Croatan_Kid

How's your hammer hangin'?

- Joined

- Nov 4, 2007

- Location

- New Bern

I really wish I knew the guy that welded this dumbass gooseneck hitch on this truck so I could kick him square in the vagina. This crap is starting to be a lot of work! Whoever it was literally went through more trouble than it was worth and put more effort in to making and installing that dumpster fire of a hitch than if they had just spent a few bucks on a good hitch. At the very least they could have used something that wouldn't make your insurance company drop you if there was a wreck.

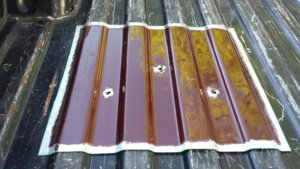

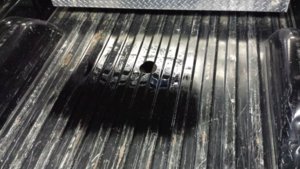

I got everything cut off/ ground down and cut out the heat shield under the bed to make room for the new hitch. Now I just have to fit the patch piece in the bed floor, weld it in, and shoot some paint. Then the new hitch can go together. I'm getting to the short rows now, finally!

I got everything cut off/ ground down and cut out the heat shield under the bed to make room for the new hitch. Now I just have to fit the patch piece in the bed floor, weld it in, and shoot some paint. Then the new hitch can go together. I'm getting to the short rows now, finally!