marty79

the LS Swap Guy

- Joined

- Nov 24, 2013

- Location

- Conover, NC

Other end has this and its hooked up already to main CNC box thingy.

Sweet thank you@marty79 if you’re an inside track member these are on sale

Scratch that, just need the coupon

4 ft. x 6 ft. Fiberglass Welding Blanket

Amazing deals on this 4Ft X 6Ft Fiberglass Welding Blanket at Harbor Freight. Quality tools & low prices.www.harborfreight.com

And not a fuzzy magnet for all sorts of stuff! I hate a fire blanket unless I use it for its purpose on something. I will go out of my way to protect stuff with sheet goods or even leather I have stashed. The blanket is only when nothing else fits.Why not just use sheetrock? Cheap and quick.

That sounds good, thanks for heads upWhy not just use sheetrock? Cheap and quick.

Whateryou an expert on welding or sumthin?And not a fuzzy magnet for all sorts of stuff! I hate a fire blanket unless I use it for its purpose on something. I will go out of my way to protect stuff with sheet goods or even leather I have stashed. The blanket is only when nothing else fits.

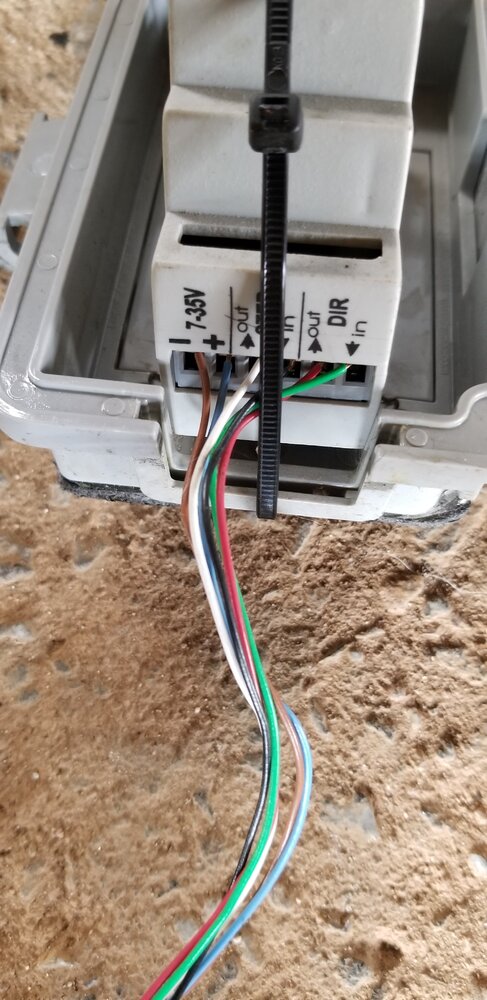

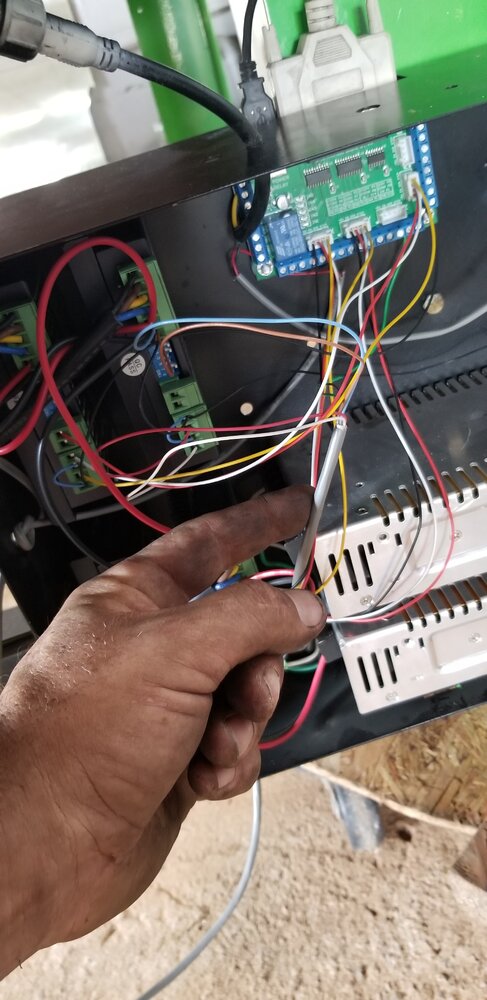

ok so this side of the THC is obviously going to the CNC black box controller...the guy I bought it from left some of the wiring plugged in but disconnected others. I wish the THC was left connected lol, the other big wires going to CNC box and the mechanized rollers are self explanatory mostly haha, leaves me with the headache.You should have two wires from the plasma going to that torch height controller that are showing it arc voltage so it can sense and change torch height based on arc voltage and two wires from the cnc control going to the plasma that are from a discrete output that tell it to turn the arc on or off. Then you have wires going from the thc to the cnc control telling it whether to raise or lower the Z axis in order to control arc voltage.

ok so this side of the THC is obviously going to the CNC black box controller...the guy I bought it from left some of the wiring plugged in but disconnected others. I wish the THC was left connected lol, the other big wires going to CNC box and the mechanized rollers are self explanatory mostly haha, leaves me with the headache.You should have two wires from the plasma going to that torch height controller that are showing it arc voltage so it can sense and change torch height based on arc voltage and two wires from the cnc control going to the plasma that are from a discrete output that tell it to turn the arc on or off. Then you have wires going from the thc to the cnc control telling it whether to raise or lower the Z axis in order to control arc voltage.

Not really, I haven't stopped learnin'.Whateryou an expert on welding or sumthin?

Ground rod independent of everything just for the table if you haven't already.Mach 3 is pretty simple to run, biggest issues I ever had running the plasma where I used to work was noise. Make sure your signal/trigger wires are no where close to the plasma torch lead. Will cause some really weird issues. Also if the plasma has a poor ground (likely only talking hypertherm but) it usually initiate the arc then loose it almost instantly.

Just got a 40" rod in the ground now.Ground rod independent of everything just for the table if you haven't already.

Drill and place it next to the table....all, copper and deep!

) yet

) yetI have a plasma cam system that doesn't use all of what you stated. It uses a proprietary means of drawing conversion and machine function. Be happy to sell it. As for those you mentioned they are fairly industry standard. Many tables run the same group of software.anyone know a good "All In One" CNC software that isn't outrageous but would due the job for this line of work?

My system came with Viacad (Draw), Sheetcam (setup process/tools/G-Code), Mach3 (actually Cut program). Despite I'm figuring it out little by little, it's retarted to need to go through 3 programs to cut something when I know there's software that does drawing and cutting all in the same program..(no Gcodes and stuff) cause the program does it for you.

When I worked for ........ his system was all in one and was SOO much easier than this crap I'm working with, within few days (only an hour or so each day) i was able to draw and cut parts pretty quickly just learning the basics. You didn't have to "load" Tools and parameters (like Sheetcam makes you) and just overall was a much less stressful learning curve.

It's mind boggling how many steps you have to go through from Viacad to Sheetcam to Mach3 before you can hit the "cut" button...daiiuuum, brain overload lately not to mention still troubleshooting my system 4 days later, dam I've learned more about this software and settings than I care to LOL (but still not working) yet

Edit. Now you are truly seeing why many folks without a few of those layers in fluency don't find the pot of gold at the end of the plasma arc!

For many who get frustrated or do not digest the details it becomes a dust collector at a heavy cost.

Yes I agree it is a lot but I knew this would require stupid amount of time invested, by no means did I nor do I expect it to bring in all kinds of money right away. This was a "long term" investment for me cause without major lower spine surgery, I ain't gonna be able to do what I do for probably another 5yrs ish so this business plan was for that reason to get out of rolling around on the ground and hard manual labor and do something within this passion I love that will be easier on me and by then just have employees doing the hard labor! There's some days I don't even know how I make it (other than just shut up and work) cause my lower back gets pretty bad but it is what it is, keep on keeping on!Now you are truly seeing why many folks without a few of those layers in fluency don't find the pot of gold at the end of the plasma arc!

For many who get frustrated or do not digest the details it becomes a dust collector at a heavy cost

To be clear. Plasmacam will ONLY RUN Plasmacam products. The table and the software are a one product union. One will not operate without the other and neither speak to other tables or software. They are one of the earliest consumer models of tables. The idea was to make them completely proprietary. You either hate them or love them.wow that posted all weird, sorry this computer has issues too, mouse apparently clicks twice a lot (creating double posts) and pasting dosn't work that well. my bad

oh ok, that makes sense.To be clear. Plasmacam will ONLY RUN Plasmacam products. The table and the software are a one product union. One will not operate without the other and neither speak to other tables or software. They are one of the earliest consumer models of tables. The idea was to make them completely proprietary. You either hate them or love them.

Another layer they added is limited but costly upgrades, obsolete packages, and better equipment offered down the road purposely built to not mesh with earlier designs.

They are not horrible by any means but your married to which ever series you purchase.