iwaxmyjimmy

College Web Wheeler

- Joined

- Mar 10, 2007

- Location

- Greenville NC

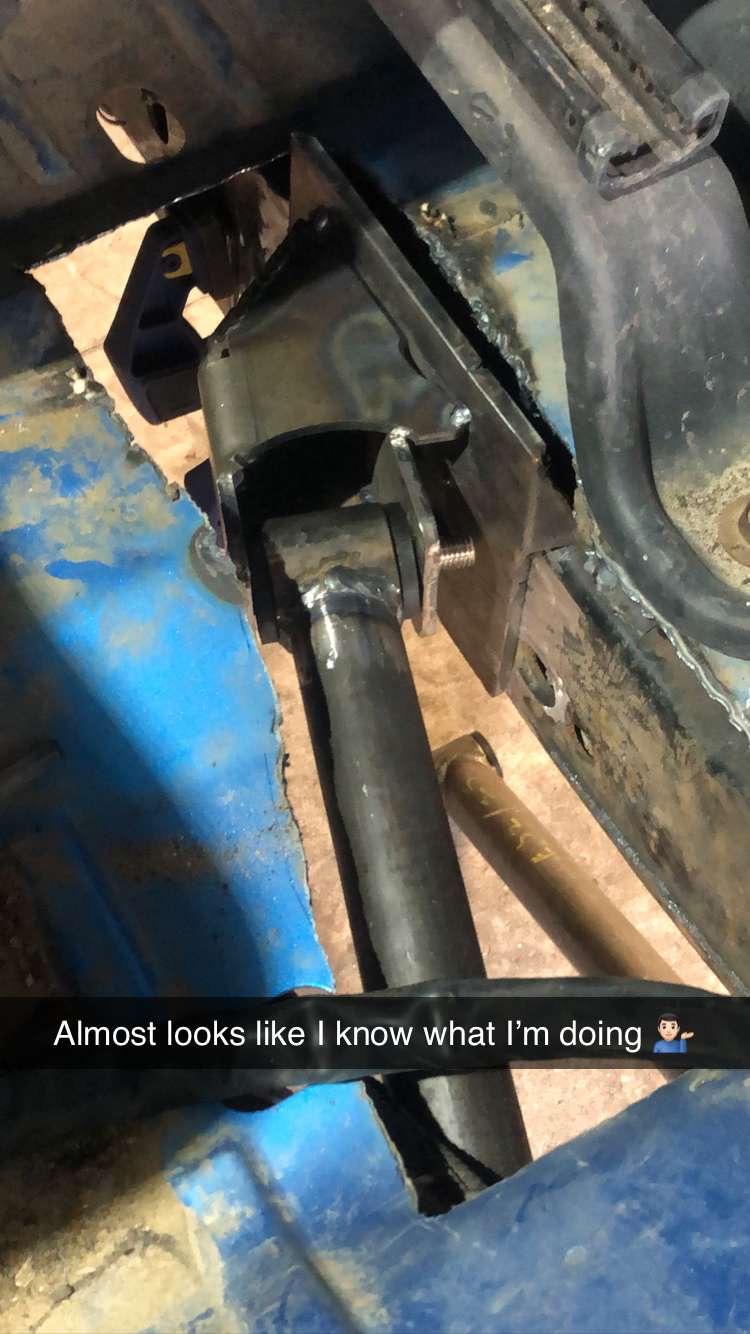

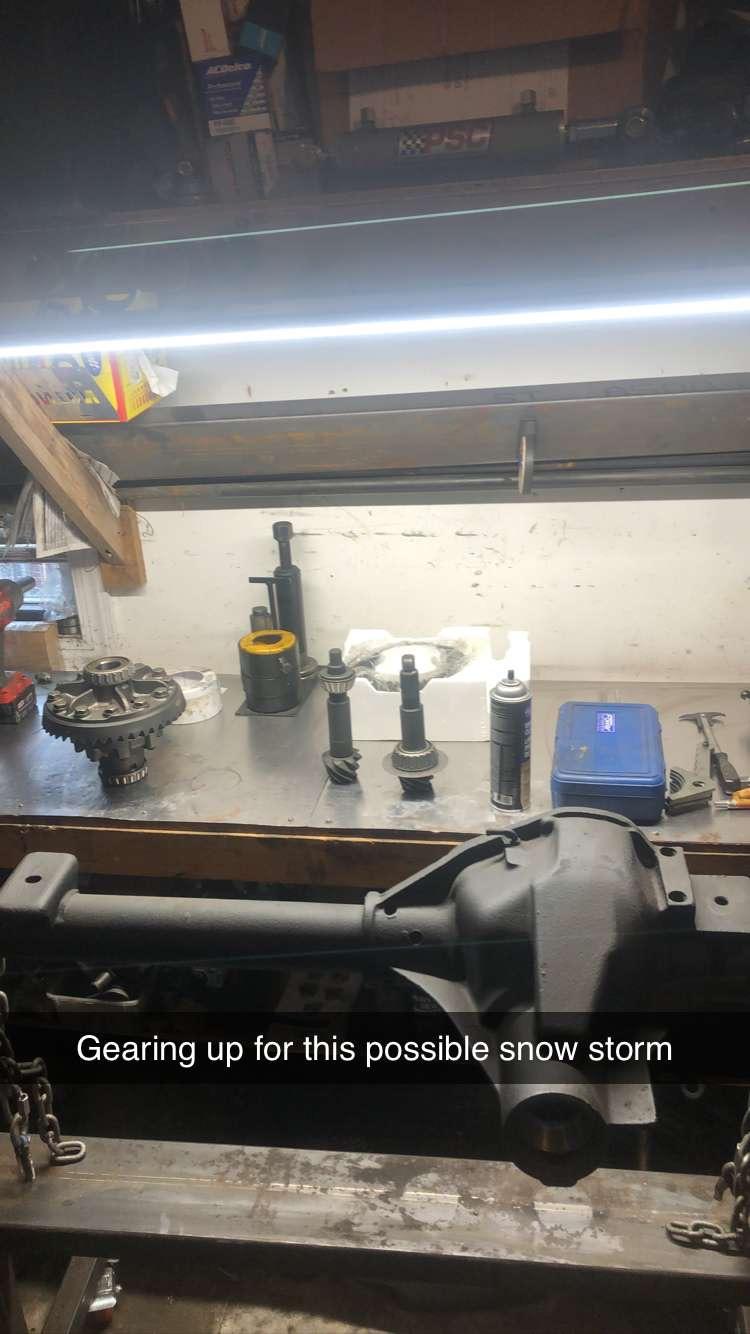

Well I still haven’t finished building that front 60, kind of hit a lump in the road because I need to buy some king pins and lower kingpin pin caps. The king pins were a little more pitted than I thought they were initially and, same for the lower caps which came out with some bearing and prying. And with holidays coming I was like screw it I can’t keep dumping money in this right now. Lower kingpin bearings came apart and were rust covered.

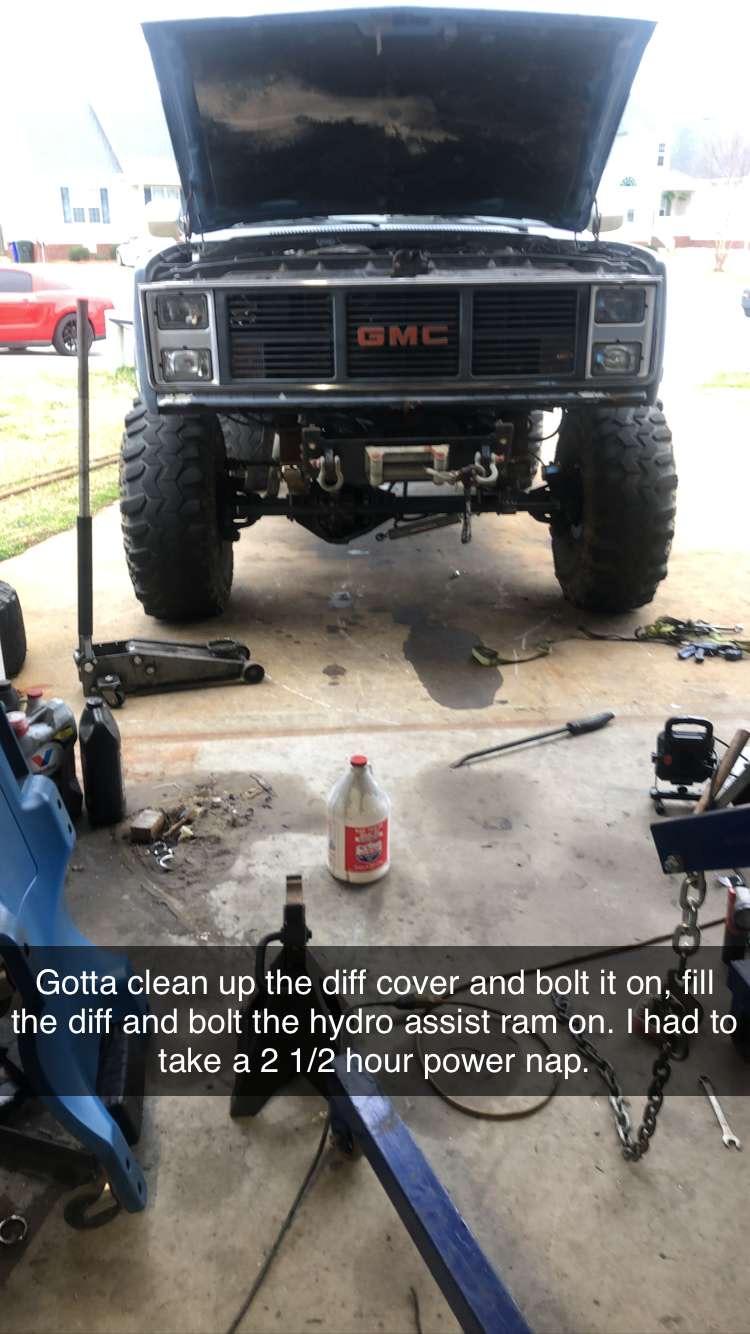

Tune seems spot on, how ever even with 8 gallons of fuel, I’m still having some delivery issues. Sitting on the couch watching dirt every day, I became curious if I mistakenly put a 25 gallon tank sending unit in my 31 gallon tank. I can’t remember nor do I have the box or anything. So I need to verify that, the 25 gallon tanks are about 2” or so deeper so would make more sense than the baffles in tank not working as directed. And a $85 sending unit would be much easier on the wallet than $250+ to do a hydra mat.

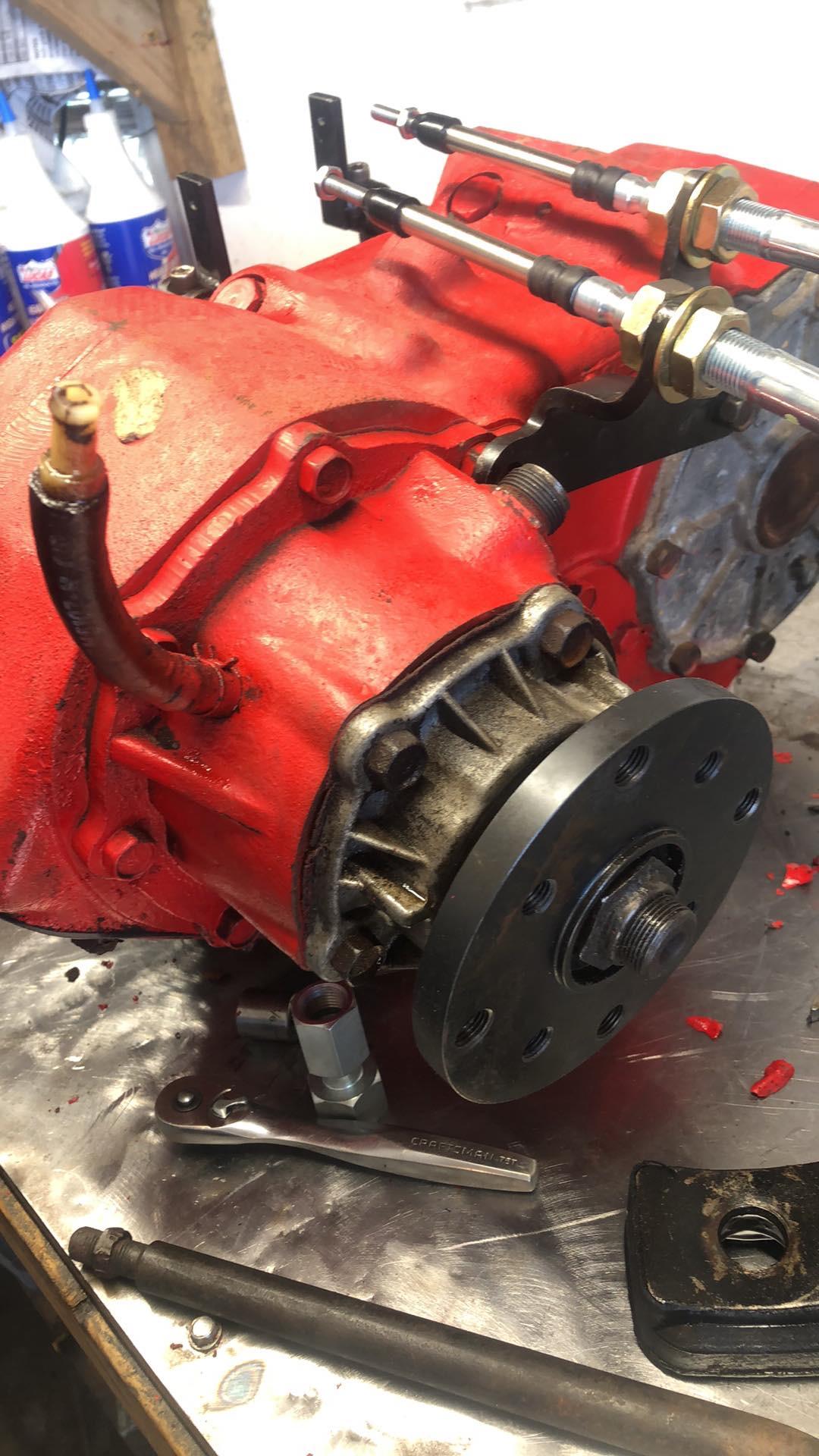

But on a good note the 5.38s have really made it a pleasure to drive around town, but yeah she’s screaming 3k rpm at 65. Needs an nv4500 hopefully I can fine a decent one, hopefully and earlier model so I can keep a deep granny gear. Worse case I’ve got 32 spline np208 that I’ve found some info you can take a dodge one, swap out the main shaft, shift cam, and rear case half to make a SYE. That added low range would be nice.

Right now I’m at a 69:1 crawl ratio which isn’t too bad, seems to just chug along in low range. I know I’m going to want deeper if I plan to step up to some bigger tires. So either the 208 or I’ll have to shit out some funds for a magnum/black box.

Tune seems spot on, how ever even with 8 gallons of fuel, I’m still having some delivery issues. Sitting on the couch watching dirt every day, I became curious if I mistakenly put a 25 gallon tank sending unit in my 31 gallon tank. I can’t remember nor do I have the box or anything. So I need to verify that, the 25 gallon tanks are about 2” or so deeper so would make more sense than the baffles in tank not working as directed. And a $85 sending unit would be much easier on the wallet than $250+ to do a hydra mat.

But on a good note the 5.38s have really made it a pleasure to drive around town, but yeah she’s screaming 3k rpm at 65. Needs an nv4500 hopefully I can fine a decent one, hopefully and earlier model so I can keep a deep granny gear. Worse case I’ve got 32 spline np208 that I’ve found some info you can take a dodge one, swap out the main shaft, shift cam, and rear case half to make a SYE. That added low range would be nice.

Right now I’m at a 69:1 crawl ratio which isn’t too bad, seems to just chug along in low range. I know I’m going to want deeper if I plan to step up to some bigger tires. So either the 208 or I’ll have to shit out some funds for a magnum/black box.