iwaxmyjimmy

College Web Wheeler

- Joined

- Mar 10, 2007

- Location

- Greenville NC

Could pull the distributor and spin the oil pump with a drill and see what it does...

That's what I'm doing tomorrow after I change out the filter, I've got a priming tool

Could pull the distributor and spin the oil pump with a drill and see what it does...

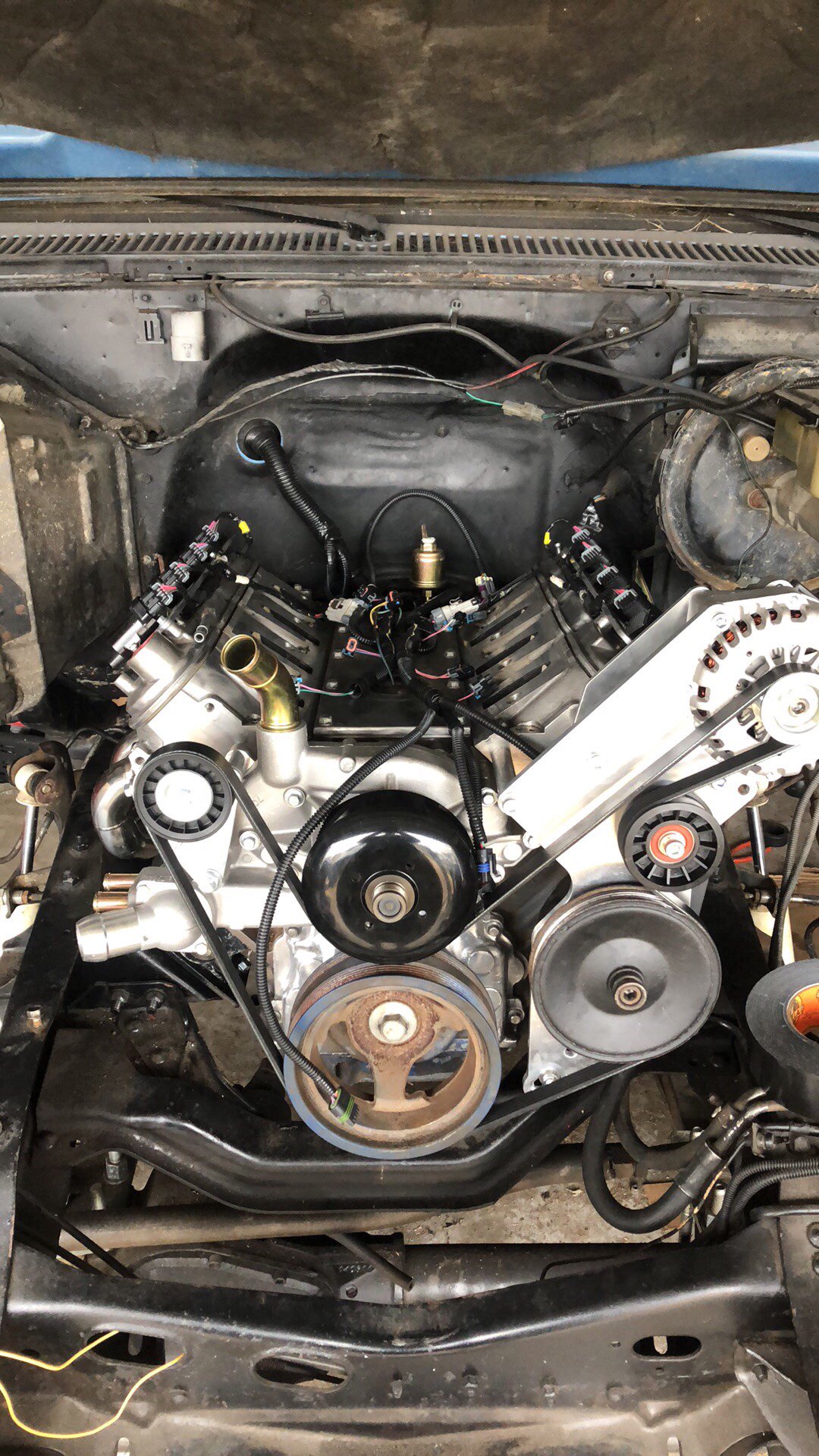

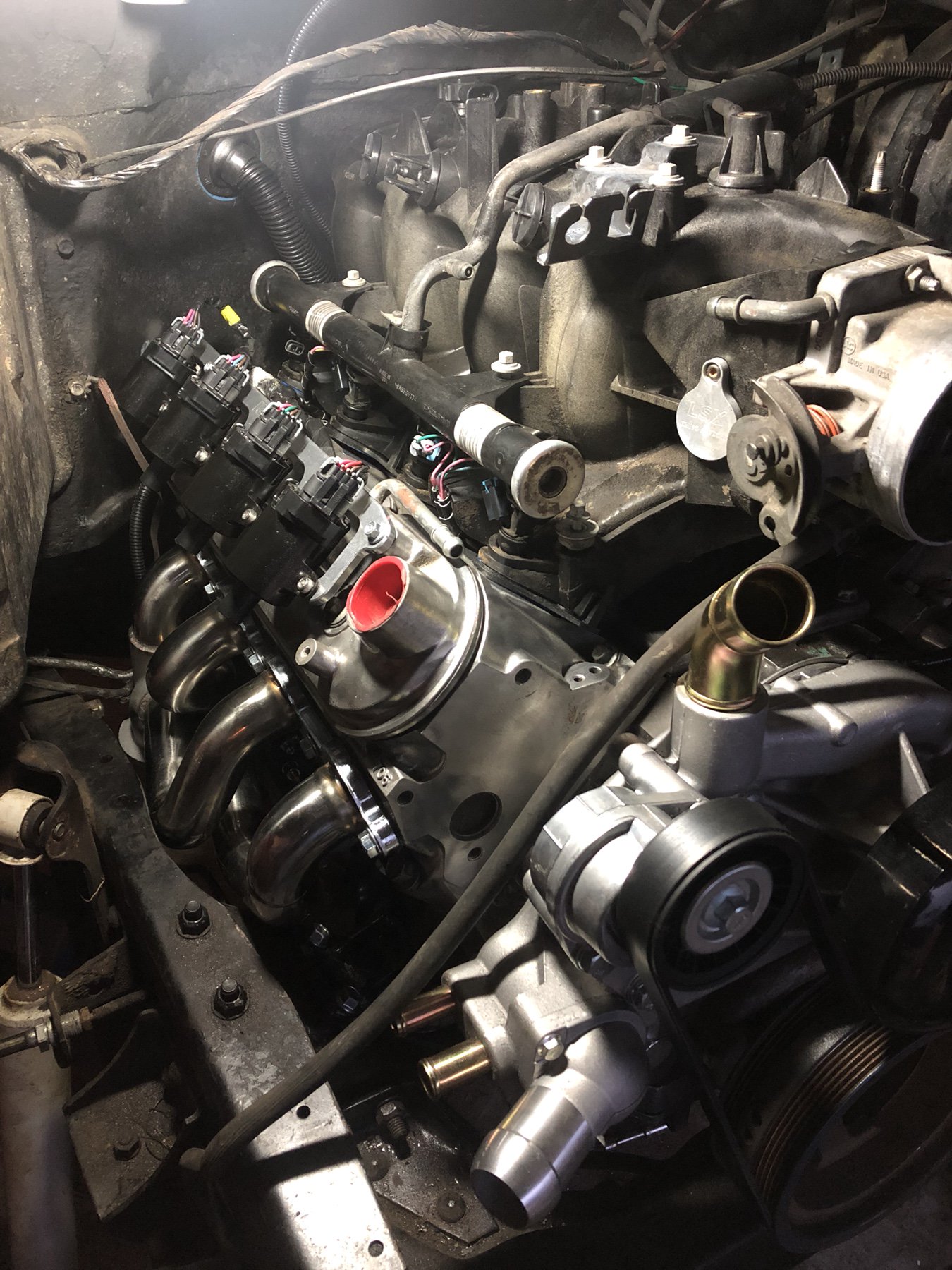

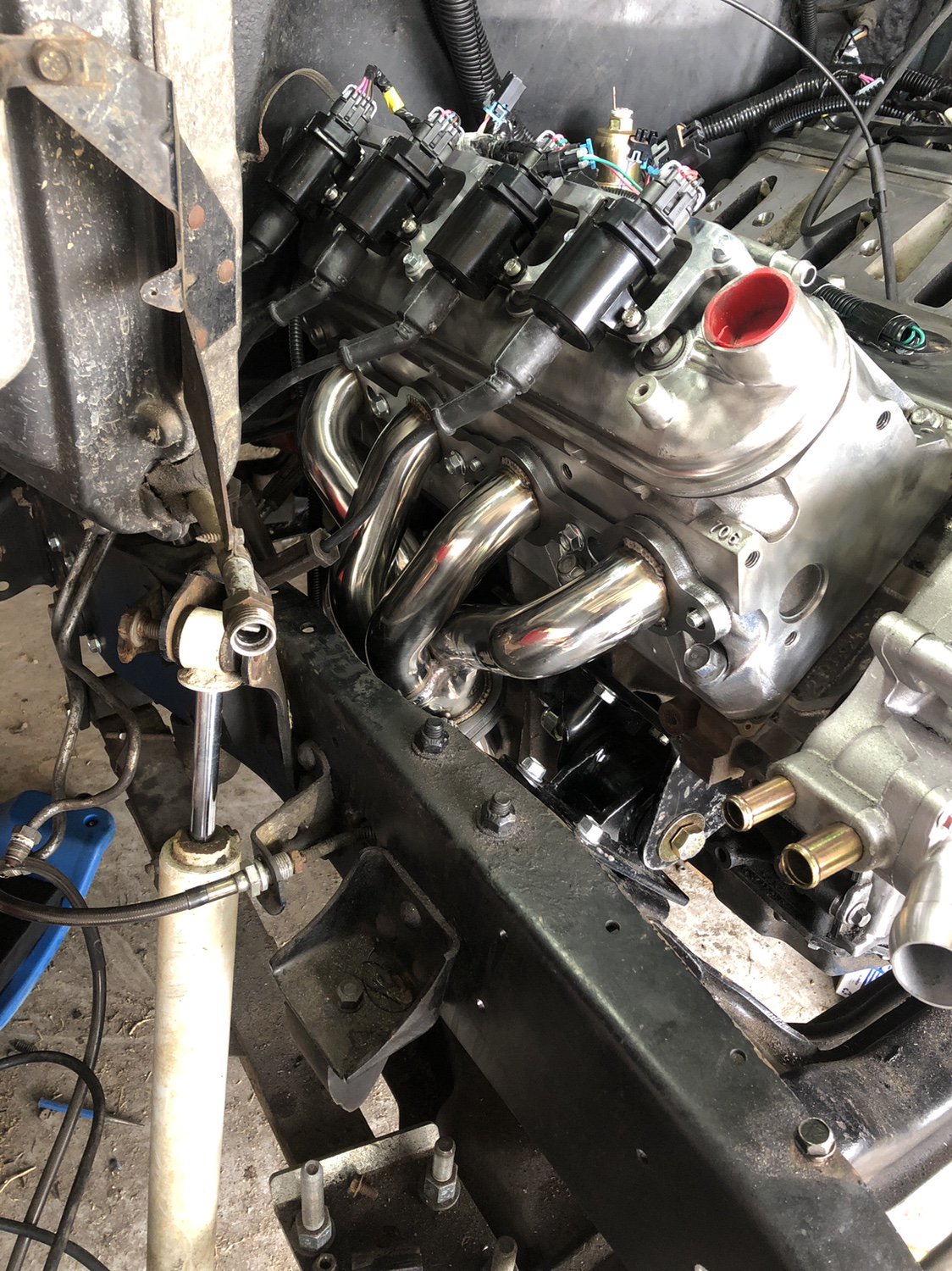

If they'll fit, I'd get longtubes for sure...otherwise I'd just use stock manifolds.

Also, I have some intakes and other stuff laying around. Let me know what you need.

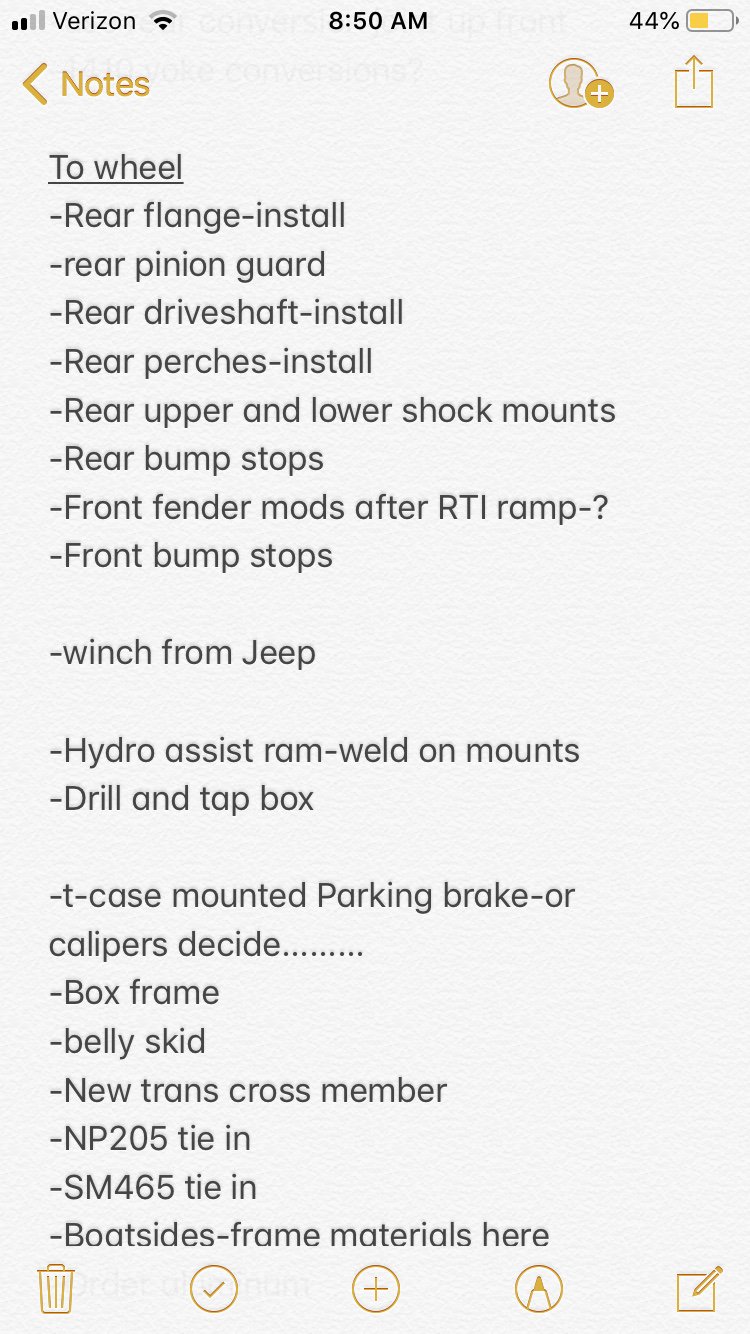

In Greenville, Dillon Supply is going to be the easiest to deal with for DOM.

Do you have a DC stick welder? if so, just get a scratch start tig setup to learn on; you won’t have thousands of $ tied up in a rig up front and can learn easily. Then pick up a good tig later once you get the hang of it and know more of what ya want. Hell, we do X-ray quality welds with scratch start tig rigs all day long.

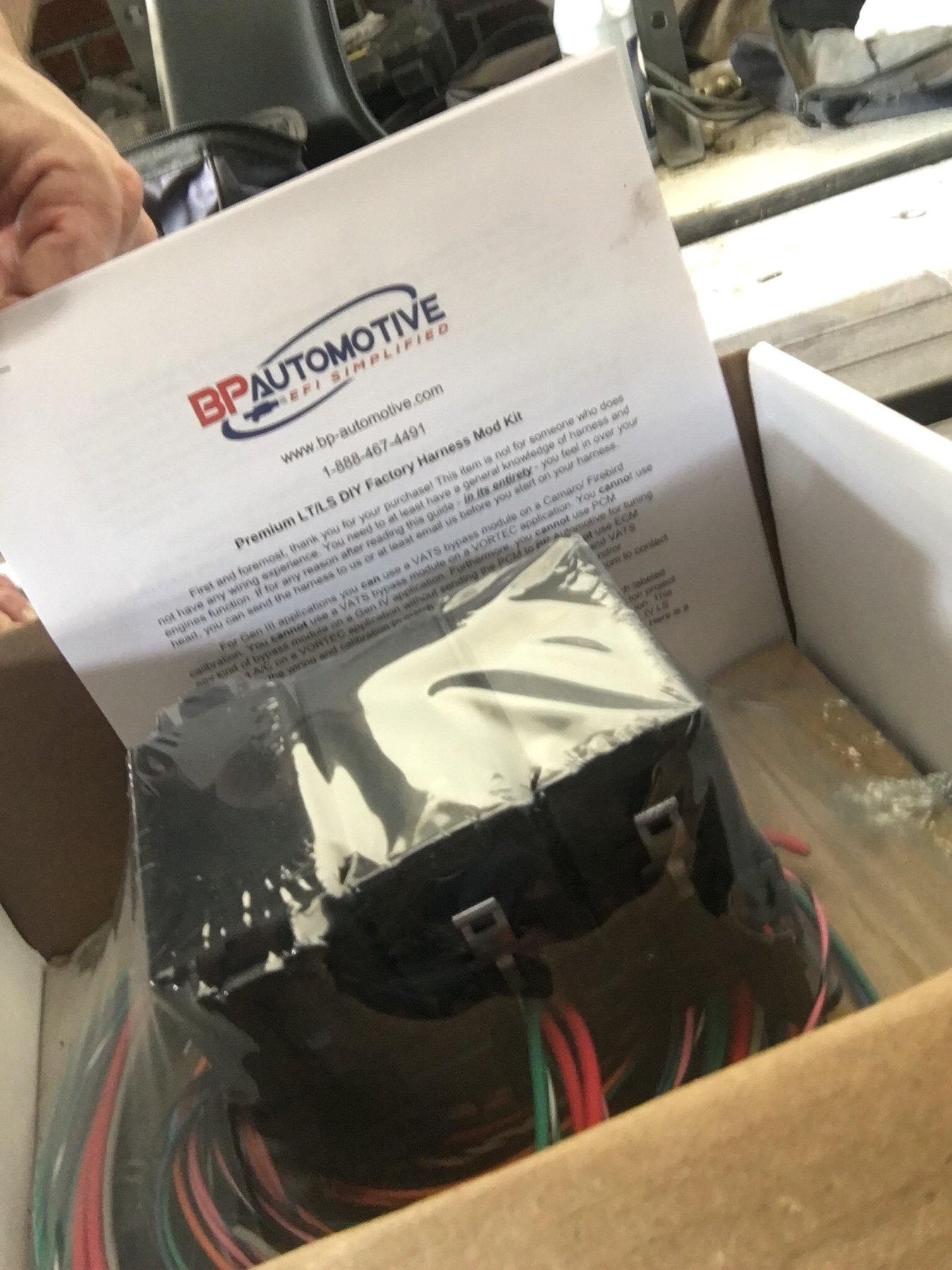

Oh, and I have a lot of leftover Delphi weather pack plugs of various sizes and pins from my buggy if you need any. I’ll keep a couple for spares and you can have the rest if you need them.

And I think I have some leftover 3” V bands and flanges if you need any. And a whole roll of exhaust wrap.

I’ve already been buying up a lot of that stuff so I may take you up on that. Wasn’t gonna run exhaust wrap on the k5 Bc I have a feeling it’s gonna get muddy here and there. Your buggy all buttoned back up?

I need to get up to G-Vegas one day and check that rig out.

Mine has got a long way to go. Robs though I may try to sneak over there this weekend if I get a chance.