ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

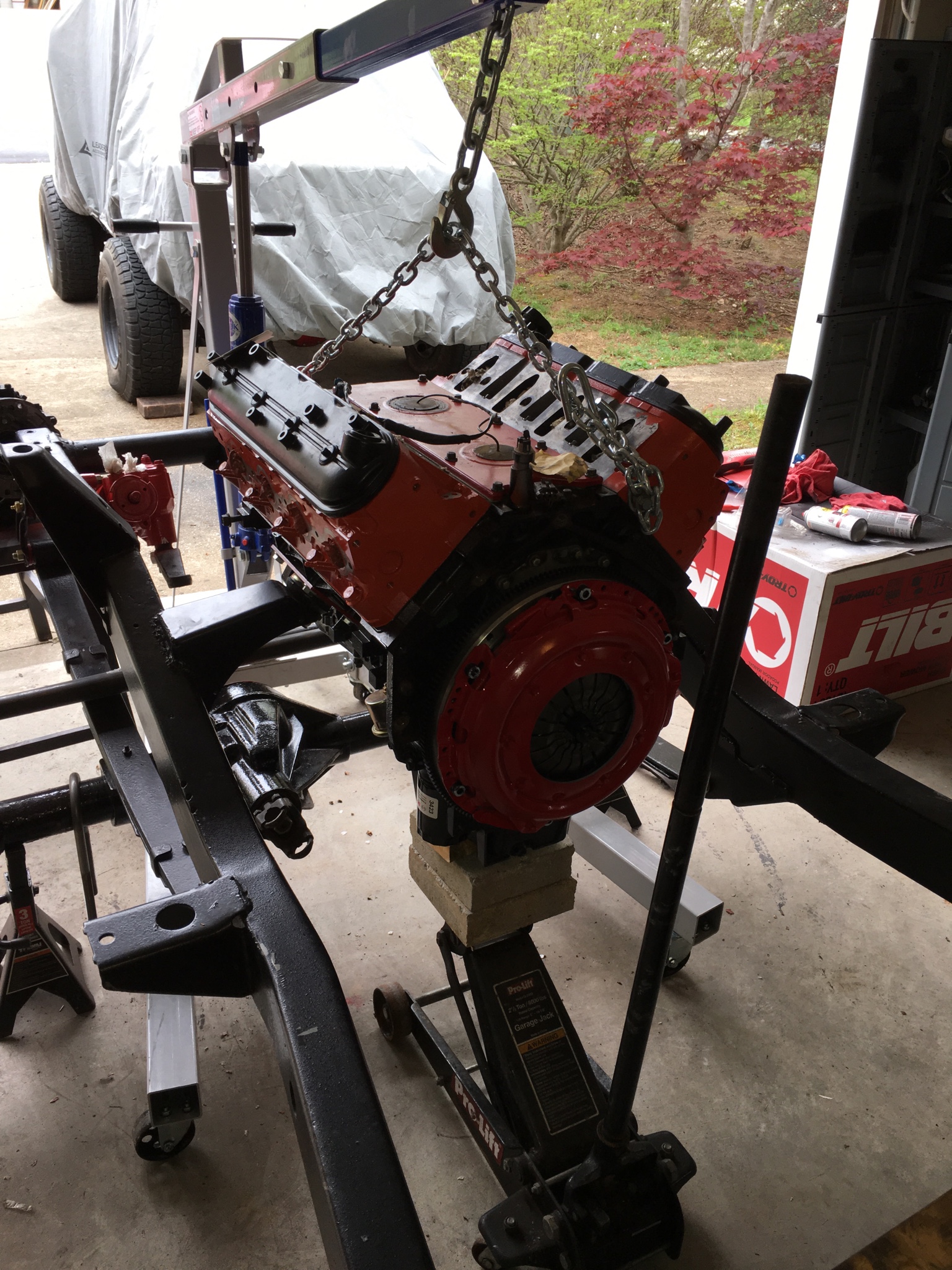

This rig better have a tub mounted on it by page 17.

Hahahah. I agree

This rig better have a tub mounted on it by page 17.

@ckruzer - back in 2014 (I think) there was a recall on some of those Kidde extinguishers, including the ones in that box. Check the Kidde website for how to tell if yours are affected. Not saying yours are affected, but it's better to confirm one way or the other before you need them.

This rig better have a tub mounted on it by page 17.

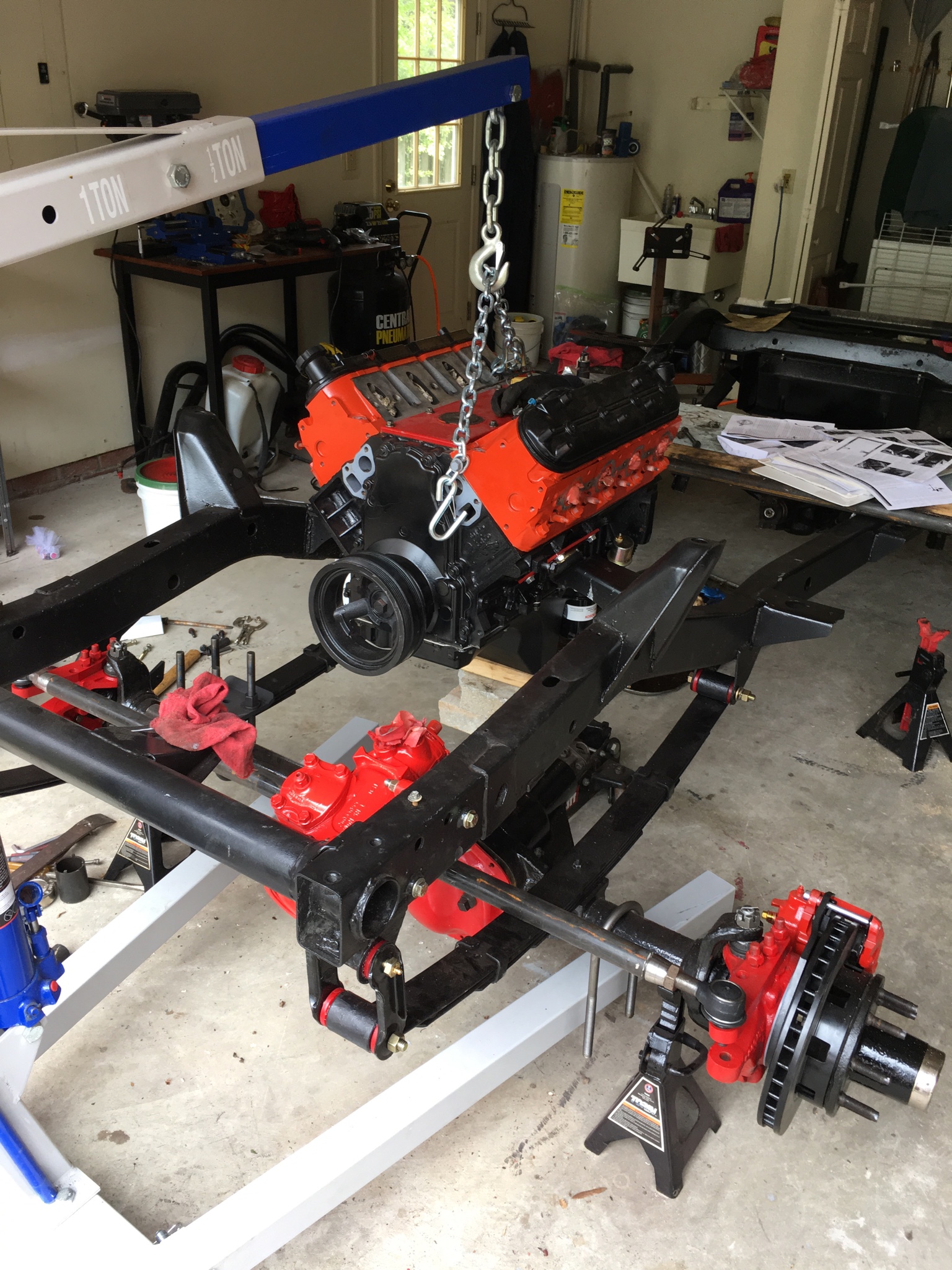

That's like 10 degrees from nowGot a deadline of June 1st to drive 60mph

got the shout out and everything!

Not falling for that crap.busy busy busy weekend. new sending unit ordered tho

Not falling for that crap.

Temp? Oil pressure? Fuel level?

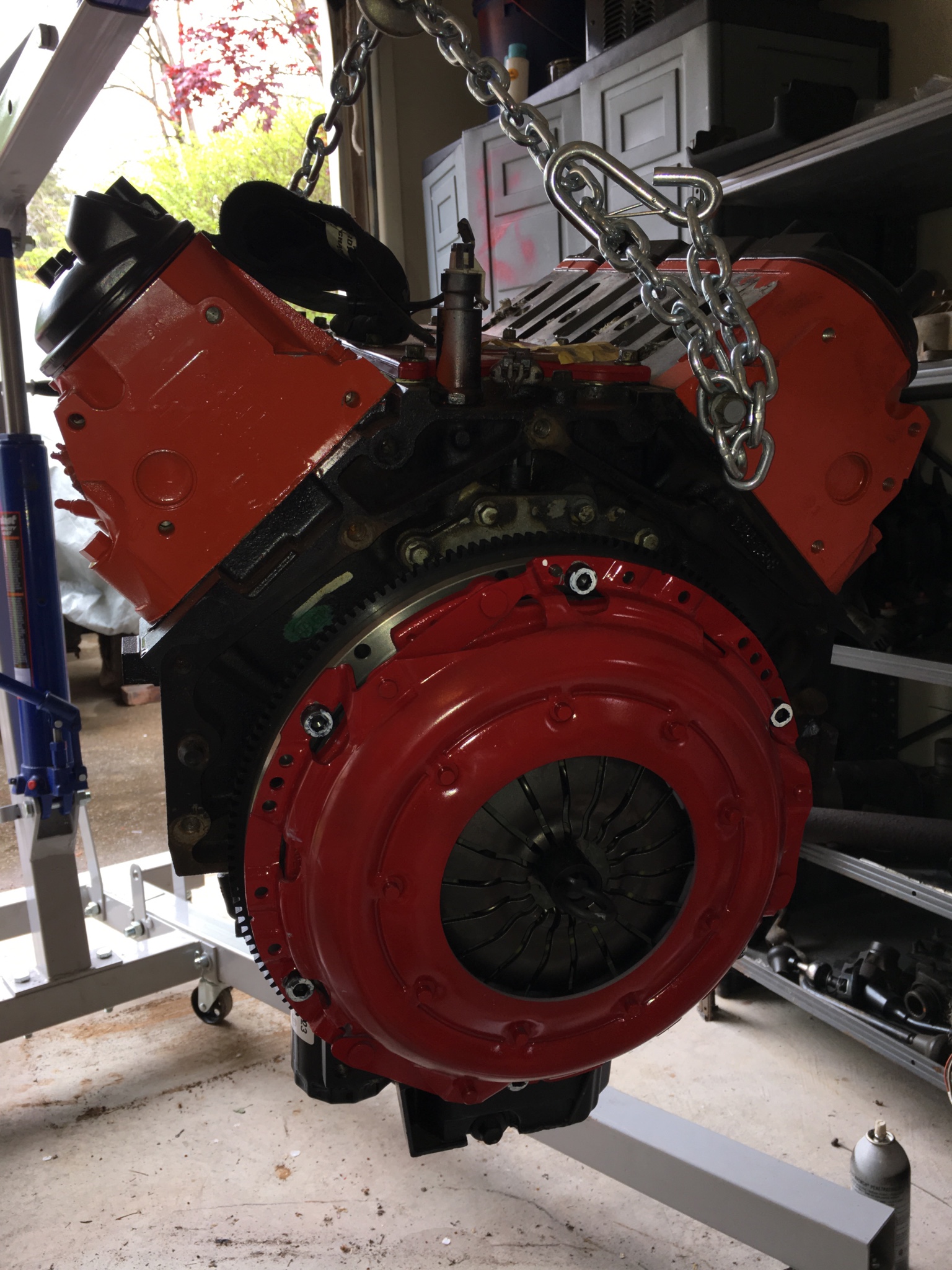

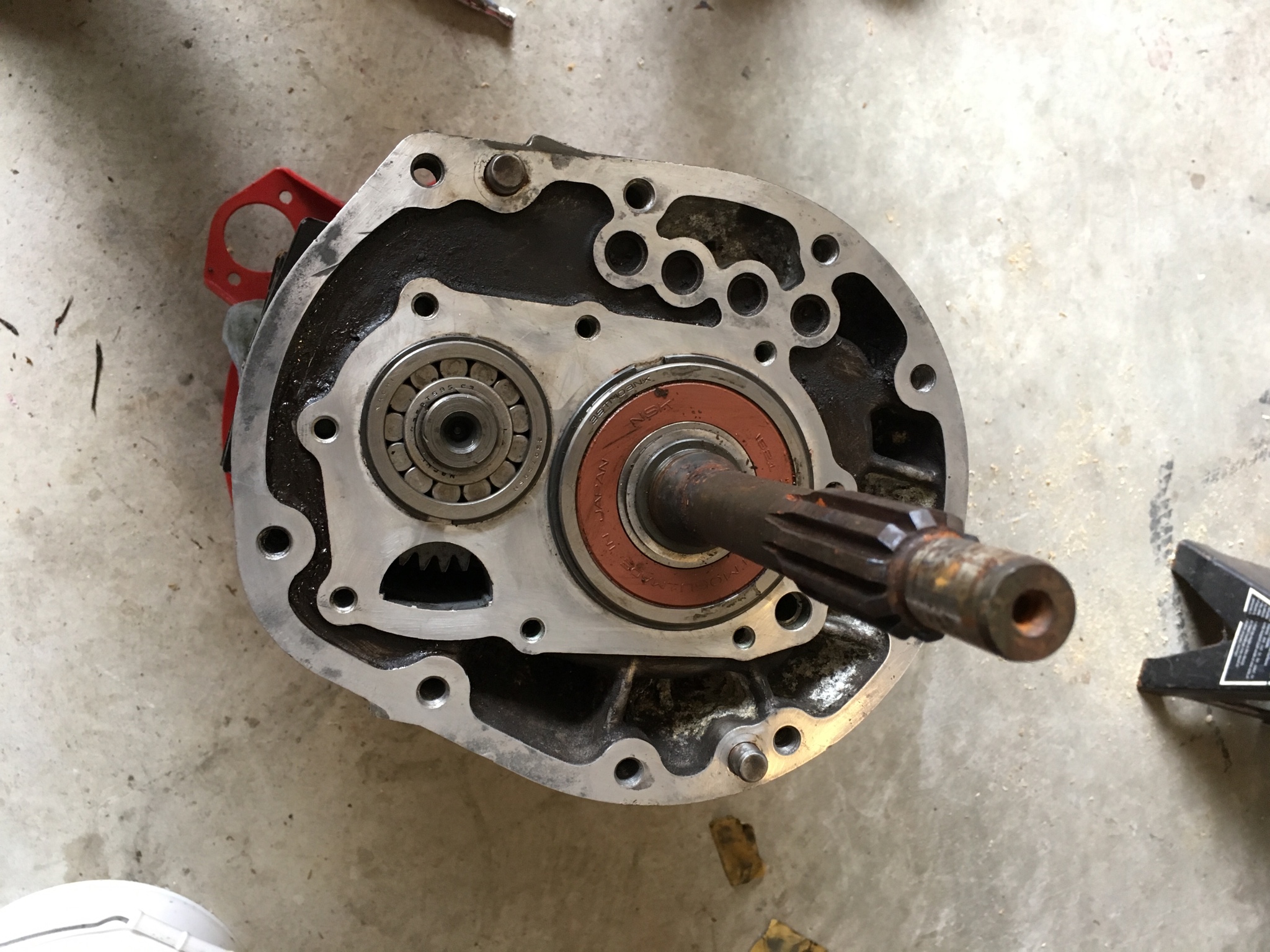

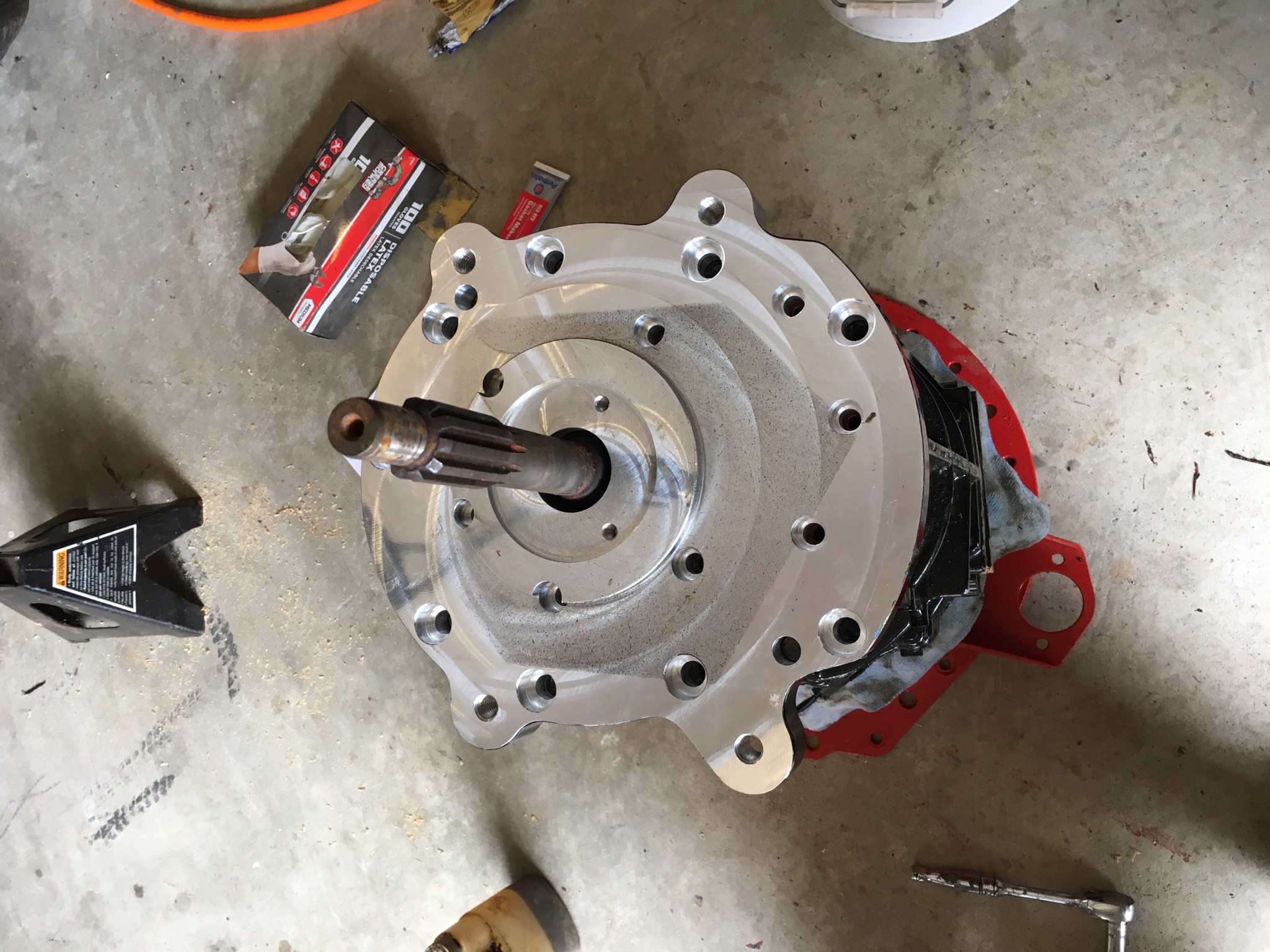

So with the TOB pulled all the way back to the trans you have 3.87" from BH face to TOB face? Is that with the fork installed?

but you don't want the slave coming off the sleeve. You will need to take some more measurements here to find your problem, but from the sounds of it the sleeve is too short. The TOB sleeve should extend to or even inside of the clutch fingers when the trans and engine are mated.