awheelterd

Well-Known Member

- Joined

- Oct 18, 2007

- Location

- Kenly, NC

Technically probably so

So, a condom with a hole in it is better than none at all??

Technically all condoms have a hole in them, kinda like all socks have a hole in themSo, a condom with a hole in it is better than none at all??

Technically a condom can be reused. Just turn it inside out and shake the fuck out of it.At better analogy is a used condom compared to none at all. It might protect you,, it might also have the clapper left over from the prior user

Well dang, learn something new everyday lol! Dang dude why u have to go getting all mathematical and stuff, hahaha. Well its on there and ill find out next weekend how it works. Sure feels good wearing both of them to say the least lol.Seat belts are located very precisely to control the direction of force and deceleration applied to the body.

A belt located improperly can cause spinal compression or worse even in a low speed impact.

You are literally safer being throw around inside the cab than being restrained by improperly located restraints.

I am not saying yours are wrong or improper, haven't seen them so no clue, just making a generic statement for education purposes that surprised me when I learned it.

Technically all condoms have a hole in them, kinda like all socks have a hole in them

Technically a condom can be reused. Just turn it inside out and shake the fuck out of it.

Sure feels good wearing both of them to say the least lol.

Marty79, all joking aside. You seem to have a good attitude about life in general. Not many people would post their first attempt at a cage on a form, let alone take the ribbing you have over the years. In my opinion the best way to learn is to do, and learn what you can from the experience.

I would guess I am trying to say, no one knows everything from the start. As long as you are learning through out life, then I would say you have lived well......

Easy now, he said "first cage" lol. Nah I've learned a bunch from people here and other places. I've learned enough to know "how" to properly do something...on my rig it just doesn't make it that far haha... I guess if I wasn't such a cheap frugal butt I might but I can't help it.What is the definition of insanity???

Doing the same thing over and over expecting different results?

I'm not sure any learning has actually taken place in the last year or two. Hard work, yes. Learning, no.

Easy now, he said "first cage" lol. Nah I've learned a bunch from people here and other places. I've learned enough to know "how" to properly do something...on my rig it just doesn't make it that far haha... I guess if I wasn't such a cheap frugal butt I might but I can't help it.

If I had 1000 budget for my jeep add-ons, 600 worth of cage material or more WOULD NOT ever be in that budget lol, 200 would be for cage and 800 for all kinds of other brewed up mods lol. Can't help it, that's just me. I could seriously make 60K yr and still would feel this way, except the whole cage would've been finished and 5 point harness added.

but it makes perfect sense to wheel balls out

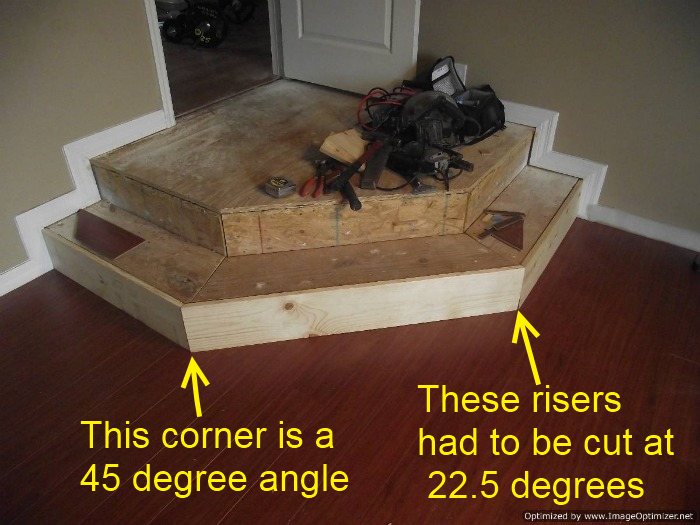

Hey can u briefly explain this a little to help me figure it out. I'm guessing you're referring to all my angles being a 90 which isn't good? I did it for simplicity with X bracing in mind once I get more material.knowing how to cut a 22.5* angle would have helped you a lot on your cage..

Hey can u briefly explain this a little to help me figure it out. I'm guessing you're referring to all my angles being a 90 which isn't good? I did it for simplicity with X bracing in mind once I get more material.

Ok sorry guys I get the angled cut but still don't get the main reasoning, not trying to be difficult (maybe I'm little slow at learning but I don't get the clear message)thanks

The main reasoning is - you need more things at a 45 degree (or other non-90) angle, for strength.Ok sorry guys I get the angled cut but still don't get the main reasoning, not trying to be difficult (maybe I'm little slow at learning but I don't get the clear message)thanks

That's what I was not getting, makes sense. Thanks for clarifying that!If you're asking why you need things at angles, go try this experiment. It will be very education.

Go but some EMT or similar cheap tubing. Weld 4 pieces, maybe 3' long, into a square.

Now, take your square, go up to the top of a building and throw it off, so that the corners or side hit the ground like a wheel (NOT flat on the ground).

Observe how it bent. $5 says it will be a diamond-shaped parallelogram.

Now get more tubing and make the same square again, but this time, put 2 extra bars making an X in the middle, and throw that.

Notice how much stronger it is.

Now also go get 3 pieces and make a triangle, and throw it, and again compare to your square.

*technically* you CAN make a 45 joint by just cutting 1 at 45 and the other at 90.

It's going to need a 5.9 Cummins in it to pull all the weight. But 1/4 wall DOM will keep ya safe. LolI feel like this jeep needs that giant cat radiator you had on the tramp xj... something maybe a like a old hummer hood I dunno get creative find a old ass willys hood to chop up and have pins in? lol I'm trying to open up your mad max creativity haha