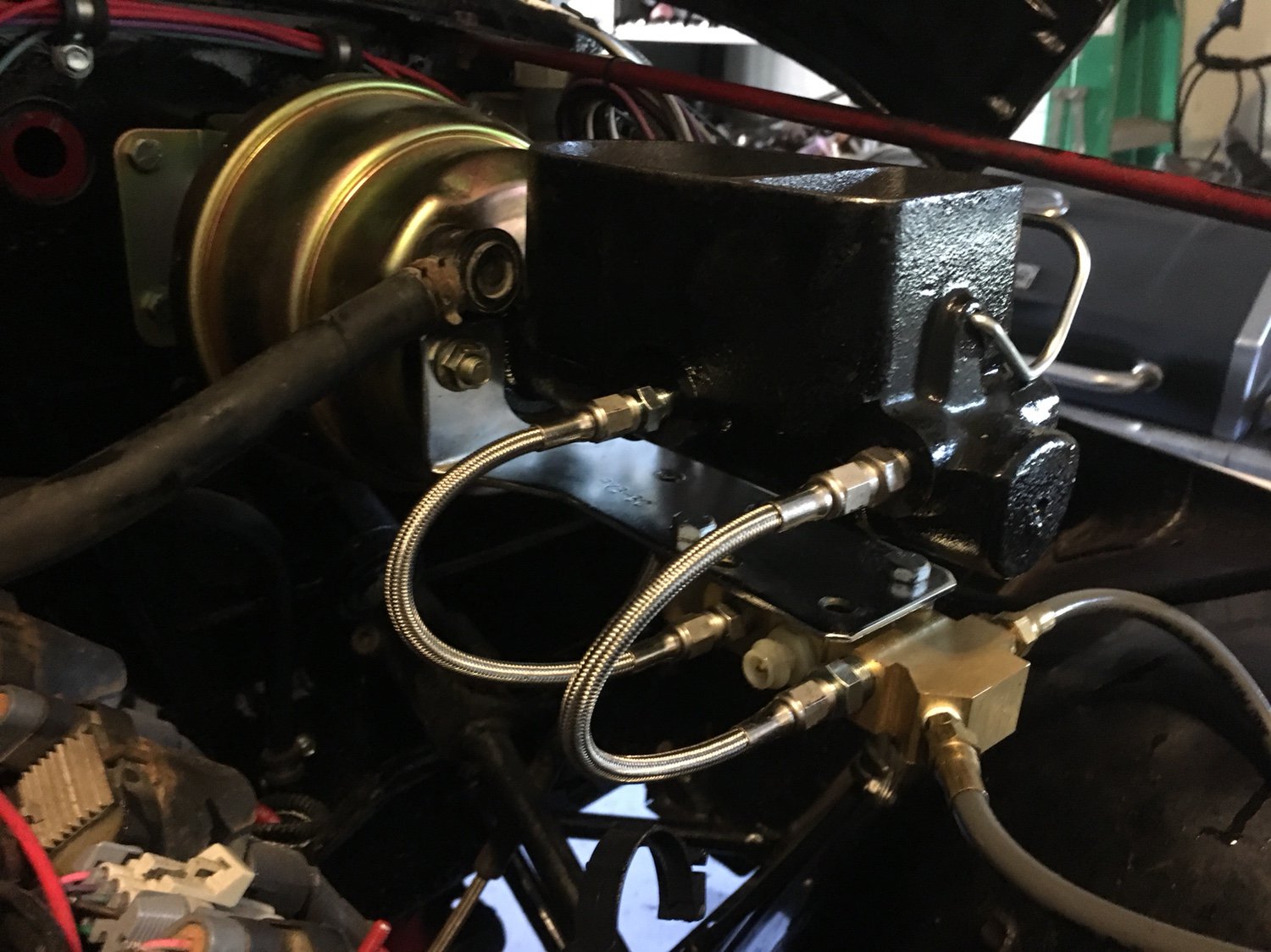

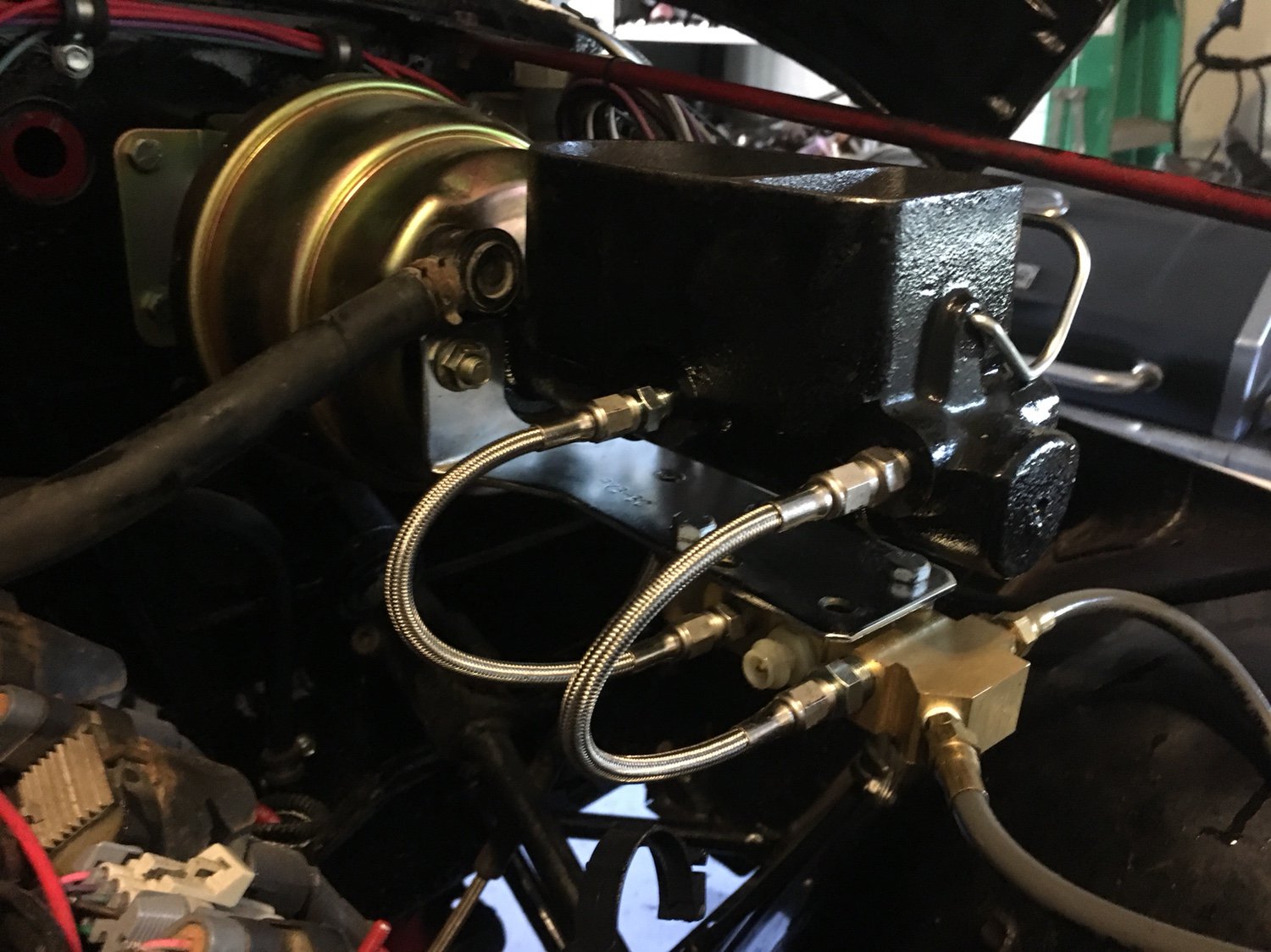

Anywho, hoping to leave the pedal where its at for safety reasons. I can now confirm that the piston rod from the booster is about 1/8 inch from the seat of the piston. For max throw. My brakes and master have been bled (to the best of my ability without a vacuum bleeder). Seeing as how everyone and their mother does these 3/4 ton master and caliper swaps, i have a hard time believing they could be the issue? but im certainly not the expert.

My gut says its either these lines (non braided so they should have some amount of expanding flex?), or its the booster. I dont know enough about booster technology. The way I understand it, its just a vac diaphram to help give more force on the brake pedal to rod to m/c piston. However if that rod isnt going all the way through, but relies on one diaphragm with pedal and rod to push on another diaphragm with rod to piston, then perhaps there is something defective that is not allowing the rod to piston to travel the same distance as the rod from the pedal, resulting in proper throw with engine off, but defective throw with engine on. But that cant be it i think because to my knowledge the rod goes all the way through? and if that was true then when i had the big issue with the improper piston end rod length i would have wrecked many times over?

The only thing i know to do is lines (which everyone says to do anyways for longevity and safety reasons).

@XJsavage had the simple idea for the old school tabs, but also curious about these barnes tabs that

@YJJPWrangler pointed out.

Thanks

@paradisePWoffrd for the help! Any thoughts after this diahrea of the keyboard? lol.