hunterdan

Well-Known Member

- Joined

- Apr 13, 2009

- Location

- Morganton,NC

HVAC wisdom needed.

We are at the point of doing HVAC and just thought I'd see what peoples thoughts are regarding our current plan.

After doing a good bit of reading reviews and searching HVAC forums we have decided we like the Bosch system.

Home is a single above grade floor with vaulted ceiling (17') and a walkout basement with open stairway between upper floor and basement.

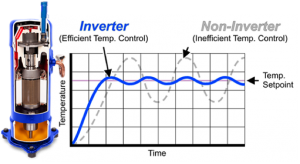

Bosch offers an inverter compressor heat pump in a 3 or 5 ton unit.Basically, the system does not run wide open when operating if not needed. It runs at a variable speed depending upon demand lengthening life of components and reducing energy demand. The contractor I'm planning to use plans to put the air handler/return above our closet upstairs. It will be a dual zone/split system with electric doors to upper and lower floor ductwork via upper and lower floor thermostats.

I know that every home needs calculations for "R" factors for walls,windows...but with the Bosch 3 ton unit it works with any home needing 1.5-3 ton unit. Mine needs about 2.5-3 so it will be the 3 ton.

My main concern now is that the contractor correctly figures the cubic feet per minute and such for each room or living area and the correct placement of the return.

He says he plans to install one return upstairs. It will be about 2/3 up the 17' vaulted wall dividing our living room from our bed/bath area. He also plans to install the registers for heating/cooling on that same wall....one about 8' away on each side of the return and a few feet lower on the wall.

Here's a link to a thread here on the forum which better describes the home

House build start to finish

Reason for one return is that the stairway is open to the basement

Any opinions appreciated as this system will be installed next week.

Thanks, Dan

We are at the point of doing HVAC and just thought I'd see what peoples thoughts are regarding our current plan.

After doing a good bit of reading reviews and searching HVAC forums we have decided we like the Bosch system.

Home is a single above grade floor with vaulted ceiling (17') and a walkout basement with open stairway between upper floor and basement.

Bosch offers an inverter compressor heat pump in a 3 or 5 ton unit.Basically, the system does not run wide open when operating if not needed. It runs at a variable speed depending upon demand lengthening life of components and reducing energy demand. The contractor I'm planning to use plans to put the air handler/return above our closet upstairs. It will be a dual zone/split system with electric doors to upper and lower floor ductwork via upper and lower floor thermostats.

I know that every home needs calculations for "R" factors for walls,windows...but with the Bosch 3 ton unit it works with any home needing 1.5-3 ton unit. Mine needs about 2.5-3 so it will be the 3 ton.

My main concern now is that the contractor correctly figures the cubic feet per minute and such for each room or living area and the correct placement of the return.

He says he plans to install one return upstairs. It will be about 2/3 up the 17' vaulted wall dividing our living room from our bed/bath area. He also plans to install the registers for heating/cooling on that same wall....one about 8' away on each side of the return and a few feet lower on the wall.

Here's a link to a thread here on the forum which better describes the home

House build start to finish

Reason for one return is that the stairway is open to the basement

Any opinions appreciated as this system will be installed next week.

Thanks, Dan