Wow...been a while. Between work/school/weddings, not much as gotten done in the month of May. I ordered a set of spring perches from

@Barnes 4wd and they showed up today. The plan will be to SOA the front axle which should level everything out adequately. I will have to modify the perches to fit around the cast housing on the passenger side but it should not be a big deal. Last weekend I decided to tackle the skidplate. My plan was to remove the original crossmember/skid and redesign it so that I have a somewhat flat belly. Here's the original skid plate.

It hung down quite a bit and added a lot of weight. Fired up the sawzall and with a pair of fresh Lennox Torch blades it came right out.

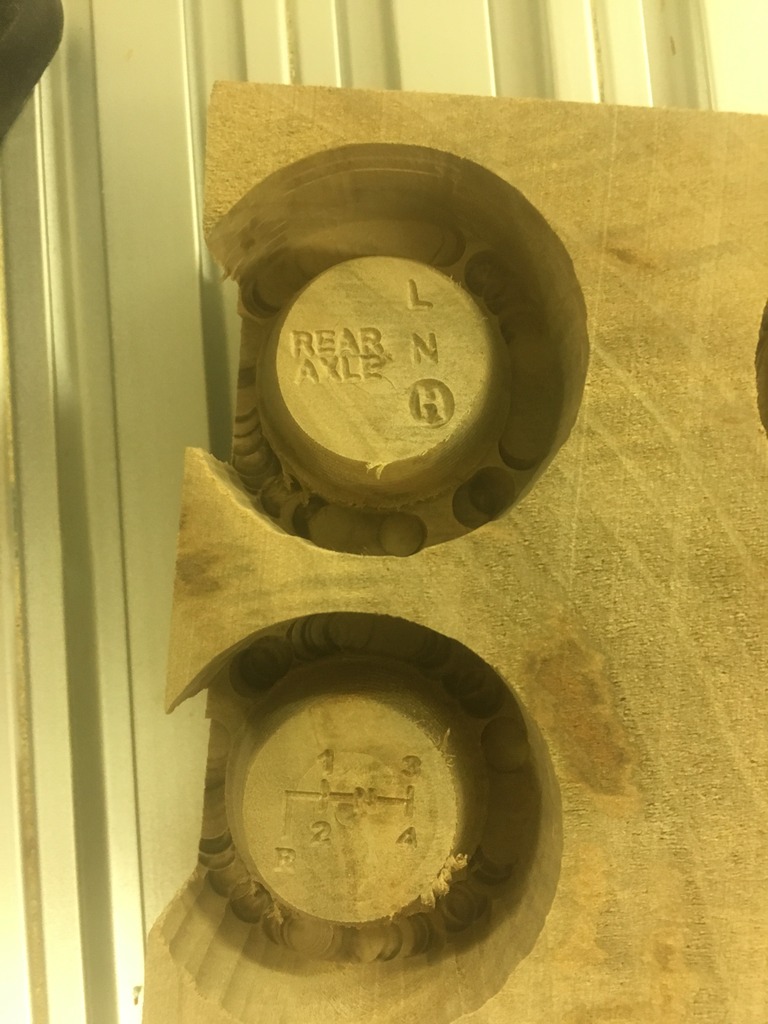

Now that the old one is out of the way, its time to build something functional. I am going to clock the D300. This will allow me to stuff the drivetrain up inside the framerails, better belly height etc. To do this I have to go from twin sticks to cable shifters. Luckily

@justjeepin86 had a pair of cables and the bracket that I could use. I'll fab up a simple shifter design in the future. While I have the D300 out of the jeep, I'll upgrade the balls/springs so it won't have the tendency to pop out of gear.

My crossmember will be built out of 1.75"x.120" DOM and should be simple enough to bend up(thanks

@rockcity for the bender). I am planning on making two crossmembers. One will serve as the transfer case mounting point. The second one will be behind the rear tailshaft of the D300 and will be tied into the first one. A simple hoop will be added to the front crossmember to protect the transmission. The crossmembers will be welded together but will be bolted to the frame so that removal is easier. Some areas of the crossmembers might get plated as well depending on final design/layout. Lastly, the transfer case mount will be cut down so that the crossmember can be as high as possible. The transfer case mount already has a poly bushing in it so I will not need to put bushings on the frame mount. As always, if anyone has a better design or idea, please speak up