iwaxmyjimmy

College Web Wheeler

- Joined

- Mar 10, 2007

- Location

- Greenville NC

Well either axle I can make it happen so that's no biggie. Main thing is the bolt pattern. I've got an 87 k5 on 1 tons so I'd love to be able to just swap tires between the two and rollers. I could just run spacer adapters on the Ford 1 tons but I'd rather not.

Something I've toss around was running just adapters on the rear wheels after a while I'll cut and plate the bottom of a 14 bolt using one of those fancy shave kits. I know if I had a bolt in sterling rear for a JK I could resell it it for $1k Bc most people

Don't have welding capabilities and the JK crowd appeals to that.

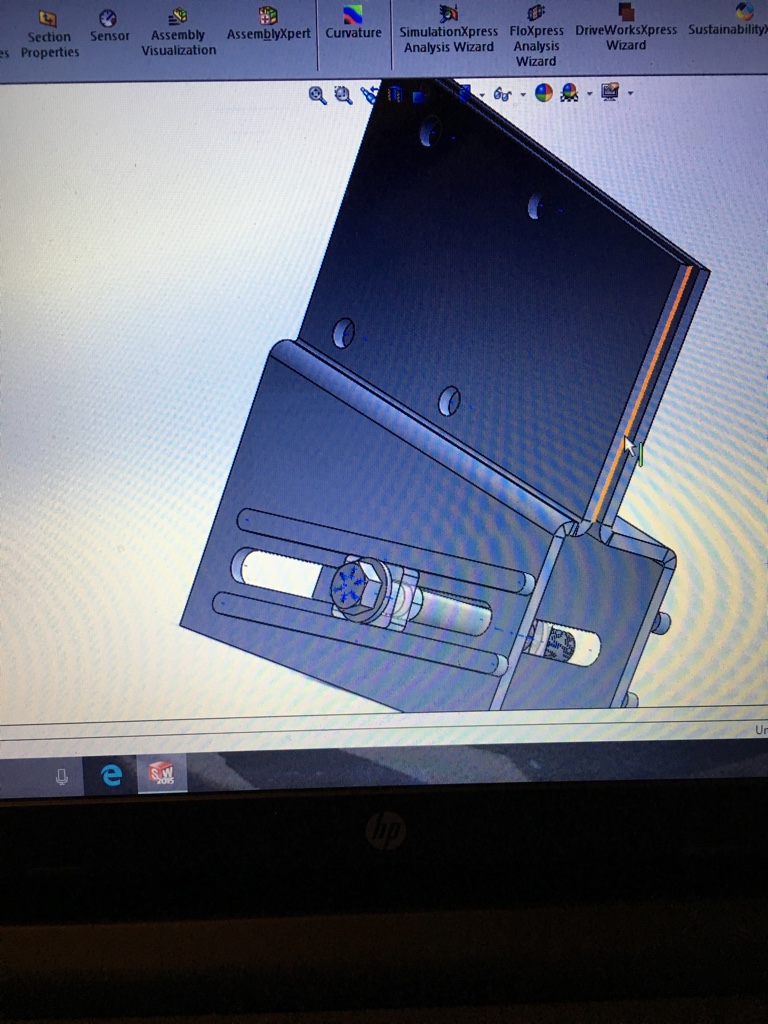

I'm cutting the frame in front of the motor mounts, I've done a solid works drawing of the the frame how I want it to be. I'm moving the steering box forward 4 inches, making it so I've got 3" more of uptravel clearance for my front axle, and have a better approach angle.

4" up front and not sure yet on the rear. Might stay stock till I double triangulate the rear but I could do 6" and not comp cut it

Sent from my iPhone using Tapatalk

Something I've toss around was running just adapters on the rear wheels after a while I'll cut and plate the bottom of a 14 bolt using one of those fancy shave kits. I know if I had a bolt in sterling rear for a JK I could resell it it for $1k Bc most people

Don't have welding capabilities and the JK crowd appeals to that.

I'm cutting the frame in front of the motor mounts, I've done a solid works drawing of the the frame how I want it to be. I'm moving the steering box forward 4 inches, making it so I've got 3" more of uptravel clearance for my front axle, and have a better approach angle.

4" up front and not sure yet on the rear. Might stay stock till I double triangulate the rear but I could do 6" and not comp cut it

Sent from my iPhone using Tapatalk