ckruzer

Infidel

- Joined

- Jul 2, 2015

- Location

- asheville nc

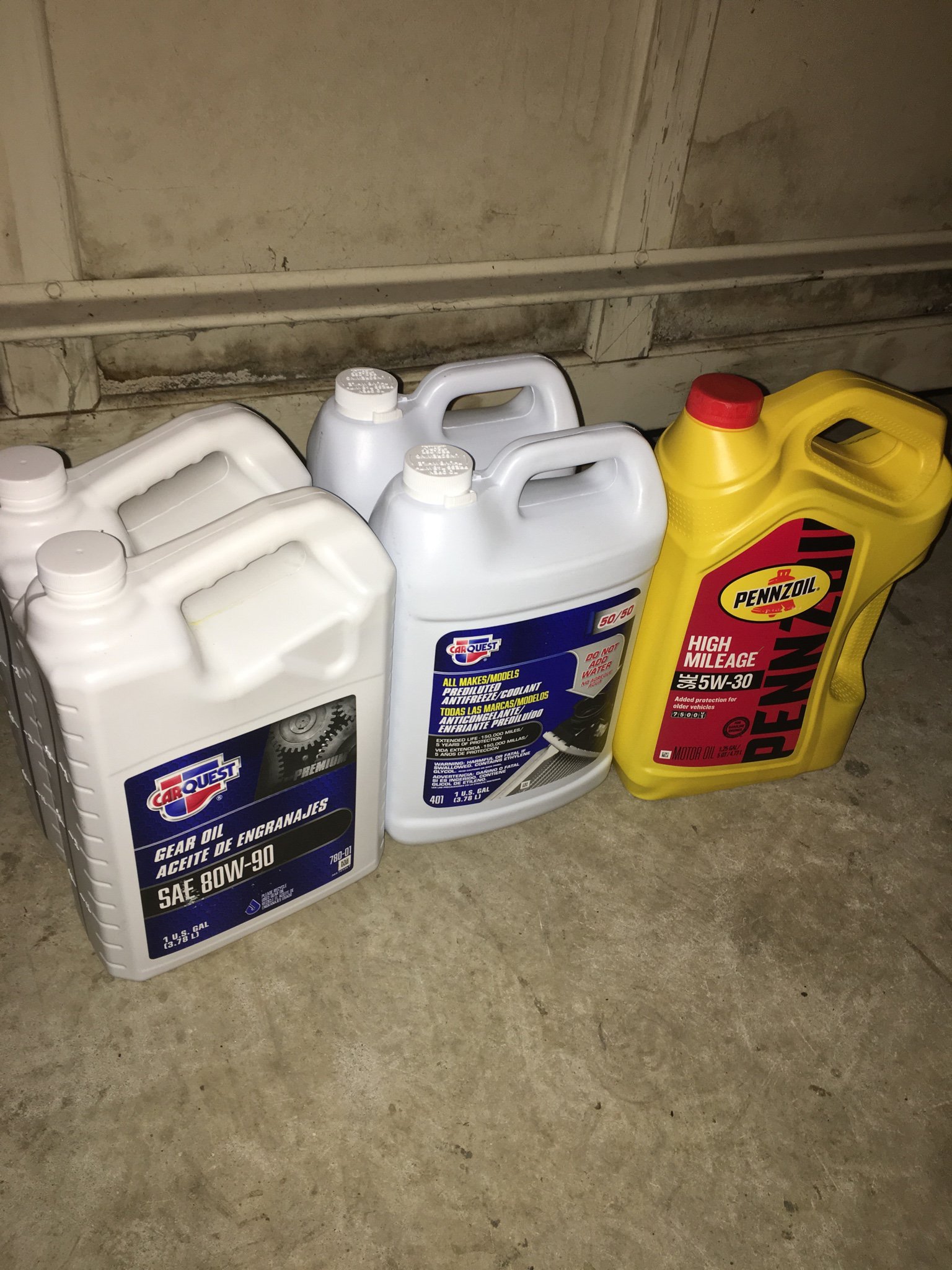

Ordered: Prothane 1” BL. EGR/EVAP Block Off Kit. Block Hugger Headers. OEM Starter. New OP Sensor. Alternator. 3 core Aluminum Radiator. Fan.

Looking good!

While a flat belly is helpful, 2" drop is not going to kill you. Remember, a stock ls oil pan hangs way low.

Put it inside the frame and 45 a tube down and then notch it to the main tube

I've got a notcherThat is a good point. I will have to address that in the future. But im more worried about crawling over a rock and it smashing an aluminum trans/tcase...

That is a great idea and would allow for a skid plate to still be easily made (with a drop). the 45 piece of tubing mayyyy be outside my very limited welding/fabbing skills. Haha.

You don't need bushings on the crossmember as well as the rubber tranny mount. That's redundant.

Toss the OEM trans mount in the garbage. Cut a piece of flat place and drill the holes to mount the plate to the trans. Mock up the new crossmember and then see how to attach it to the aforementioned plate.

Or go the easy route like @XJsavage said and lose the belly clearance but still keep a flat skid, just a little lower than planned.

I did the same on 2 YJs in the past. Did just what I described and they both worked flawlessly.

Simple tabs on both frame rails just like you propose. Then notched the tube for the bushing sleeves. Finally I cut slits in the 2 halves of the crossmember tube and slid them over the plate and burned them in.

I don't, it's been a few years back.

I really just cut slits out of the tube so the plate could fit in it. Then welded it up.

I notched the tubes to fit the frame side bushing sleeves like normal.