What a Great time. First I am very thankful for all the family and friends that helped me get ready for this year's KOH race.

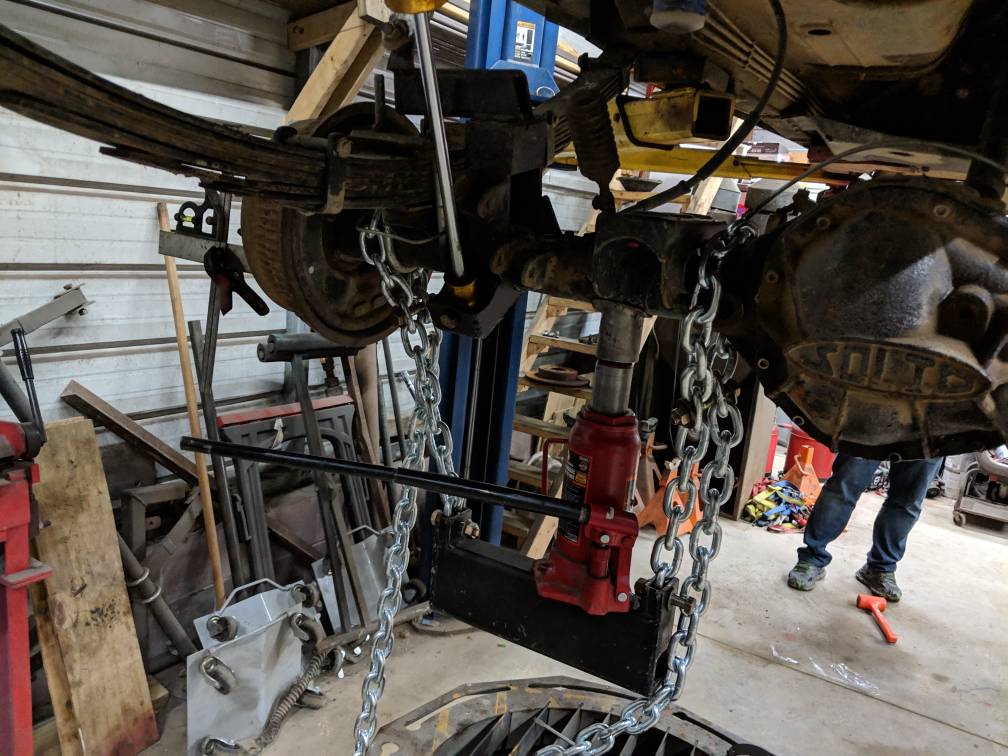

We spent countless hours in the shop at home prepping the car and it was all worth it. We ran some tests runs in the whoops and we can run 45 in the whoops and it is super smooth. Can't complain doing that in an old beat up Jeep Cherokee on leafs springs.

We did have a few issues we had to fix before race day and I am very happy we found them all before the race started. We took apart the power steering I think 5 times till it was all correct. We adjusted rear air bumps which made it even smoother and faster.

Race recap: we started about Midway in our class about 8:32am and the Jeep did great all the way to the first pit. We were able to hold our own this year and Jeep felt great until about 1 mile out of pit one. We pulled in and the found lower control was loose so the pit guys tightened it up and put a take weld on it. We took off and again no big issues until close to pit 1 B where the pit crew was ready with welder and pit more weld on the arm, filled up the fuel and tightened the wheel lugs.

We set off to the main pit and again Jeep was great. We came into main and just drive straight through and back into the desert.

By this time we had some noises but nothing we were to worried about until we heard some clanking and I noticed the front was not pulling. We checked everything but could not find anything visible that was broke. So we continued on until we came to a large rock and we found the front had no pull at all. We believe we destroyed the front locker or Carrier. (we will find out when I get home and rip it apart)

At that point we just helped 6 other teams get up the rocks and continue on. We eventually built a ramp out of rocks and launched the Jeep up and over. As we created the top of the hill I made the decision to pull from the race as we still had 4 more Rock trails and with no front pulling it most likely would not have made it to the finish.

We ended up doing 106.5 miles in about 5.5 hrs. Heck of a lot better than last year. I am 100% sure if front held together we would have had a finish this year. Oh well maybe next year.

Thanks to:

My wife Jessica and my kids

Doug Johnson

Kevin Shortt

Rick O'Shea

John Herr

Ron Watson

Martin Thiele

Dave Henson

Joe Murphy

Scott MacIntyre

Russ MacIntyre

Steve Milano

Josh Olevsky

Justin Barney

Ken, Donna and kids

Also thank you to my sponsor support:

Ironman4x4Fab.com

East Coast Gear Supply

Rugged Radios

Rusty's Off-Road Products

PSC Motorsports

BFGoodrich Tires

Impaks Garage

Ultra4 Racing

King of The Hammers

#4620

Ultra4 KOH Fans

If you read this far, be on the look out for more pictures I will post over the next week.

We spent countless hours in the shop at home prepping the car and it was all worth it. We ran some tests runs in the whoops and we can run 45 in the whoops and it is super smooth. Can't complain doing that in an old beat up Jeep Cherokee on leafs springs.

We did have a few issues we had to fix before race day and I am very happy we found them all before the race started. We took apart the power steering I think 5 times till it was all correct. We adjusted rear air bumps which made it even smoother and faster.

Race recap: we started about Midway in our class about 8:32am and the Jeep did great all the way to the first pit. We were able to hold our own this year and Jeep felt great until about 1 mile out of pit one. We pulled in and the found lower control was loose so the pit guys tightened it up and put a take weld on it. We took off and again no big issues until close to pit 1 B where the pit crew was ready with welder and pit more weld on the arm, filled up the fuel and tightened the wheel lugs.

We set off to the main pit and again Jeep was great. We came into main and just drive straight through and back into the desert.

By this time we had some noises but nothing we were to worried about until we heard some clanking and I noticed the front was not pulling. We checked everything but could not find anything visible that was broke. So we continued on until we came to a large rock and we found the front had no pull at all. We believe we destroyed the front locker or Carrier. (we will find out when I get home and rip it apart)

At that point we just helped 6 other teams get up the rocks and continue on. We eventually built a ramp out of rocks and launched the Jeep up and over. As we created the top of the hill I made the decision to pull from the race as we still had 4 more Rock trails and with no front pulling it most likely would not have made it to the finish.

We ended up doing 106.5 miles in about 5.5 hrs. Heck of a lot better than last year. I am 100% sure if front held together we would have had a finish this year. Oh well maybe next year.

Thanks to:

My wife Jessica and my kids

Doug Johnson

Kevin Shortt

Rick O'Shea

John Herr

Ron Watson

Martin Thiele

Dave Henson

Joe Murphy

Scott MacIntyre

Russ MacIntyre

Steve Milano

Josh Olevsky

Justin Barney

Ken, Donna and kids

Also thank you to my sponsor support:

Ironman4x4Fab.com

East Coast Gear Supply

Rugged Radios

Rusty's Off-Road Products

PSC Motorsports

BFGoodrich Tires

Impaks Garage

Ultra4 Racing

King of The Hammers

#4620

Ultra4 KOH Fans

If you read this far, be on the look out for more pictures I will post over the next week.